A high-efficiency treatment method for high-voltage waste lithium batteries

A technology for waste lithium batteries and a treatment method is applied in the field of high-efficiency treatment of high-voltage waste lithium batteries, which can solve the problems of difficulty, the electrolyte cannot be effectively used, and takes up a lot of time, so as to improve the treatment efficiency and production capacity, and save the Effects of discharge pretreatment process, efficient separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

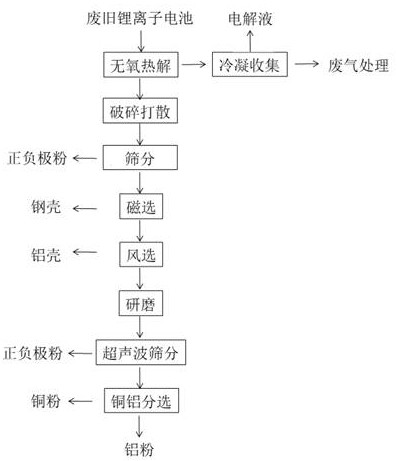

[0026] The processing method of waste and old 18650 lithium-ion battery comprises the following steps:

[0027] a. Put the waste 18650 steel case lithium-ion battery without discharge pretreatment into the pyrolysis furnace, feed nitrogen at the same time, heat to 450°C for anaerobic pyrolysis for 15 minutes, and the electrolyte inside the battery during the anaerobic pyrolysis process It quickly turns into steam, which increases the internal pressure of the battery and opens the battery safety valve until the electrolyte steam is sprayed out. The electrolyte steam is condensed through the pipeline to the condenser, and the removal rate of the electrolyte reaches 95.5% during this process; , binders and other organic substances are pyrolyzed, and the pyrolysis rate of the separator reaches 90.4%, which realizes the rapid release and disappearance of the electric energy inside the battery, causing the battery to fail, and the pyrolyzed battery is obtained; the exhaust gas genera...

Embodiment 2

[0032] The processing method of waste 32650 lithium ion battery comprises the following steps:

[0033] a. Send the waste 32650 steel case lithium-ion battery without discharge pretreatment into the pyrolysis furnace, and at the same time, pass in carbon dioxide, heat it to 500°C for anaerobic pyrolysis for 20 minutes, and the electrolyte inside the battery during the anaerobic pyrolysis process It quickly turns into steam, which increases the internal pressure of the battery and opens the battery safety valve until the electrolyte steam is sprayed out. The electrolyte steam passes through the pipeline to condense in the condenser, and the removal rate of the electrolyte reaches 96.3% during this process; , binders and other organic substances are pyrolyzed, and the pyrolysis rate of the separator reaches 91.7%, realizing the rapid release and disappearance of the electric energy inside the battery, causing the battery to fail, and the pyrolyzed battery is obtained; the waste g...

Embodiment 3

[0038] The processing method of waste and old 42700 lithium-ion batteries comprises the following steps:

[0039] a. Send the waste 42700 steel case lithium-ion battery without discharge pretreatment into the pyrolysis furnace, and at the same time pass in argon gas, heat it to 600°C for anaerobic pyrolysis for 25 minutes, and the electrolysis inside the battery during the anaerobic pyrolysis process The liquid quickly turns into steam, which increases the internal pressure of the battery and then opens the battery safety valve until the electrolyte steam is sprayed out, and the electrolyte steam is condensed in the condenser through the pipeline, and the removal rate of the electrolyte reaches 97.1% during this process; The separator, binder and other organic substances are pyrolyzed, and the pyrolysis rate of the separator reaches 92.0%, which realizes the rapid release and disappearance of the electric energy inside the battery, causing the battery to fail, and the pyrolyzed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com