Electrolytic polishing solution and electrolytic polishing process for titanium alloy EBSD sample

An electrolytic polishing and titanium alloy technology, which is applied in the field of electrolytic polishing liquid and electrolytic polishing technology, can solve the problems of poor calibration rate stability of polishing technology, not easy to prepare, complicated components, etc., and achieve easy preparation and storage, bright and clean surface, The effect of bright and clean surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

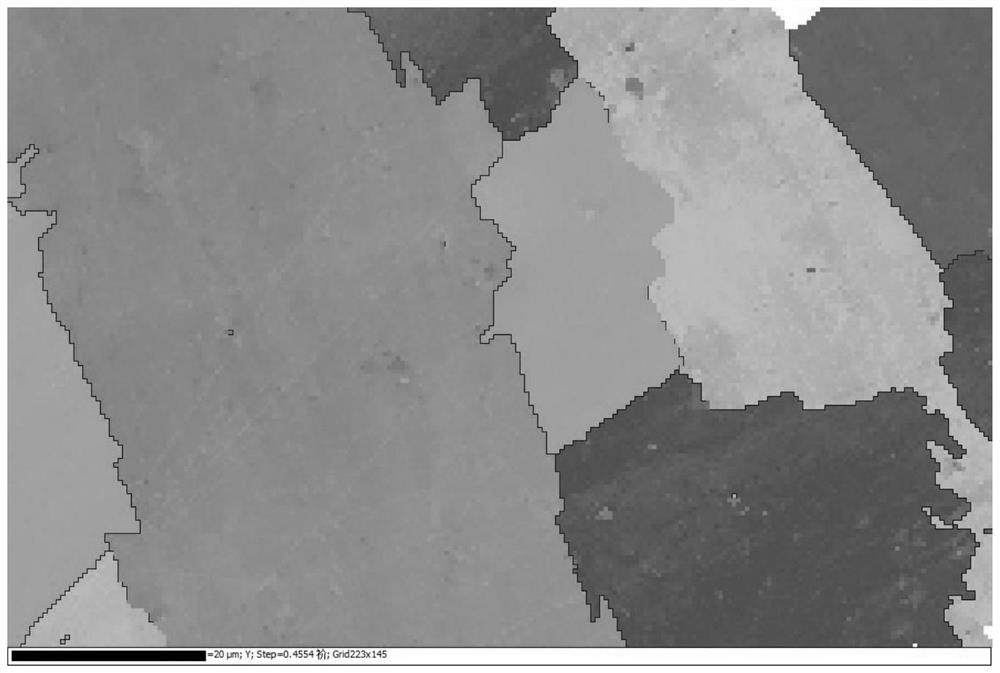

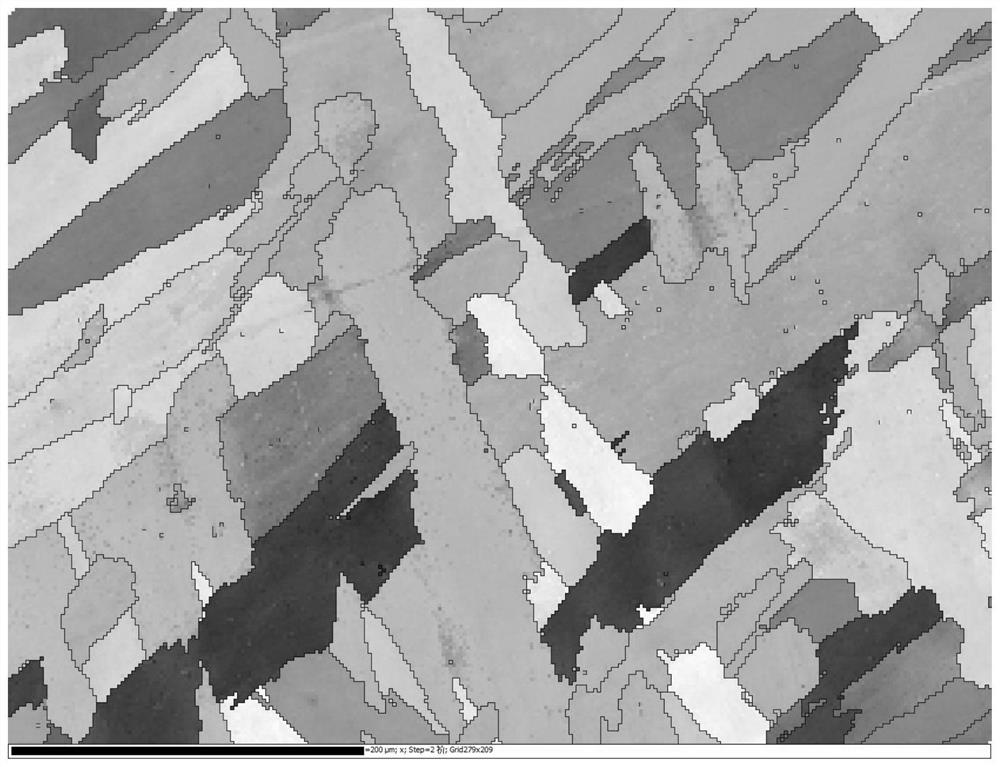

Image

Examples

Embodiment

[0026] In this example, the surface grinding and polishing treatment of arc 3D printed Ti-6Al-4V titanium alloy includes the following steps:

[0027] (1) After the wire-cut titanium alloy sample is inlaid, it is mechanically polished by 240#, 400#, 600#, 800#, 1000#, 1200#, 1500#, 2000#, 3000#, 5000# sandpaper; And every time a piece of sandpaper is changed, the titanium alloy sample is rotated 90° for grinding to ensure that the scratches on the previous layer are covered;

[0028] (2) Polish the mechanically polished titanium alloy sample on a polishing machine, adjust the speed to 300r / min, and keep dropping the pre-prepared SiO2 containing a small amount of hydrogen peroxide during the polishing process. 2 Suspension; as the polishing process progresses, the speed is gradually adjusted to 100r / min until the bright mirror surface is thrown out, and then the inlay on the titanium alloy sample is carefully removed to prevent scratching the bright mirror surface;

[0029] (3...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is:

[0037] In step (2), as the polishing process progresses, the rotating speed is gradually adjusted to 130r / min until the bright mirror surface is thrown out;

[0038] In step (3), each liter of electropolishing liquid comprises each component of following content: 40ml perchloric acid, 300ml n-butanol, 550ml methyl alcohol and 110ml hydrogen peroxide solution;

[0039] In step (3-3), the voltage of the DC power supply is adjusted to 26V, and the temperature of the electrolytic polishing solution is controlled at 0°C; the current during the electrolysis process is controlled at about 1.5A, and the polishing time is controlled at 15s.

[0040] Others are with embodiment 1.

Embodiment 3

[0042] The difference between this embodiment and embodiment 1 is:

[0043] In step (2), as the polishing process progresses, the rotating speed is gradually adjusted to 150r / min until the bright mirror surface is thrown out;

[0044] In step (3), each liter of electropolishing liquid comprises each component of following content: 60ml perchloric acid, 400ml n-butanol, 450ml methyl alcohol and 90ml hydrogen peroxide solution;

[0045] In step (3-3), the voltage of the DC power supply is adjusted to 28V, and the temperature of the electrolytic polishing solution is controlled at 25°C; the current during the electrolysis process is controlled at about 1.8A, and the polishing time is controlled at 5s.

[0046] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com