An electrospinning nanofiber membrane loaded with self-assembled traditional Chinese medicine component vesicles and its preparation method and application

A nanofiber membrane and electrospinning technology, applied in the field of pharmaceutical preparations, can solve the problems that dispersible tablets cannot effectively protect the wound surface, cannot guarantee safety, increase the difficulty of treatment, etc., achieve excellent biological properties, and improve drug bioavailability. , the effect of improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

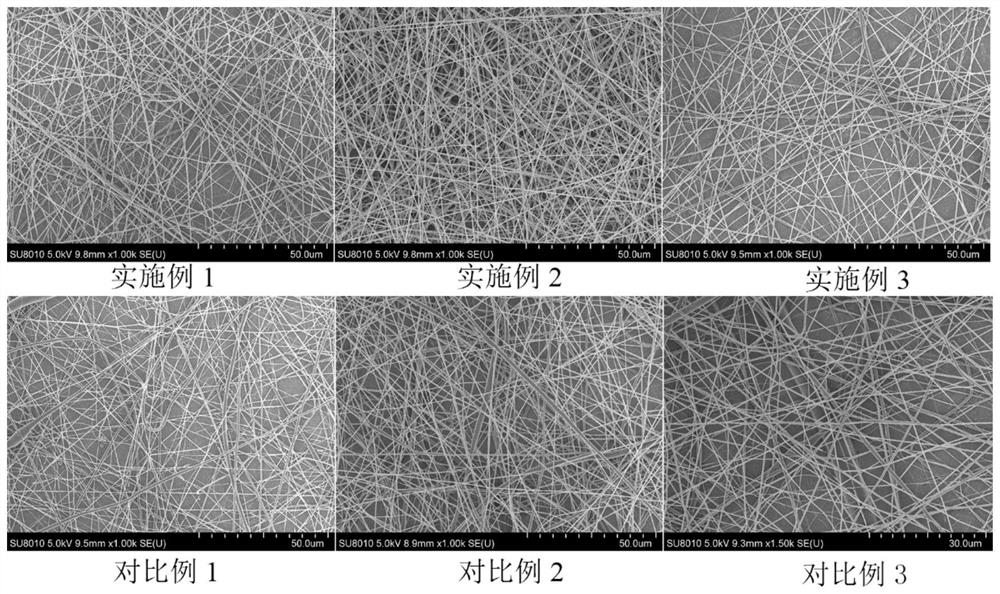

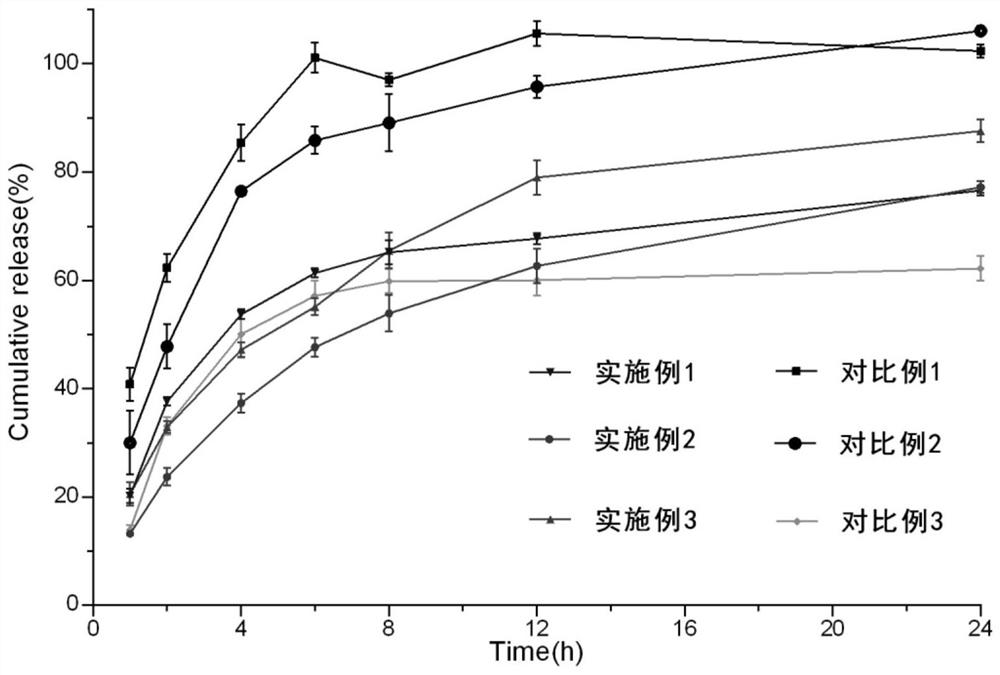

Embodiment 1

[0043] An electrospinning nanofiber membrane loaded with self-assembled traditional Chinese medicine component vesicles, the preparation method comprising the following steps:

[0044] 1. In the dark, slowly add polycaprolactone (PCL) and phospholipid (PC) into the mixed solvent, and stir in a closed place in the dark until completely dissolved, then continue to stir for 3 hours, and finally remove the bubbles by ultrasonic, and the obtained mixed solution is used as a spinning solution. Shell solution of silk material.

[0045] Mixed solvent preparation: dichloromethane (CH 2 CL 2 ) and N-N dimethylformamide (DMF) in a volume ratio of 5:1, stirring and mixing evenly to obtain a mixed solvent.

[0046] In the obtained shell solution, the concentration of polycaprolactone (PCL) was 30% (w / v%) and the concentration of phospholipid (PC) was 4% (w / v%) by mass volume percentage.

[0047] 2. Add polyvinylpyrrolidone (PVP) and centella asiatica total glycosides (CTG) into absolute...

Embodiment 2

[0053] An electrospinning nanofiber membrane loaded with self-assembled traditional Chinese medicine component vesicles, the preparation method comprising the following steps:

[0054] 1. In the dark, slowly add polycaprolactone (PCL) and phospholipid (PC) into the mixed solvent, and stir in a closed place in the dark until completely dissolved, then continue to stir for 3 hours, and finally remove the bubbles by ultrasonic, and the obtained mixed solution is used as a spinning solution. Shell solution of silk material.

[0055] Mixed solvent preparation: dichloromethane (CH 2 CL 2 ) and N-N dimethylformamide (DMF) in a volume ratio of 5:1, stirring and mixing evenly to obtain a mixed solvent.

[0056] In the obtained shell solution, the concentration of polycaprolactone (PCL) was 30% (w / v%) and the concentration of phospholipid (PC) was 8% (w / v%) by mass volume percentage.

[0057] 2. Add polyvinylpyrrolidone (PVP) and centella asiatica total glycosides (CTG) into absolute...

Embodiment 3

[0063] An electrospinning nanofiber membrane loaded with self-assembled traditional Chinese medicine component vesicles, the preparation method comprising the following steps:

[0064] 1. In the dark, slowly add polycaprolactone (PCL) and phospholipid (PC) into the mixed solvent, and stir in a closed place in the dark until completely dissolved, then continue to stir for 3 hours, and finally remove the bubbles by ultrasonic, and the obtained mixed solution is used as a spinning solution. Shell solution of silk material.

[0065] Mixed solvent preparation: dichloromethane (CH 2 CL 2 ) and N-N dimethylformamide (DMF) in a volume ratio of 5:1, stirring and mixing evenly to obtain a mixed solvent.

[0066] In the obtained shell layer solution, the concentration of polycaprolactone is 30% (w / v%) and the concentration of phospholipid (PC) is 8% (w / v%) by mass volume percentage.

[0067] 2. Add polyvinylpyrrolidone (PVP) and centella asiatica total glycosides (CTG) into absolute e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com