Method for preparing vanadium trioxide through liquid-phase hydrogen reduction

A technology of vanadium trioxide and liquid phase, applied in vanadium oxide, chemical recovery and other directions, can solve the problems of limited industrial application, high price of palladium chloride, and high production cost, and achieves low production cost, high purity, and high production cost. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

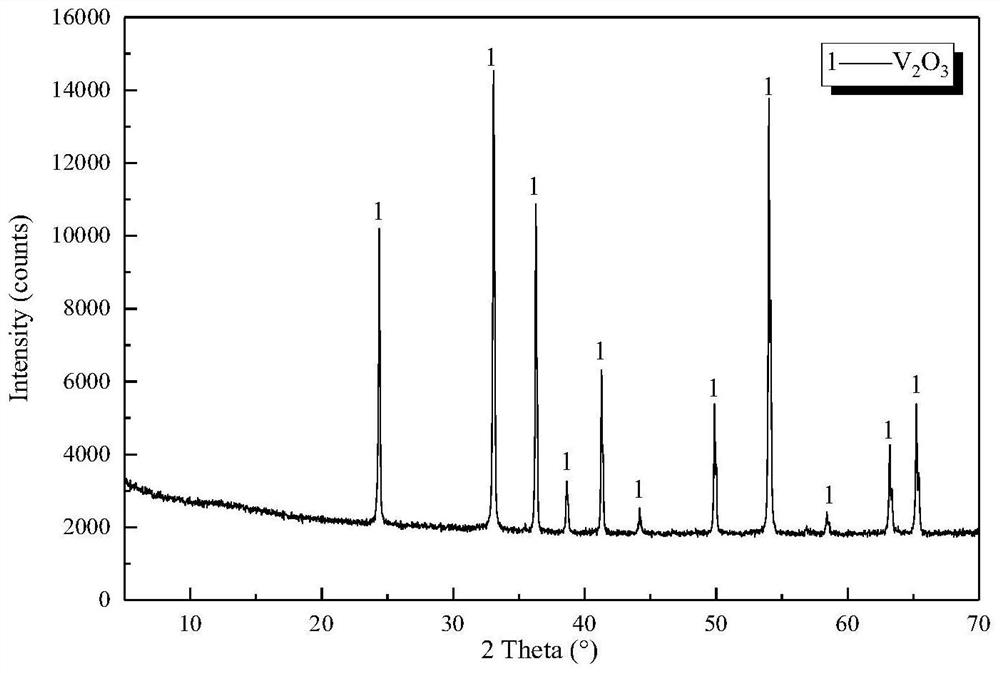

Image

Examples

Embodiment 1

[0028] A method for preparing vanadium trioxide by liquid-phase hydrogen reduction. The specific steps of the method described in this embodiment are as follows:

[0029] Step 1. Completely dissolve the pentavalent vanadium compound with sodium hydroxide solution, and then adjust the pH value to 5-5.5 to obtain a vanadium-enriched liquid; the vanadium concentration of the vanadium-enriched liquid is 0.1-0.4 mol / L.

[0030] Step 2. According to the filling rate of the vanadium-rich liquid in the autoclave is 50-60%, the vanadium-rich liquid is placed in the autoclave; then the solid-liquid ratio is 10-20g / L, and the Add nickel powder into the vanadium-rich liquid as a catalyst; then, under the conditions of temperature 250-260°C, hydrogen partial pressure 3-4MPa and rotation speed 300-400r / min, stir for 2-3h, cool, and release the pressure to obtain Vanadium trioxide slurry.

[0031] Step 3, subjecting the vanadium trioxide slurry to wet magnetic separation under the conditio...

Embodiment 2

[0037] A method for preparing vanadium trioxide by liquid-phase hydrogen reduction. The specific steps of the method described in this embodiment are as follows:

[0038] Step 1. Completely dissolve the pentavalent vanadium compound with sodium hydroxide solution, and then adjust the pH value to 4.5-5 to obtain a vanadium-enriched liquid; the vanadium concentration of the vanadium-enriched liquid is 0.3-0.6 mol / L.

[0039] Step 2. According to the filling rate of the vanadium-rich liquid in the autoclave is 50-60%, the vanadium-rich liquid is placed in the autoclave; then the solid-liquid ratio is 20-30g / L, and the Add nickel powder into the vanadium-rich liquid as a catalyst; then, under the conditions of temperature 260-270°C, hydrogen partial pressure 4-5MPa and rotation speed 400-500r / min, stir for 3-4h, cool, and release the pressure to obtain Vanadium trioxide slurry.

[0040] Step 3, subjecting the vanadium trioxide slurry to wet magnetic separation under the conditio...

Embodiment 3

[0046]A method for preparing vanadium trioxide by liquid-phase hydrogen reduction. The specific steps of the method described in this embodiment are as follows:

[0047] Step 1. Completely dissolve the pentavalent vanadium compound with sodium hydroxide solution, and then adjust the pH value to 4-4.5 to obtain a vanadium-enriched liquid; the vanadium concentration of the vanadium-enriched liquid is 0.5-0.8 mol / L.

[0048] Step 2. According to the filling rate of the vanadium-rich liquid in the autoclave is 40-50%, the described vanadium-rich liquid is placed in the autoclave; then the solid-liquid ratio is 30-40g / L, and the Add nickel powder into the vanadium-rich liquid as a catalyst; then, under the conditions of temperature 270-290°C, hydrogen partial pressure 5-6MPa and rotation speed 500-600r / min, stir for 4-5h, cool, and release the pressure to obtain Vanadium trioxide slurry.

[0049] Step 3, subjecting the vanadium trioxide slurry to wet magnetic separation under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com