LED light-cured insulating paint capable of being directly welded and preparation method of LED light-cured insulating paint

An insulating varnish and light-curing technology, which is applied in the direction of insulators, coatings, electrical components, etc., can solve the problems of increasing process steps, no replacement, increasing labor costs and work efficiency of downstream customers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 prepares polyester polyol

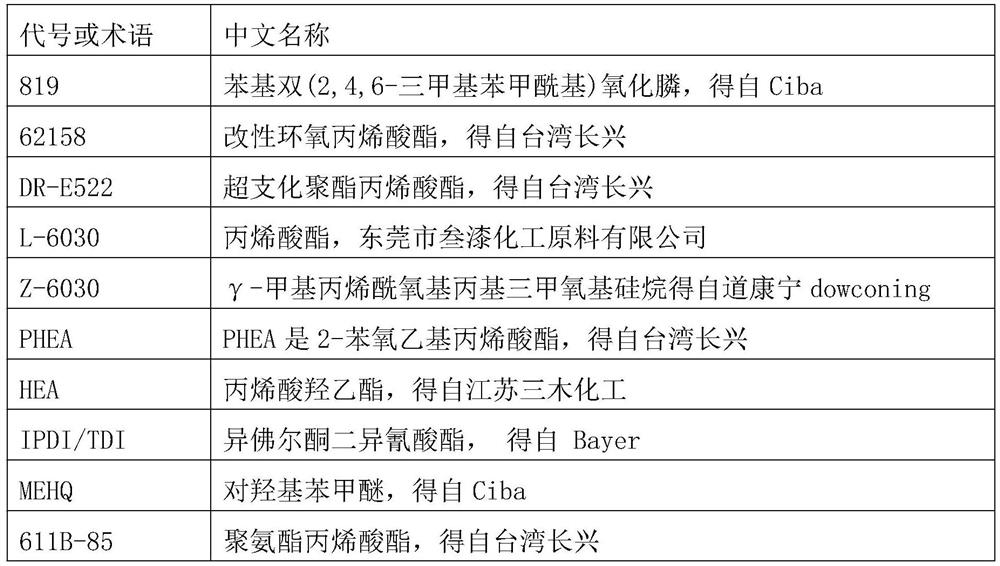

[0040] The coating is prepared according to the formula in Table 1.

[0041] JZC-1 JZC-2 1 Phthalic acid 55.00 51.50 2 Adipic acid 11.80 16.5 3 ethanolamine 5.5 4.0 4 Ethylene glycol 24.0 27.0 5 Trimethylolpropane 3.2 3.0 total 100.0 100.0

[0042]First put 1, 2, 3, 4, 5 into the reaction kettle according to the proportion, heat up and stir, when the temperature reaches 160°C, start to add antioxidant, pass nitrogen and xylene, react at 200°C for 12-15 hours, acid When the value is <3mgKOH / g, stop heating, vacuumize for 1h, remove xylene and water, and obtain light yellow viscous hydroxyl-terminated polyester with a molecular weight of about 2000g / mol.

Embodiment 2

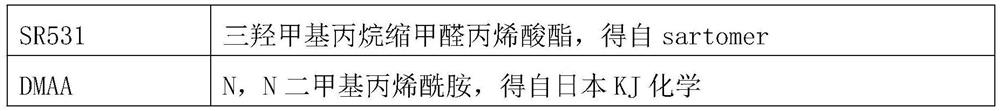

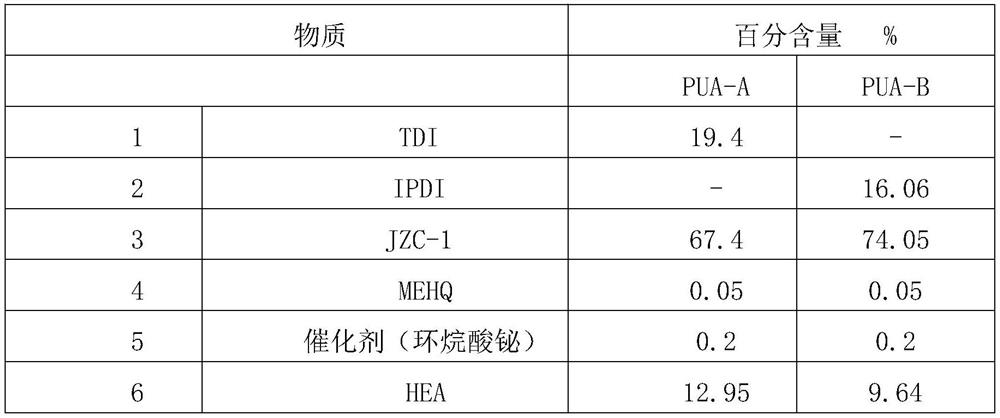

[0043] Embodiment 2 prepares polyurethane acrylate

[0044]

[0045] First, add self-made polyester polyol JZC-1 and catalyst to the isocyanate, control the reaction temperature at 65-68°C for 2 hours, then add HEA, catalyst, and polymerization inhibitor dropwise, control the reaction temperature at 75-78°C for 2.5 hours, and test The isocyanate value is less than 1%, and the product can be obtained.

[0046]

[0047]

[0048] First, add self-made polyester polyol JZC-2 and catalyst to the isocyanate, control the reaction temperature at 65-68°C for 2 hours, then add HEA, catalyst and polymerization inhibitor dropwise, control the reaction temperature at 75-78°C for 2.5 hours, test The isocyanate value is less than 1%, and the product can be obtained.

Embodiment 3

[0049] Embodiment 3 prepares the UV-LED photocurable insulation coating that can be directly welded

[0050] 3-A 3-B 3-C 3-D 3-E 1 611B-85 35.0 - - - - 2 PUA-A - 35.0 - - - 3 PUA-B - - 35.0 - - 4 PUA-C - - - 35.0 - 5 PUA-D - - - - 35.0 6 DR-E522 5.0 5.0 5.0 5.0 5.0 7 L-6030 8.0 8.0 8.0 8.0 8.0 8 62158 8.0 8.0 8.0 8.0 8.0 9 SR531 19.0 19.0 19.0 19.0 19.0 10 DMAA 5.5 5.5 5.5 5.5 5.5 11 PHEA 16.0 16.0 16.0 16.0 16.0 12 TPO 0.5 0.5 0.5 0.5 0.5 13 819 1.5 1.5 1.5 1.5 1.5 14 Z-6030 1.0 1.0 1.0 1.0 1.0 15 Auxiliary 0.5 0.5 0.5 0.5 0.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com