Microcapsule type self-repairing sintered epoxy coating and preparation method thereof

A technology of fusion-bonding epoxy and fusion-bonding epoxy powder, which is applied in the direction of microcapsule preparation, microsphere preparation, epoxy resin coating, etc., can solve the problems of high temperature and thermal stability difficult to meet the requirements of sintering and solidification, and achieve good The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

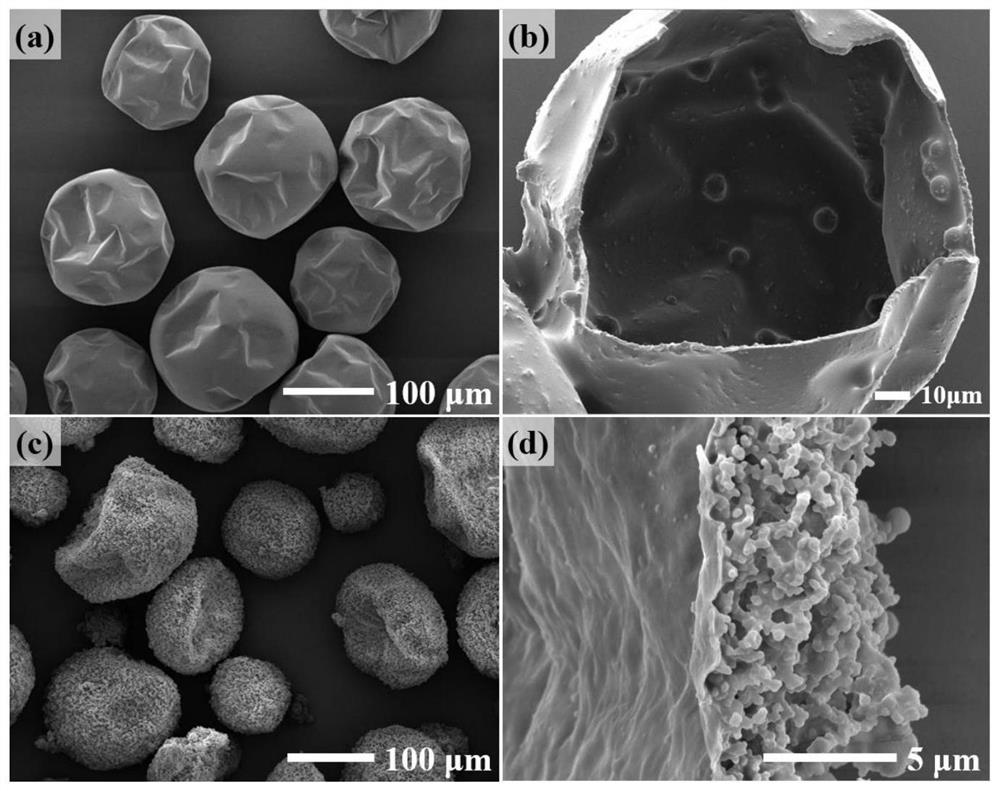

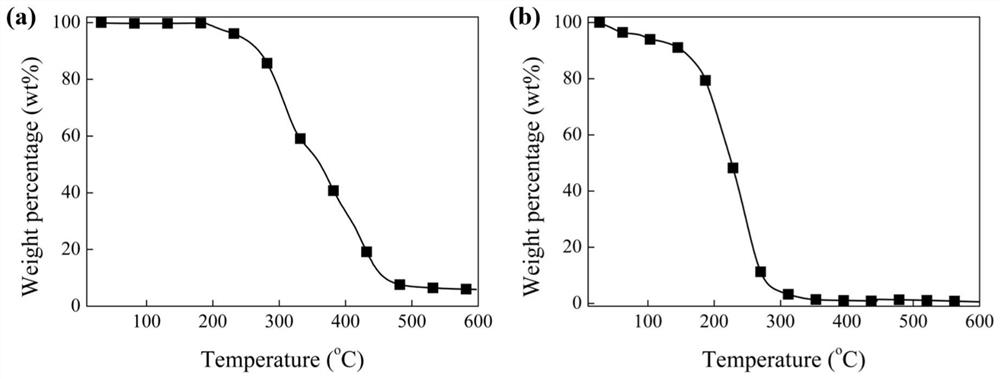

[0046] (1) Mix 90 parts of bisphenol F bisglycidyl ether (BFDGE) with 10 parts of reactive diluent n-butyl glycidyl ether (BGE) to form F10B epoxy resin. Mix 95 parts of the epoxy solution with 5 parts of 4,4-dicyclohexylmethane diisocyanate (HMDI) to form a core solution to be coated. The core liquid was put into a syringe, extruded at a rate of 10.0 mL / h, and atomized under a static voltage of 17 kV to form core liquid micro-droplets. A reaction solution containing 100.0 mL of deionized water, 1.0 g of sodium dodecylsulfonate, and 12.0 g of diethylenetriamine was used to receive the core liquid micro-droplets to form primary microcapsules containing epoxy resin. After the primary microcapsules were prepared, the mixture containing the primary microcapsules and the reaction solution was reacted at 90° C. for 9 hours to form final microcapsules containing epoxy resin. Finally, wash with water, filter, and dry at room temperature to obtain finished epoxy resin microcapsules wi...

Embodiment 2

[0060] The difference with Example 1 is that the core fluid injection rate used in step (1) is 15.0mL / h, and the prepared epoxy resin microcapsule particle diameter is about 150 μm; The injection rate of the core fluid was 1.0mL / h, and the particle size of the prepared amine curing agent microcapsules was about 150 μm.

Embodiment 3

[0062] The difference with Example 1 is that the core liquid injection rate used in step (1) is 5.0mL / h, and the prepared epoxy resin microcapsule particle diameter is about 50 μm; The injection rate of the core fluid was 0.25mL / h, and the particle size of the prepared amine curing agent microcapsules was about 75 μm.

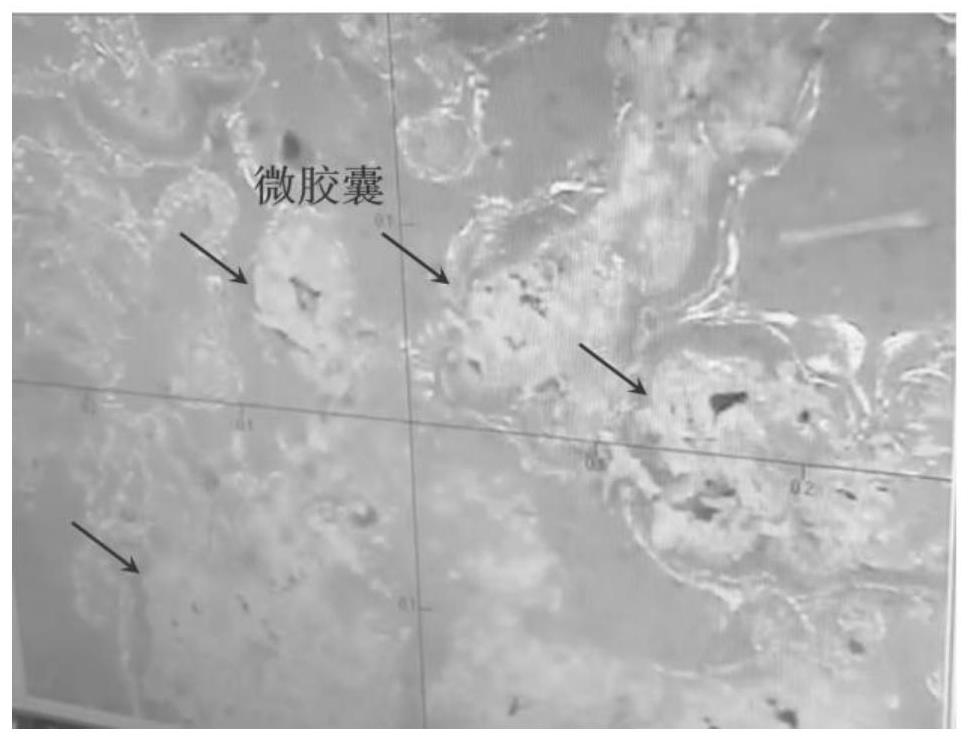

[0063] Figure 6 and Figure 7 The appearances of self-healing fusion-bonded epoxy coatings containing 10.0wt% 50-75μm microcapsules and 10.0wt% 150μm microcapsules were subjected to accelerated corrosion in 10.0wt% saline solution for 2 days. Both exhibit excellent self-healing corrosion protection effects. The results of Examples 1, 2, and 3 show that microcapsules with different particle sizes can be used in the self-repairing anti-corrosion fusion-bonded epoxy coating to realize the self-repairing and anti-corrosion function of the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com