Anaerobic fermentation temperature control system and method based on BP neural network prediction

A technology of BP neural network and temperature control system, applied in the direction of neural learning method, biological neural network model, specific-purpose bioreactor/fermenter, etc., can solve instability, long stable time, time-varying overshoot range Large and other problems, to achieve the effect of improving accuracy and strong time-varying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

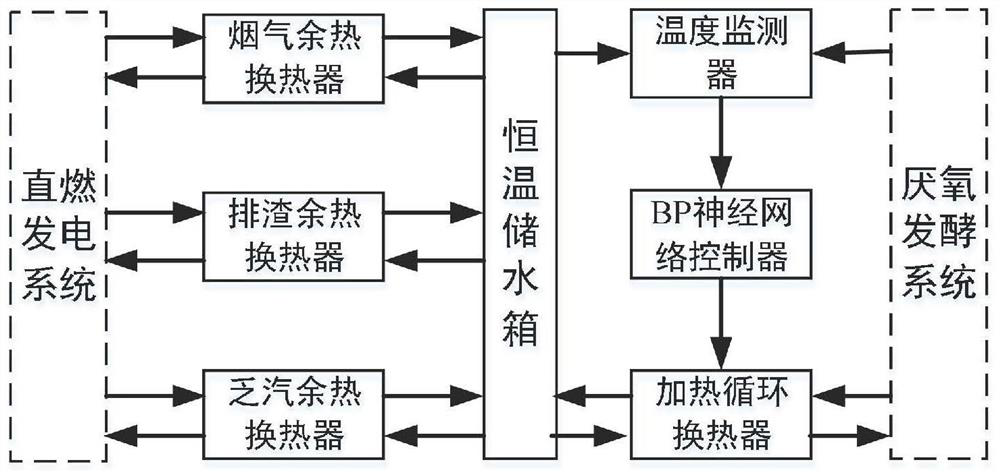

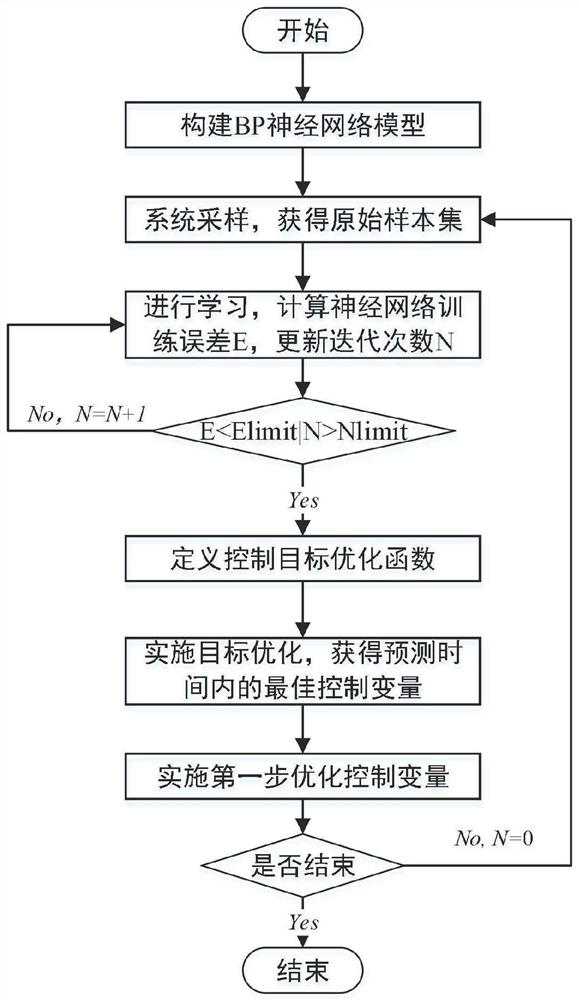

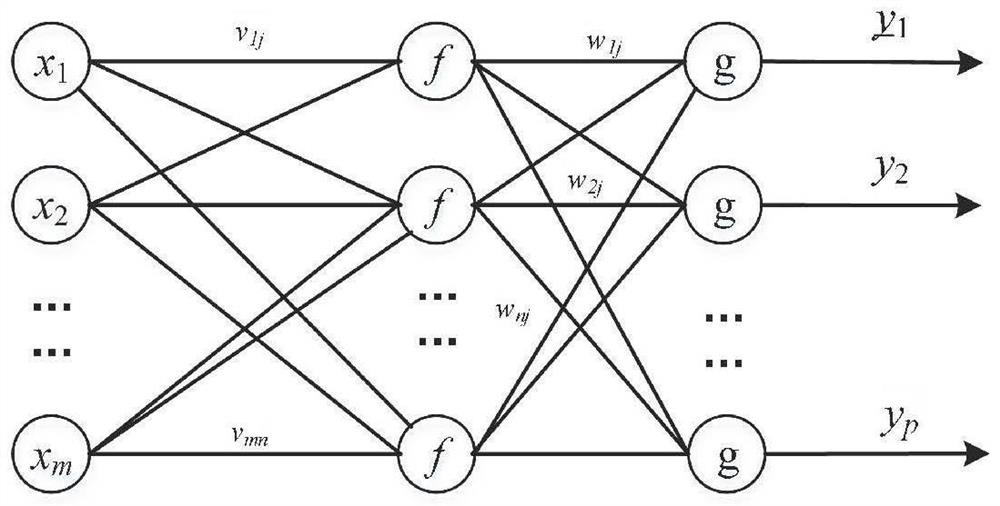

[0044]A temperature control system for anaerobic fermentation based on BP neural network prediction, such as figure 1 As shown, it includes flue gas waste heat exchanger, slagging waste heat exchanger, exhaust steam waste heat exchanger, heating cycle heat exchanger, temperature monitor, constant temperature water storage tank and neural network controller; the flue gas waste heat exchanger The heater is connected with the constant temperature water storage tank, and the waste heat of flue gas from the direct combustion power generation system is recovered to heat the circulating water and sent to the constant temperature water storage tank; The slagging waste heat heating circulating water is sent to the constant temperature water storage tank; the exhaust steam waste heat heat exchanger is connected with the constant temperature water storage tank, and the exhaust steam waste heat heating circulating water of the direct combustion power generation system is recovered and sent...

Embodiment 2

[0068] A temperature control system for anaerobic fermentation based on BP neural network prediction, such as figure 1 As shown, it includes flue gas waste heat exchanger, slagging waste heat exchanger, exhaust steam waste heat exchanger, heating cycle heat exchanger, temperature monitor, constant temperature water storage tank and neural network controller; the flue gas waste heat exchanger The heater is connected with the constant temperature water storage tank, and the waste heat of flue gas from the direct combustion power generation system is recovered to heat the circulating water and sent to the constant temperature water storage tank; The slagging waste heat heating circulating water is sent to the constant temperature water storage tank; the exhaust steam waste heat heat exchanger is connected with the constant temperature water storage tank, and the exhaust steam waste heat heating circulating water of the direct combustion power generation system is recovered and sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com