Neutron detection glass scintillator and preparation method and application thereof

A scintillator and glass technology, which is applied in the field of neutron detection glass scintillator and its preparation, can solve the problems of uncontrollable carbon powder amount, platinum crucible damage, poor product batch stability, etc., and achieve internal streaks and bubbles. Guaranteed yield and quality, good batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0031] The preparation method of the neutron detection glass scintillator described in the following embodiments 1-4 of the present invention comprises the following steps:

[0032] (1) According to the composition and proportion (%) of the glass scintillator shown in Table 1 respectively, after calculation, select high-purity quartz sand (>99.9%), lithium carbonate, hydrogen as shown in Table 1 with the amount (g) Aluminum oxide, cerium nitrate hexahydrate, and antimony trioxide are used as raw materials, wherein the lithium carbonate is 95% 6 Li 2 CO 3 ; After the above raw materials are fully mixed, they are dried at 120°C for 12 hours to obtain glass batch materials, which are set aside;

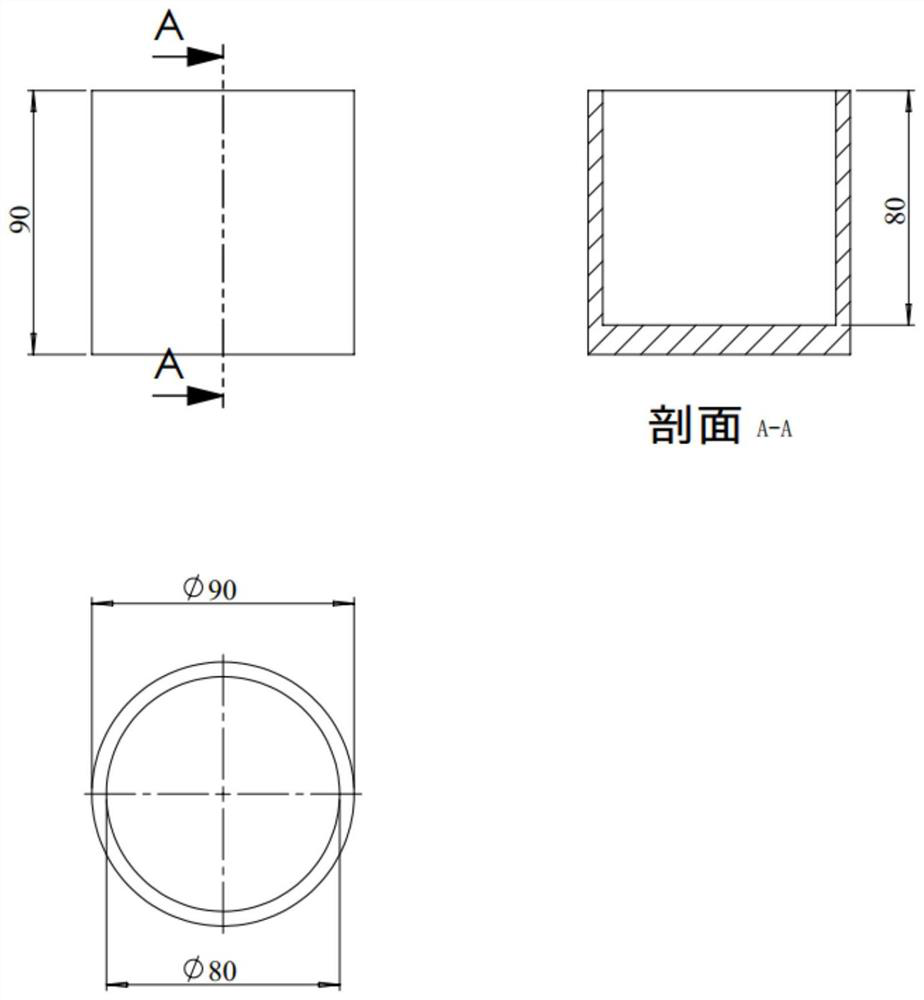

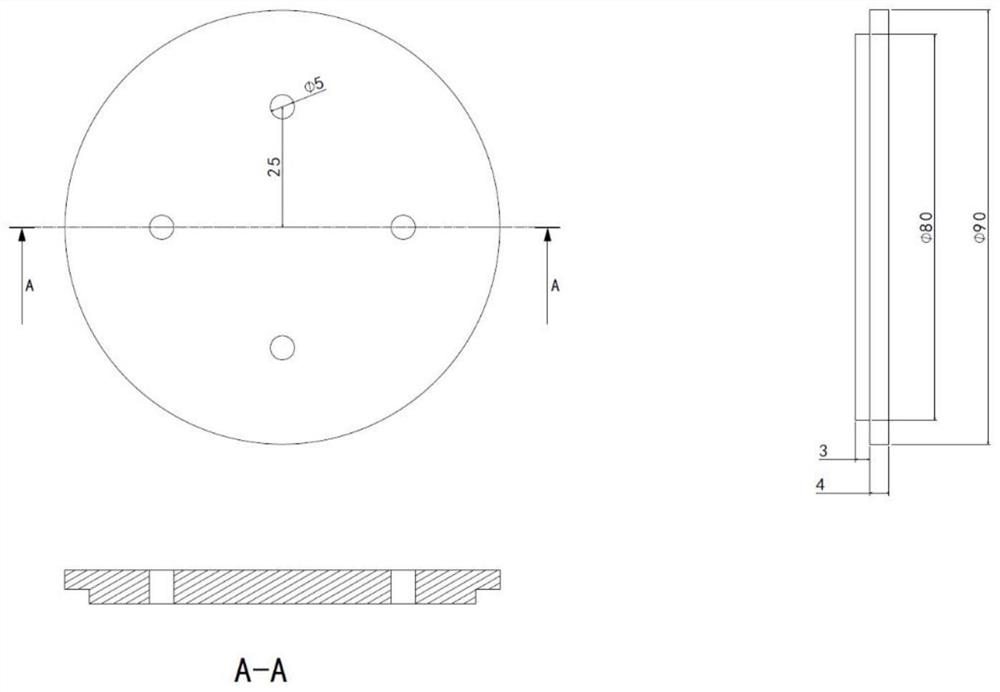

[0033] (2) Put the above-mentioned glass batch material into a closed graphite crucible (the structure and size are as attached Figure 1-2 ), control the graphite purity of the graphite crucible and the graphite crucible cover to be better than 5ppm, place the crucible in a high-temp...

Embodiment 5

[0039] The preparation method of the neutron detection glass scintillator described in this embodiment comprises the following steps:

[0040] (1) According to the composition and proportioning of the neutron detection glass scintillator described in Example 3, high-purity quartz sand (>99.9%), lithium carbonate, aluminum hydroxide, cerium nitrate hexahydrate, and antimony trioxide were used as Raw material, wherein, the lithium carbonate raw material selection abundance is 90% 6 Li 2 CO 3 ; After the above raw materials are fully mixed, they are dried at 120°C for 12 hours to obtain glass batch materials, which are set aside;

[0041] (2) Put the above-mentioned glass batch material into a closed graphite crucible (the structure and size are as attached Figure 1-2 ), control the graphite purity of the graphite crucible and the graphite crucible cover to be better than 20ppm, place the crucible in a high-temperature melting furnace, heat up to 1450°C for high-temperature m...

Embodiment 6

[0044] The preparation method of the neutron detection glass scintillator described in this embodiment comprises the following steps:

[0045] (1) According to the composition and proportioning of the neutron detection glass scintillator described in Example 3, high-purity quartz sand (>99.9%), lithium carbonate, aluminum hydroxide, cerium nitrate hexahydrate, and antimony trioxide were used as Raw material, wherein, described lithium carbonate raw material selects natural Li 2 CO 3 ; After the above raw materials are fully mixed, they are dried at 120°C for 12 hours to obtain glass batch materials, which are set aside;

[0046] (2) Put the above-mentioned glass batch material into a closed graphite crucible (the structure and size are as attached Figure 1-2 ), control the graphite purity of the graphite crucible and the graphite crucible cover to be better than 50ppm, place the crucible in a high-temperature melting furnace, heat up to 1400°C for high-temperature melting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com