Ester polycarboxylic acid water reducer with low hydration heat and preparation method thereof

An ester polycarboxylic acid, low hydration heat technology, applied in the field of concrete admixtures, can solve problems such as poor adaptability and non-condensation of concrete, and achieve the effects of easy operation, reducing hydration heat, and maintaining slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

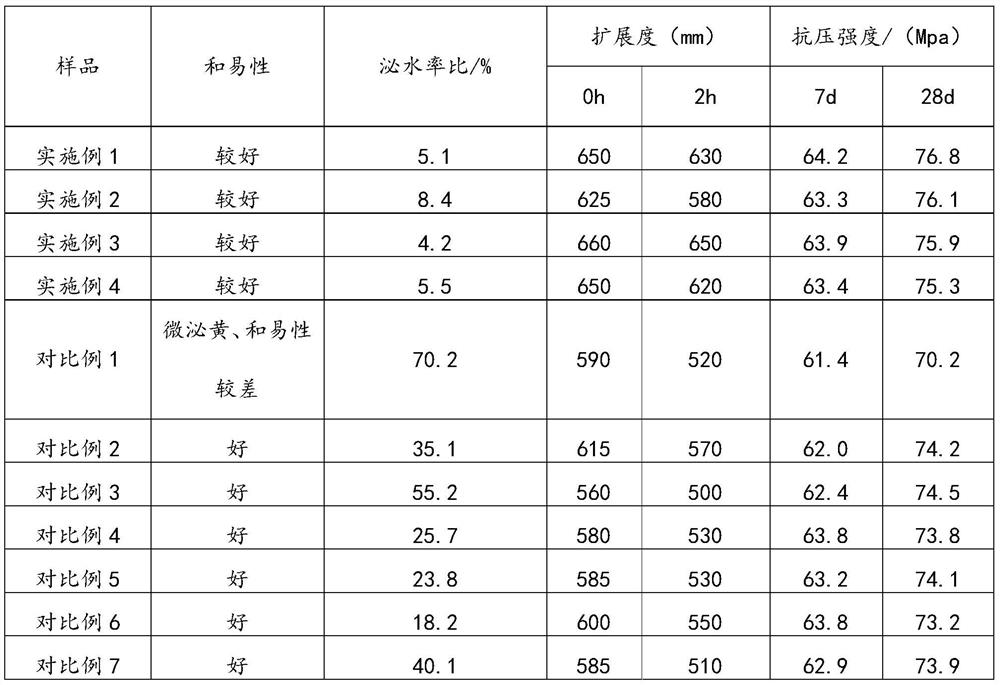

Examples

Embodiment 1

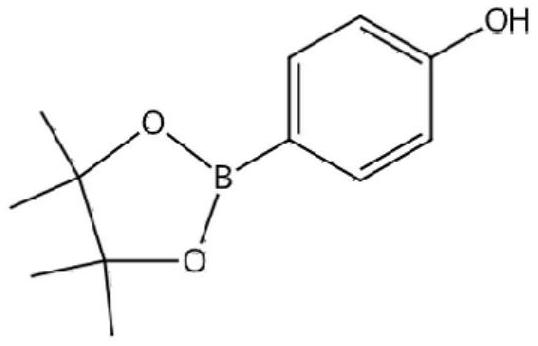

[0037] Preparation of A1 esterification product: in parts by weight, 117.2 parts of methacrylic acid and 100 parts of 4-hydroxyphenylboronic acid pinacidate were added to the first reaction vessel for mixing, and under nitrogen protection conditions, 3.3 parts of p-toluenesulfonic acid were added, 4.3 parts of methyl hydroquinone, and adjust the reaction temperature to 120°C, and react for 5 hours to obtain the esterified product;

[0038] A2 copolymerization reaction: in parts by weight, first with 3.5 parts of esterification products made in step A1, 100 parts of polyethylene glycol monomethacrylate with a molecular weight of 5000, 0.8 parts of polyoxyethylene sorbitol tetraoleate and Add 121 parts of water into the second reaction vessel and stir evenly, mix 2 parts of hydrogen peroxide and 20 parts of water in the first dropping device; mix 0.5 parts of ascorbic acid, 1.5 parts of thioglycolic acid and 20 parts of water in the second dropping device Medium; Mix 8 parts of ...

Embodiment 2

[0041] Preparation of B1 esterification product: in parts by weight, add 130 parts of acrylic acid and 100 parts of 4-hydroxyphenylboronic acid pinacolate into the first reaction vessel and mix them. Under nitrogen protection conditions, add 1.84 parts of concentrated sulfuric acid and 6.9 parts of diphenylamine , and adjust the reaction temperature to 125°C, and react for 4 hours to obtain the esterification product;

[0042] B2 copolymerization reaction: in parts by weight, first prepare 2 parts of the esterification product obtained in step B1, 100 parts of monomethoxy ether monoacrylate polyethylene glycol with a molecular weight of 3000, and 0.5 part of sorbitol polyoxyethylene ether tetra-oil Ester and 125 parts of water, add to the second reaction container and stir evenly, 3 parts of sodium persulfate and 20 parts of water are mixed evenly in the first dropping device; 2 parts of sodium hypophosphite, 2 parts of n-butyl mercaptan and 20 parts Water is mixed uniformly i...

Embodiment 3

[0045] Preparation of C1 esterification product: In parts by weight, 59 parts of methacrylic acid and 100 parts of 4-hydroxyphenylboronic acid pinacidate were added to the first reaction vessel for mixing, and under nitrogen protection conditions, 3.9 parts of cerium sulfate, 2.4 parts of Diphenylamine, and adjust the reaction temperature to 130°C, and react for 5h to obtain the esterification product;

[0046] C2 copolymerization reaction: in parts by weight, 5 parts of the esterification product prepared in step C1, 100 parts of monomethoxy ether monomethacrylate polyethylene glycol with a molecular weight of 3000, and 1.5 parts of sorbitol polyoxyethylene ether Tetraoleate and 119 parts of water are added into the second reaction vessel and stirred evenly, 1 part of potassium persulfate and 20 parts of water are mixed evenly in the first dropping device; 1.5 parts of 2-hydroxy-2-sulfinic acid Disodium salt, 0.8 parts of 3-mercaptopropionic acid and 20 parts of water are mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com