Process for extracting picroside from rhizoma picrorhizae through fermentation

A technology of picroside and picroside, applied in the field of fermentative extraction of picroside, can solve the problems of low extraction efficiency of picroside total saponins, unstable process and the like, and achieve stable properties, strong systemicity and good reproducibility of separated products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

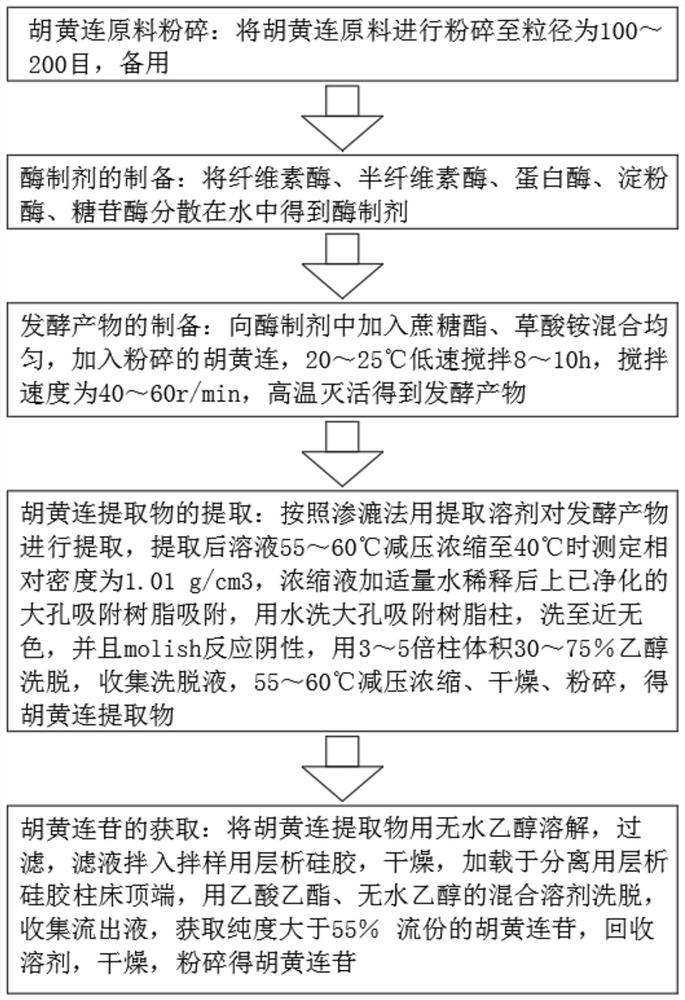

[0029] Such as figure 1 Shown, a kind of technology that extracts berberine from fermented berberine, comprises the following steps:

[0030] Step 1. Crush the raw material of Coptis chinensis: crush the raw material of Coptis chinensis to a particle size of 100-200 meshes, and set aside. rhizome;

[0031] Step 2, preparation of enzyme preparation: disperse cellulase, hemicellulase, protease, amylase, glycosidase in water to obtain enzyme preparation, the concentration of cellulase is 14u / g, and the concentration of hemicellulase is 20u / g, the concentration of protease is 2u / g, the concentration of amylase is 3u / g, and the concentration of glycosidase is 2u / g;

[0032] Step 3. Preparation of fermentation product: add sucrose ester and ammonium oxalate to the enzyme preparation, mix evenly, add crushed Rhizoma Peptides, stir at a low speed of 20°C for 8 hours at a stirring speed of 40r / min, and inactivate at a high temperature to obtain a fermentation product, enzyme prepara...

Embodiment 2

[0036] Such as figure 1 Shown, a kind of technology that extracts berberine from fermented berberine, comprises the following steps:

[0037] Step 1. Crush the raw material of Coptis chinensis: crush the raw material of Coptis chinensis to a particle size of 100-200 meshes, and set aside. rhizome;

[0038] Step 2, preparation of enzyme preparation: disperse cellulase, hemicellulase, protease, amylase, glycosidase in water to obtain enzyme preparation, the concentration of cellulase is 16u / g, and the concentration of hemicellulase is 23u / g, the concentration of protease is 3u / g, the concentration of amylase is 4u / g, and the concentration of glycosidase is 2.5u / g;

[0039] Step 3. Preparation of fermentation product: add sucrose ester and ammonium oxalate to the enzyme preparation, mix evenly, add crushed Rhizoma Peptides, stir at a low speed of 23°C for 9 hours at a stirring speed of 50r / min, and inactivate at a high temperature to obtain a fermentation product, enzyme prepara...

Embodiment 3

[0043] Such as figure 1 Shown, a kind of technology that extracts berberine from fermented berberine, comprises the following steps:

[0044] Step 1. Crush the raw material of Coptis chinensis: crush the raw material of Coptis chinensis to a particle size of 100-200 meshes, and set aside. rhizome;

[0045] Step 2, preparation of enzyme preparation: disperse cellulase, hemicellulase, protease, amylase, glycosidase in water to obtain enzyme preparation, the concentration of cellulase is 18u / g, and the concentration of hemicellulase is 26u / g, the concentration of protease is 4u / g, the concentration of amylase is 5u / g, and the concentration of glycosidase is 3u / g;

[0046] Step 3. Preparation of fermentation product: add sucrose ester and ammonium oxalate to the enzyme preparation, mix evenly, add crushed Rhizoma Peptides, stir at a low speed of 25°C for 10 hours at a stirring speed of 60r / min, and inactivate at a high temperature to obtain a fermentation product, enzyme prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com