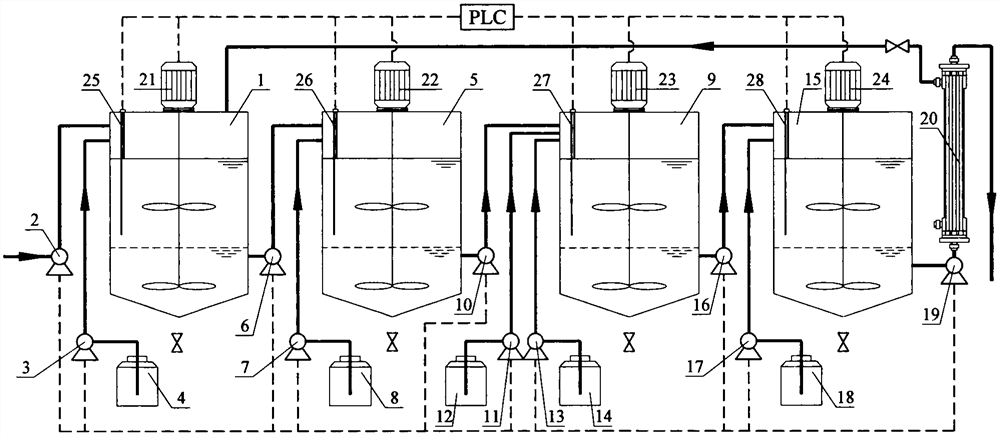

System for treating cobalt-60 wastewater through two-stage induced crystallization and ultrafiltration

A technology for inducing crystallization and wastewater, applied in nuclear engineering, radioactive purification, etc., can solve the problems of inability to significantly reduce the pollution of ultrafiltration membranes, increase the difficulty and cost of treatment, and fine particles of insoluble salts, and achieve good solid-liquid separation effect. The effect of good environmental benefit and good economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Inducing the volume fraction of 2% induced by 2% in the primary and secondary induced crystalline reactor, and the molar ratio is 2: 1. Stable cobalt chloride was added to the simulated cobalt-60 wastewater of the primary isotope mixing tank, and the cobalt concentration was 5.0 mg / L, and the primary induced crystalline reactor was induced by mixing for 2 minutes, and induced the crystallization reactor to add 150 mg / L's NaOH, at 120S -1 The collision intensity was carried out for 20 min, precipitate 13 min, discharged into a secondary isotope mixing tank, and adjusted pH to 8.5 through hydrochloric acid, cobalt cobalt chloride to cobalt concentration of 5.0 mg / L, mixed for 2min as two Class-induced crystalline reactor water, add 120 mg / L NaOH to the secondary induced crystalline reactor, at 120s -1 The collision intensity was carried out for 20 min, precipitated for 13 min, discharged into the ultrafiltration unit, and was discharged after filtration of the ultrafil...

Embodiment 2

[0030] The volume fraction (calcium carbonate and cobalt hydroxide) induced by 3% in the primary and secondary induced crystalline reactor, and the molar ratio was 3: 1. Stable cobalt chloride was added to the simulated cobalt-60 wastewater of the primary isotope mixing tank, and the cobalt concentration was 5.4 mg / L, and the first stage induced crystalline reactor was transferred to the primary induced crystallization reactor to add 150 mg / L's NaOH, at 120S -1 The collision intensity was carried out for 20 min, precipitated for 10 min, discharged into a secondary isotope mixing tank, and adjusted pH to 8.8 by hydrochloric acid, cobalt chloride to cobalt concentration of 5.4 mg / L, mixed for 3 minutes as two Level induced crystalline reactor into water, add 60 mg / L NaOH in the secondary induced crystalline reactor, at 120s -1 The collision intensity was crystallized at 20 min, precipitated for 10 min, discharged into the ultrafiltration unit, and was discharged after being ...

Embodiment 3

[0032] The volume fraction (cobalt hydroxide) (cobalt hydroxide) induced by 5% in the crystalline reactor was introduced to the primary and secondary induced crystalline reactor, and the molar ratio was 4: 1. The steady cobalt chloride was added to the simulated cobalt-60 wastewater of the primary isotopic mixing tank, and the cobalt concentration was 5.5 mg / L, and after mixing for 2 min, it entered the primary induced crystalline reactor, and induced the crystalline reactor to add 200 mg / L's NaOH, at 120S -1 The collision intensity is 15 min, precipitated for 10 min, discharge the supernatant into the secondary isotope mixing tank, and the pH is adjusted by hydrochloric acid to 9, and cobalt chloride to cobalt concentration is 5.5 mg / L, mixed for 2min as two Level induced crystalline reactor water, add NaOH of 80mg / L in the secondary induced crystalline reactor, at 120S -1 The collision intensity was reflected for 15 min, precipitated for 10 min, discharged into the ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com