Bacteriostatic soap added with coconut shell activated carbon powder and preparation method of bacteriostatic soap

A technology of coconut shell activated carbon and antibacterial soap, which is applied in the field of daily chemical cleaning products, can solve the problems of high preparation cost and inconspicuous antibacterial effect, and achieve the effects of improving greasy dullness, reducing skin humidity, and reducing oil output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

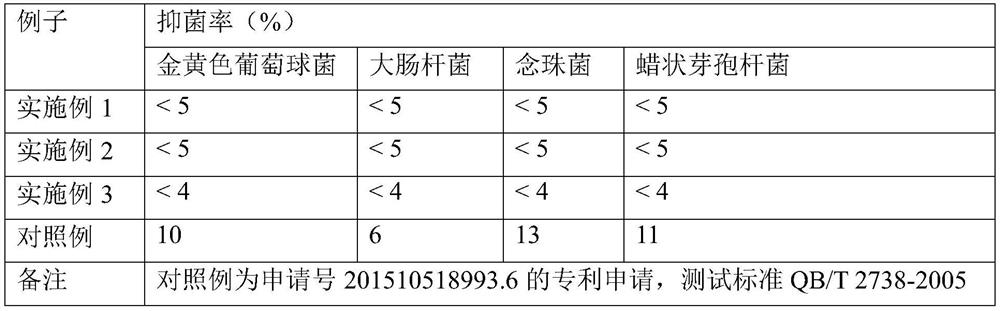

Examples

Embodiment 1

[0033] A bacteriostatic soap added with coconut shell activated carbon powder, prepared from the following raw materials in parts by weight:

[0034] 3 parts of undecylenic acid chloride; 2 parts of coconut shell activated carbon powder; 3100 parts of sorbitol; 1200 parts of propylene glycol; 600 parts of fatty alcohol polyoxyethyl ether sodium sulfate; 1200 parts of stearic acid; 200 parts of palmitic acid; 200 parts of myristic acid ; 200 parts of lauric acid; 200 parts of sodium hydroxide; 120 parts of potassium hydroxide; 70 parts of sodium citrate; 200 parts of sodium lauryl sulfate; 900 parts of glycerol; 1200 parts of sucrose; 1000 parts of deionized water.

[0035] This embodiment also provides a method for preparing a bacteriostatic soap with coconut shell activated carbon powder, which includes the following steps:

[0036] (S1) Raw material mixing: Stearic acid, palmitic acid, myristic acid, lauric acid, fatty alcohol polyoxyethyl ether sodium sulfate, sorbitol and propyle...

Embodiment 2

[0044] A bacteriostatic soap added with coconut shell activated carbon powder, prepared from the following raw materials in parts by weight:

[0045] 6 parts of undecylenic acid chloride; 3 parts of coconut shell activated carbon powder; 3500 parts of sorbitol; 1400 parts of propylene glycol; 800 parts of fatty alcohol polyoxyethyl ether sodium sulfate; 1500 parts of stearic acid; 300 parts of palmitic acid; 300 parts of myristic acid 350 parts of lauric acid; 220 parts of sodium hydroxide; 160 parts of potassium hydroxide; 110 parts of sodium citrate; 300 parts of sodium lauryl sulfate; 1000 parts of glycerol; 1500 parts of sucrose; 1300 parts of deionized water.

[0046] This embodiment also provides a method for preparing a bacteriostatic soap with coconut shell activated carbon powder, which includes the following steps:

[0047] (S1) Raw material mixing: Stearic acid, palmitic acid, myristic acid, lauric acid, fatty alcohol polyoxyethyl ether sodium sulfate, sorbitol and propyle...

Embodiment 3

[0056] A bacteriostatic soap added with coconut shell activated carbon powder, prepared from the following raw materials in parts by weight:

[0057] Undecylenic acid chloride 6 parts; coconut shell activated carbon powder 4 parts; sorbitol 3800 parts; propylene glycol 1700 parts; fatty alcohol polyoxyethyl ether sodium sulfate 1000 parts; stearic acid 1700 parts; palmitic acid 400 parts; myristic acid 400 parts 400 parts of lauric acid; 300 parts of sodium hydroxide; 200 parts of potassium hydroxide; 130 parts of sodium citrate; 400 parts of sodium lauryl sulfate; 1250 parts of glycerol; 1600 parts of sucrose; 1500 parts of deionized water.

[0058] This embodiment also provides a method for preparing a bacteriostatic soap with coconut shell activated carbon powder, which includes the following steps:

[0059] (S1) Raw material mixing: Stearic acid, palmitic acid, myristic acid, lauric acid, fatty alcohol polyoxyethyl ether sodium sulfate, sorbitol and propylene glycol are stirred t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com