Preparation method and application of cobalt nickel phosphorus sulfide heterostructure nanosheet

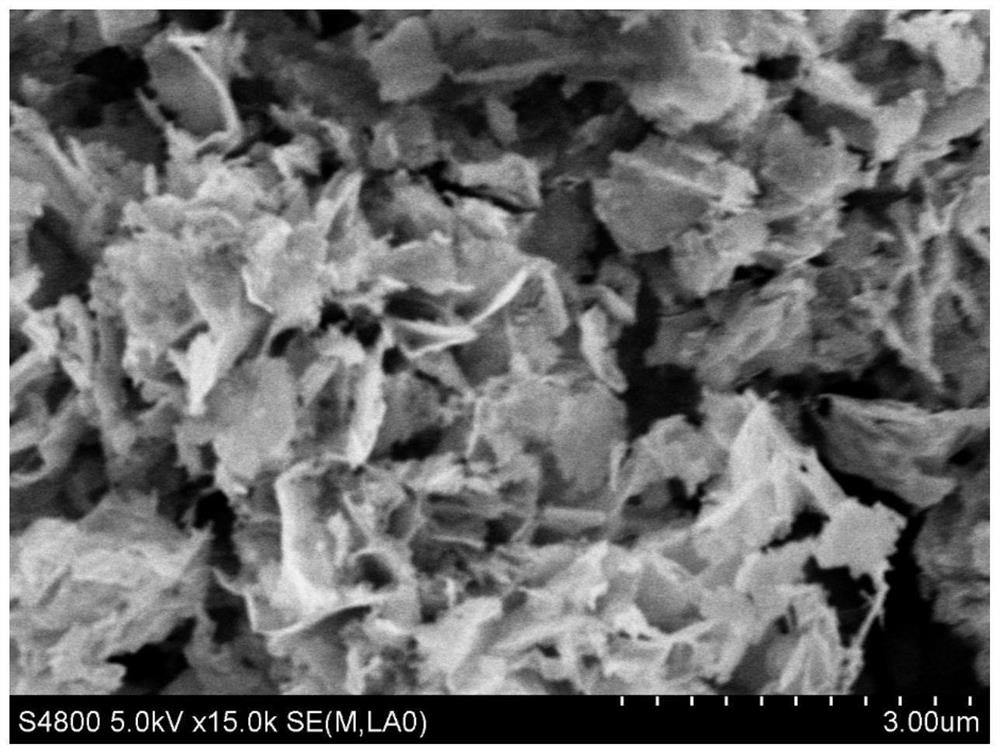

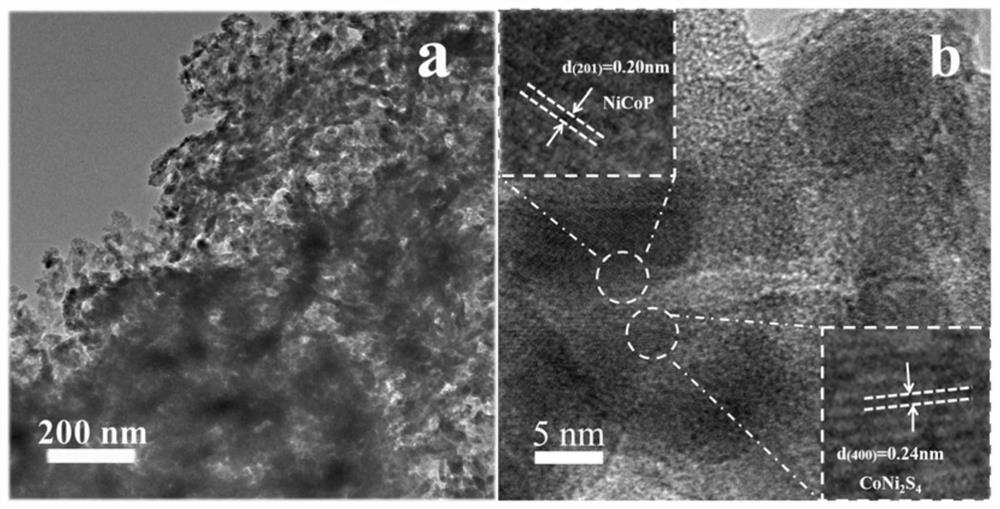

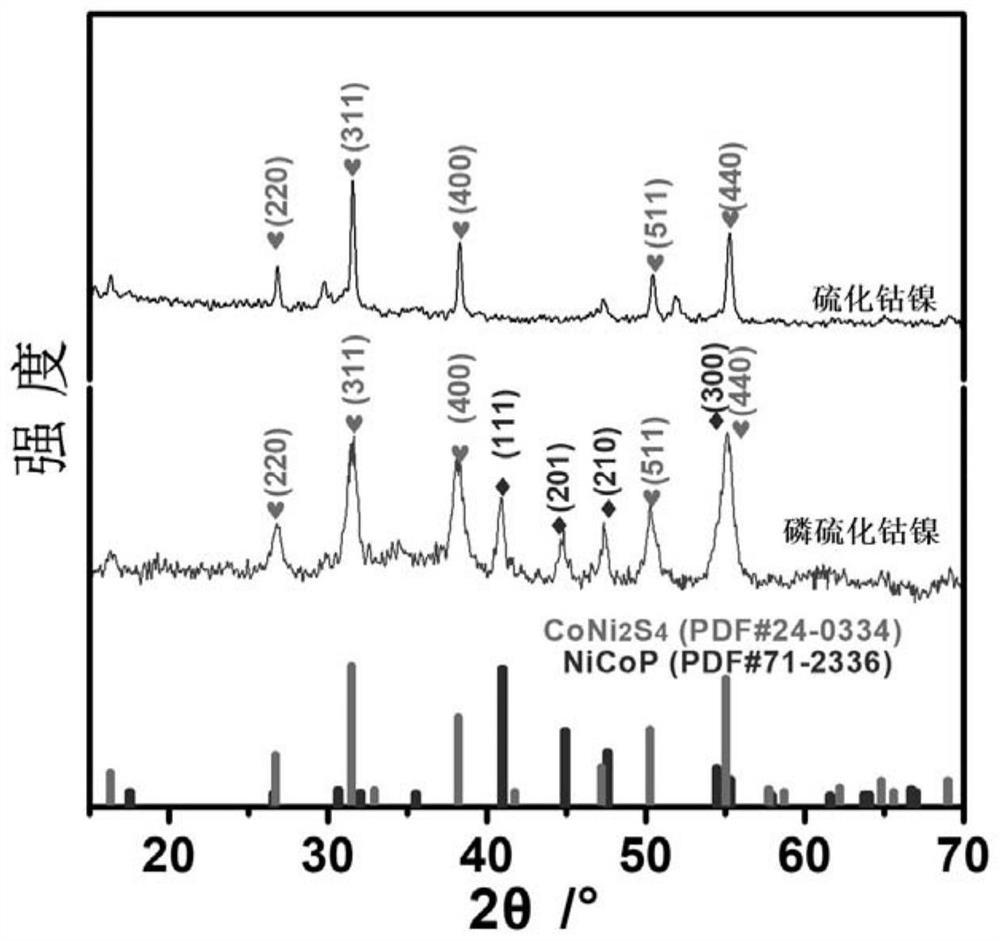

A technology of cobalt-nickel phosphide and heterostructure is applied in the preparation field of cobalt-nickel phosphide, which can solve the problems of reduced synergy between phosphorus and sulfur, low capacitance performance, low phosphorus and sulfur elements, etc., and achieves low cost and simple method. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Specific embodiment 1: In this embodiment, a method for preparing cobalt-nickel sulfide heterostructure nanosheets is completed according to the following steps:

[0030] 1. Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O is dissolved in polyethylene glycol 200, and the reaction is stirred to obtain the reaction solution I;

[0031] 2. Sodium acetate was dissolved in polyethylene glycol 200, and then stirred for reaction to obtain reaction solution II;

[0032] 3. Dissolving thiourea into polyethylene glycol 200, ultrasonically dispersing, and then stirring to react to obtain reaction liquid III;

[0033] 4. Mix the reaction solution I, the reaction solution II and the reaction solution III, and then stir the reaction to obtain a mixed solution; transfer the mixed solution to a high-pressure reactor, and perform a hydrothermal reaction at 180°C to 220°C to obtain a reaction solution IV;

[0034] The volume ratio of reaction solution I, reaction solution II and reacti...

specific Embodiment approach 2

[0037] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 The molar ratio of O is (10~30):(10~30); Ni(NO 3 ) 2 ·6H 2 The volume ratio of the amount of O to polyethylene glycol 200 is (10mmol-30mmol):(10mL-30mL). Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the stirring reaction speed described in step 1 is 60r / min-120r / min, and the stirring reaction time is 20min-40min.

[0039] Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com