Nano-composite initiator, thickening agent for fracturing fluid and application

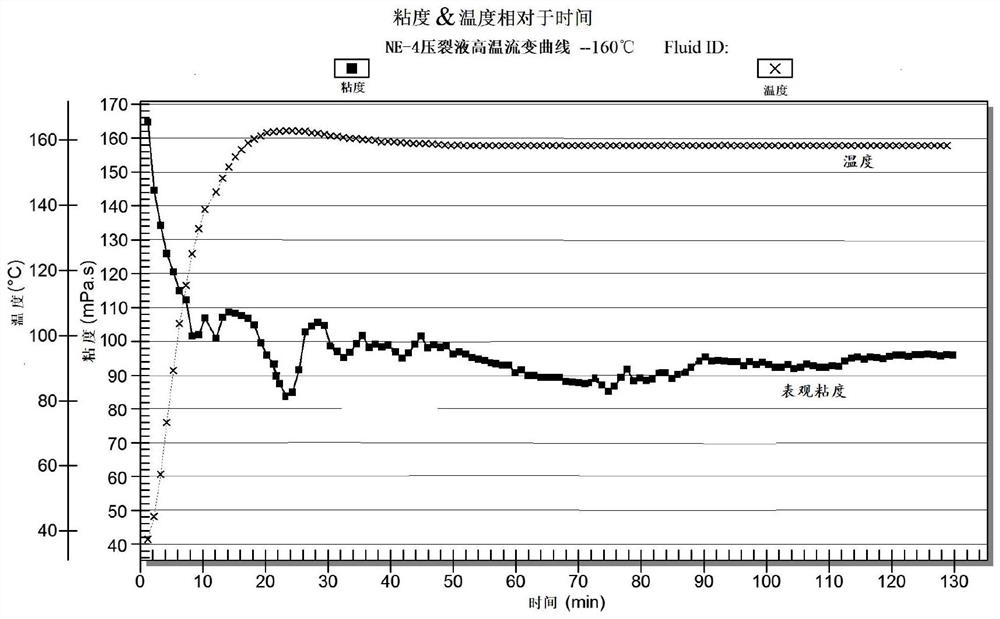

A nano-composite and initiator technology, applied in the fields of organic chemistry, drilling compositions, chemical instruments and methods, etc., can solve the problem of high temperature shearing at 130 ° C, the influence of broken gel formation, and insoluble dissolution. Sufficient and other problems, to achieve the effect of good sand suspension performance, improved high temperature resistance, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0094] Preparation of nanocomposite initiator NSI-1:

[0095] In a 500ml three-necked flask, add 65ml of xylene, then add 12.5g of 3,5-dimethyl-p-hydroxybenzophenone, and 1.25g of tetrabutylammonium bromide, heat it to 45°C, and slowly drop it under stirring Add 24.6 g of epichlorohydrin. Maintain the reaction temperature of 50°C for 6 hours, distill off the solvent under reduced pressure to obtain the intermediate BPCL-1;

[0096] In a 500ml three-necked flask, add 150ml of petroleum ether and 50ml of acetone, then add 4g of nano-silica (the average particle size of nano-silica is 5-20nm), stir and disperse for 30min, and then add 23g of 3-aminopropyl tris Ethoxysilane, react at 50°C for 10h to obtain the intermediate SINH-1;

[0097] In a 500ml three-necked flask, add 60ml of isobutanol, then add 12g of BPCL-1, 13.5g of intermediate SINH-1 and 1.5g of triethanolamine, heat to 60°C, and react for 10h. After the reaction, distill off the solvent to obtain nano Composite ini...

preparation example 2

[0099] Preparation of nanocomposite initiator NSI-2:

[0100] In a 500ml three-necked flask, add 65ml of xylene, then add 14g of 3,5-diethyl-p-hydroxybenzophenone, and 1.3g of tetrabutylammonium bromide, heat to 40°C, and slowly add dropwise under stirring 23.2 g of epichlorohydrin. Maintain the reaction temperature of 50°C for 7 hours, distill off the solvent under reduced pressure to obtain the intermediate BPCL-2;

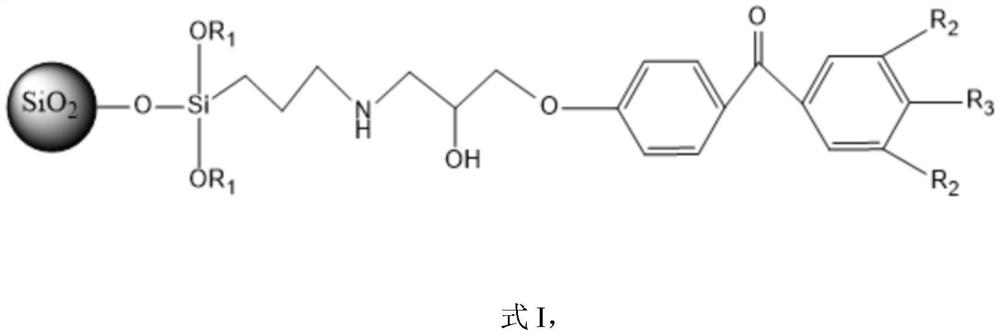

[0101] In a 500ml three-neck flask, add 60ml of butanol, then add 11g of BPCL-2, 13g of intermediate SINH-1 and 1.5g of triethanolamine, heat to 60°C, and react for 10h. Agent NSI-2 (structure is shown in formula I, wherein R 1 is ethyl, R 2 is ethyl, R 3 for hydrogen).

preparation example 3

[0103] Preparation of nanocomposite initiator NSI-3:

[0104] In a 500ml three-necked flask, add 65ml of xylene, then add 12g of p-hydroxybenzophenone, and 1.2g of tetrabutylammonium bromide, after heating to 40°C, slowly add 23.6g of epichlorohydrin dropwise under stirring, Maintain the reaction temperature of 50°C for 7 hours, distill off the solvent under reduced pressure to obtain the intermediate BPCL-3;

[0105] In a 500ml three-neck flask, add 20ml of acetone and 50ml of butanol, then add 10g of BPCL-3, 12.6g of intermediate SINH-1 and 1.6g of triethylamine, heat to 55°C, react for 10h, and distill off the solvent after the reaction , to obtain nanocomposite initiator NSI-3 (structure shown in formula I, wherein R 1 is ethyl, R 2 for hydrogen, R 3 for hydrogen).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com