Preparation method of alumina porous ceramic

A technology of porous ceramics and alumina, which is applied in the field of ceramics, can solve the problems of low strength of alumina porous ceramics and achieve the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

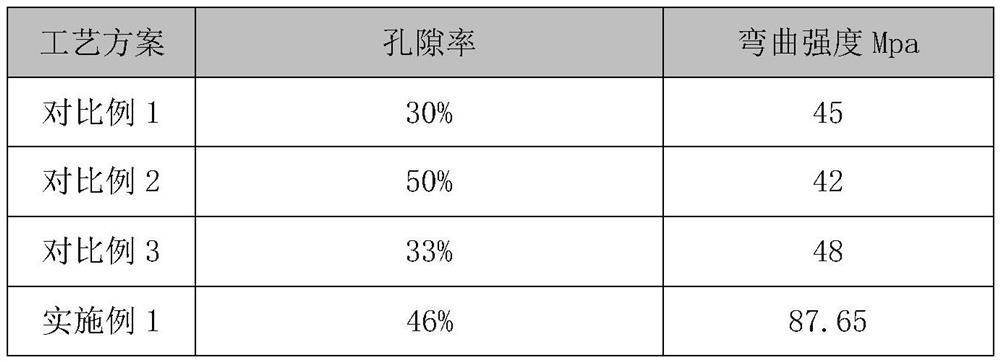

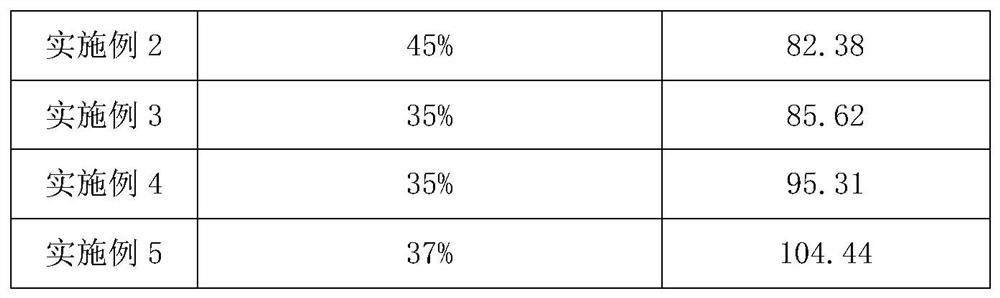

Examples

Embodiment 1

[0030] (1) Mix 25 parts of alumina fine powder with 18 parts of water, add 0.3 parts of dispersant polyacrylic acid, 1.48 parts of monomer N-methylolacrylamide, and cross-linking agent N, N'-methylenebispropylene 0.01 part of amide and 0.01 part of initiator ammonium persulfate, ball milled for 20 minutes; the average particle size of alumina fine powder is 0.8-1.0um;

[0031] (2) After ball milling, 25 parts of alumina coarse powder, 6 parts of sintering aid kaolin, 25 parts of pore-forming agent carbon powder, 0.1 part of a mass concentration of 0.1% sodium carboxymethylcellulose aqueous solution, polyether Type defoamer (GPES type) 0.1 part, add to the slurry after ball milling in step (1), stir for 20 minutes to a uniform state; the average particle size of alumina coarse powder is 3.2-3.6um;

[0032] (3) Put it into the defoaming machine, vacuum defoaming; the vacuum degree during vacuum defoaming is set to -0.1Mpa, and the defoaming time is 30 minutes; then the slurry af...

Embodiment 2

[0035] (1) Mix 20 parts of alumina fine powder with 20 parts of water, add 0.3 parts of dispersant polyacrylic acid, 1 part of monomer N-methylolacrylamide, and cross-linking agent N, N'-methylenebispropylene 0.06 part of amide and 0.06 part of initiator ammonium persulfate, ball milled for 30 minutes; the average particle size of alumina fine powder is 1.5-2um;

[0036] (2) After ball milling, successively with 20 parts of alumina coarse powder, 4 parts of sintering aid silicon micropowder and 2 parts of potassium feldspar, 30 parts of pore-forming agent polymethyl methacrylate, suspending agent is that the mass concentration is 0.5% Add 0.28 parts of carboxymethylcellulose sodium aqueous solution and 0.3 parts of polyether type defoamer (GPES type) to the slurry after ball milling in step (1), and stir for 10 minutes to a uniform state; the average particle size of alumina coarse powder is 8 -10um.

[0037] (3) Put it into the degassing machine, vacuum degassing; the vacuum...

Embodiment 3

[0040] (1) Mix 22 parts of alumina fine powder with 19 parts of water, add 0.5 parts of dispersant polyacrylic acid, 1 part of monomer N-methylol acrylamide, and cross-linking agent N, N'-methylenebispropylene 0.05 part of amide and 0.05 part of initiator ammonium persulfate, ball milled for 25 minutes; the average particle size of alumina fine powder is 1-1.5um.

[0041] (2) After ball milling, 23 parts of alumina coarse powder, 6 parts of sintering aid kaolin and 2 parts of albite, 10 parts of pore-forming agent starch and 18 parts of sawdust, and suspending agent are carboxymethyl Add 0.4 parts of cellulose sodium aqueous solution and 0.2 parts of polyether type defoamer (GPES type) to the slurry after ball milling in step (1), and stir for 15 minutes to a uniform state; the average particle size of alumina coarse powder is 6-8um.

[0042] (3) Put it into the degassing machine, vacuum degassing, the vacuum degree during vacuum degassing is set to -0.1Mpa, and the degassing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com