Preparation method and production device of Guerbet alcohol ether

A Guerbet alcohol and production device technology, which is applied in the field of preparation of Guerbet alcohol ether, can solve the problems of difficult to generate high molecular weight products, long reaction time, increase of by-products, etc., and achieve shortening of reaction residence time, The effect of improving product selectivity and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

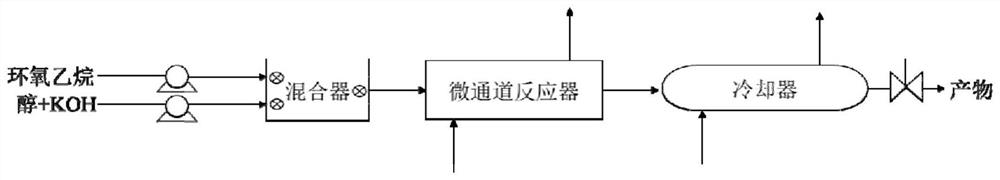

[0027] The invention provides a kind of preparation method of Guerbet alcohol ether, comprises the steps:

[0028] Mixing Guerbet alcohol, potassium hydroxide and ethylene oxide in a mixer to obtain a mixture;

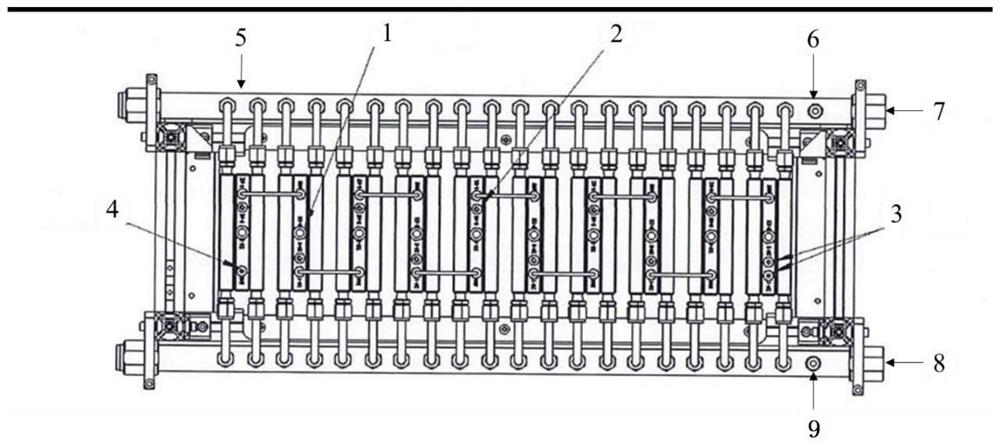

[0029] Transfer the mixture into a microchannel reactor and react for 0.5 to 1.5 minutes under the conditions of 140°C to 200°C and 1MPa to 6MPa to obtain Guerbet alcohol ether;

[0030] The amount of potassium hydroxide added is 1.0‰~4.0‰ of the total mass of Guerbet alcohol and ethylene oxide.

[0031] In the present invention, Guerbet alcohol, potassium hydroxide and ethylene oxide are mixed in a mixer to obtain a mixture. In the present invention, the Guerbet alcohol is preferably a Guerbet alcohol with 12-18 carbon atoms. In the present invention, the molar ratio of the Guerbet alcohol to ethylene oxide is preferably 1:2˜1:9. In the present invention, the amount of potassium hydroxide added is 1.0‰ to 4.0‰ of the total mass of Guerbet alcohol and ethylene oxide...

Embodiment 1

[0042] Preparation of C12 Guerbet alcohol ethers (EO=2).

[0043] 3‰ of the catalyst was dissolved in C12 Guerbet alcohol (M=188 g / mol). The Guerbet alcohol and the ethylene oxide that dissolves catalyst are beat in the mixer by plunger pump respectively and mix, and the mixture that obtains is passed in the microchannel reactor (setting the temperature of microchannel reactor is 190°C, control the reaction pressure to 3Mpa, and the reaction residence time to 1min).

[0044] Using n-nonanol as an internal standard to measure the content of free alcohol in the product obtained by the reaction, the conversion rate of C12 Guerbet alcohol was 73.2%. The hydroxyl value was measured and the average EO adduct number was calculated to be 2.08.

Embodiment 2

[0046]The preparation product and method are the same as in Example 1, except that the temperature of the microchannel reactor is set at 165°C, the reaction pressure is controlled at 6Mpa, and the residence time of the reaction is 1.5min. Using n-nonanol as an internal standard to measure the content of free alcohol in the product obtained by the reaction, the conversion rate of C12 Guerbet alcohol was 72.76%. The hydroxyl value was measured and the average EO adduct number was calculated to be 2.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com