Carbon-coated aluminum foil and preparation method thereof

A technology of aluminum foil and carbon coating, applied in the field of lithium ion batteries, can solve the problems of increasing equipment cost, easy falling off of coating, low cost, etc., and achieve the effect of enhancing adhesion strength, improving electrical conductivity and saving raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment relates to a carbon-coated aluminum foil. The carbon layer of the carbon-coated aluminum foil and the aluminum foil are combined in a mechanical interlocking manner. The schematic diagram of the mechanical interlocking structure is shown in figure 1 .

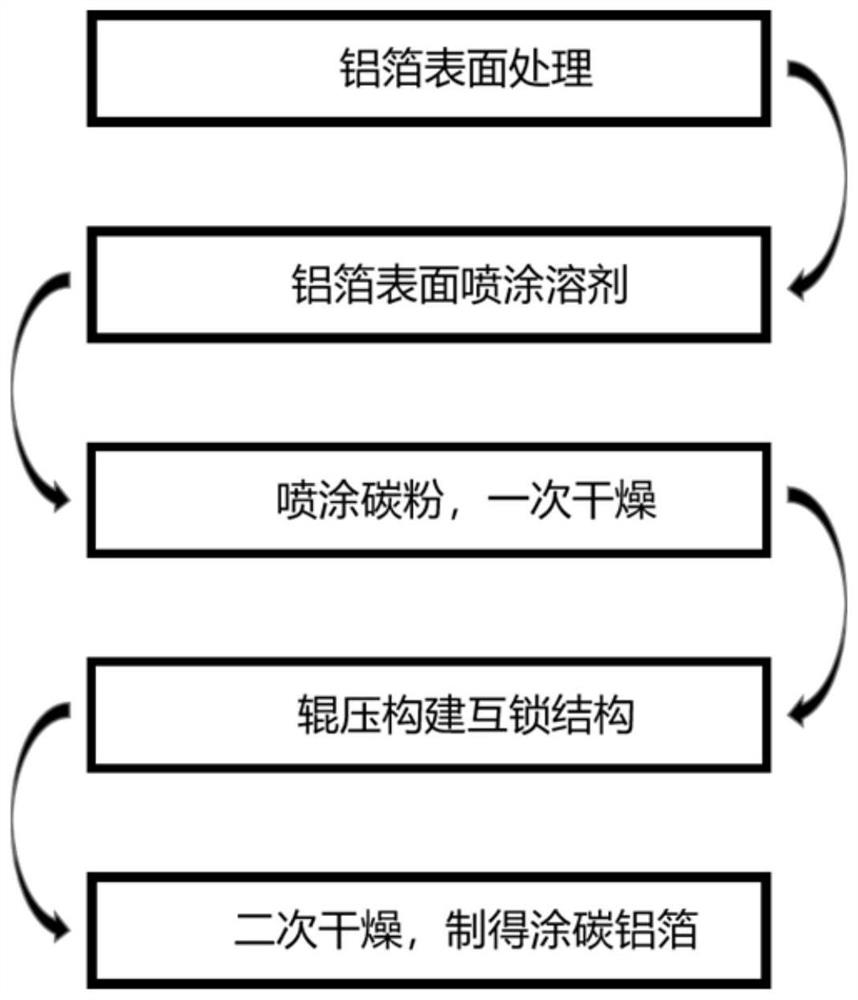

[0032] This embodiment also relates to the preparation method of the aforementioned carbon-coated aluminum foil, such as figure 2 shown, including the following steps:

[0033] Step 1, use carbon dioxide gas to carry aluminum powder, purge and roughen the surface of the aluminum foil, rinse it with deionized water, and dry it for later use;

[0034] Step 2, spray heptane on the surface of the aluminum foil after drying, and the amount of spraying solvent is to spray heptane 10ml per square meter of aluminum foil;

[0035] Step 3, spray acetylene carbon black powder evenly on the surface of aluminum foil coated with heptane, the amount of acetylene carbon black per square meter of aluminum foil is 1g, a...

Embodiment 2

[0039] This embodiment relates to the preparation method of carbon-coated aluminum foil, such as figure 2 shown, including the following steps:

[0040] Step 1, use nitrogen and carbon gas to carry aluminum powder, purge and texture the surface of aluminum foil, rinse it with deionized water, and dry it for later use;

[0041] Step 2, spraying toluene on the surface of the dried aluminum foil, the amount of spraying solvent is to spray 8ml of toluene per square meter of aluminum foil;

[0042] Step 3, evenly spray super carbon black powder on the surface of aluminum foil coated with heptane, the amount of super carbon black per square meter of aluminum foil is 0.6g, and then bake for the first time, the temperature is 80 ℃, and the baking time is 3min;

[0043] Step 4, rolling the baked carbon-coated aluminum foil, the rolling pressure is 30T, and the rolling speed is 15m / min;

[0044] Step 5: Baking for the second time at 100° C. for 10 minutes to obtain a carbon-coated al...

Embodiment 3

[0046] This embodiment relates to the preparation method of carbon-coated aluminum foil, such as figure 2 shown, including the following steps:

[0047] Step 1, use compressed air to carry aluminum powder, purge and roughen the surface of the aluminum foil, rinse it with deionized water, and dry it for later use;

[0048] Step 2, spraying benzene on the surface of the aluminum foil after drying, the amount of spraying solvent is to spray 15ml of benzene per square meter of aluminum foil;

[0049] Step 3, spray carbon nanotubes and natural graphite mixed carbon powder evenly on the surface of aluminum foil coated with benzene, the amount of mixed carbon powder per square meter of aluminum foil is 1.6g, carry out the first baking, the temperature is 50 ℃, bake The time is 3min,;

[0050]Step 4: Carry out rolling treatment on the baked carbon-coated aluminum foil, the rolling pressure is 60T, the rolling speed is 5m / min, step 5, carry out the second baking at 80°C for 5 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com