Method for net forming of aluminum nitride ceramic

A technology of aluminum nitride ceramics and net shaping, applied in the field of aluminum nitride ceramics net shaping, can solve the problems of unsuitable ceramic powder, poisoning, etc., and achieve the effect of solving the problem of toxicity and solving the problem of easy hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

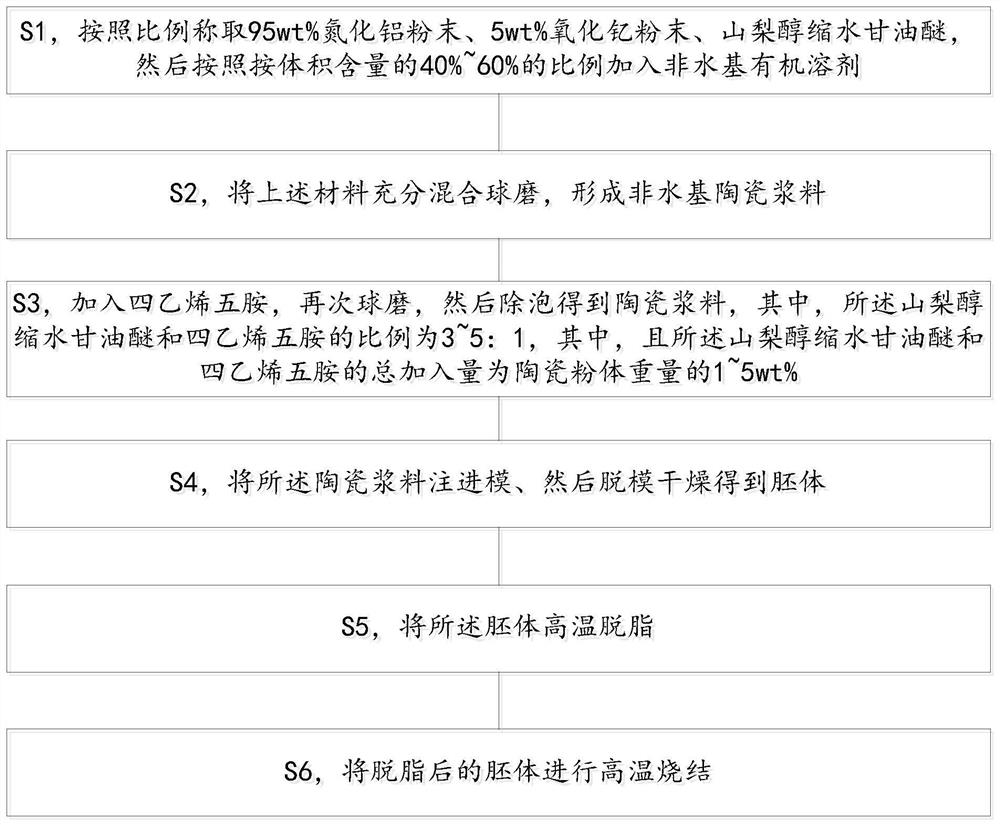

Method used

Image

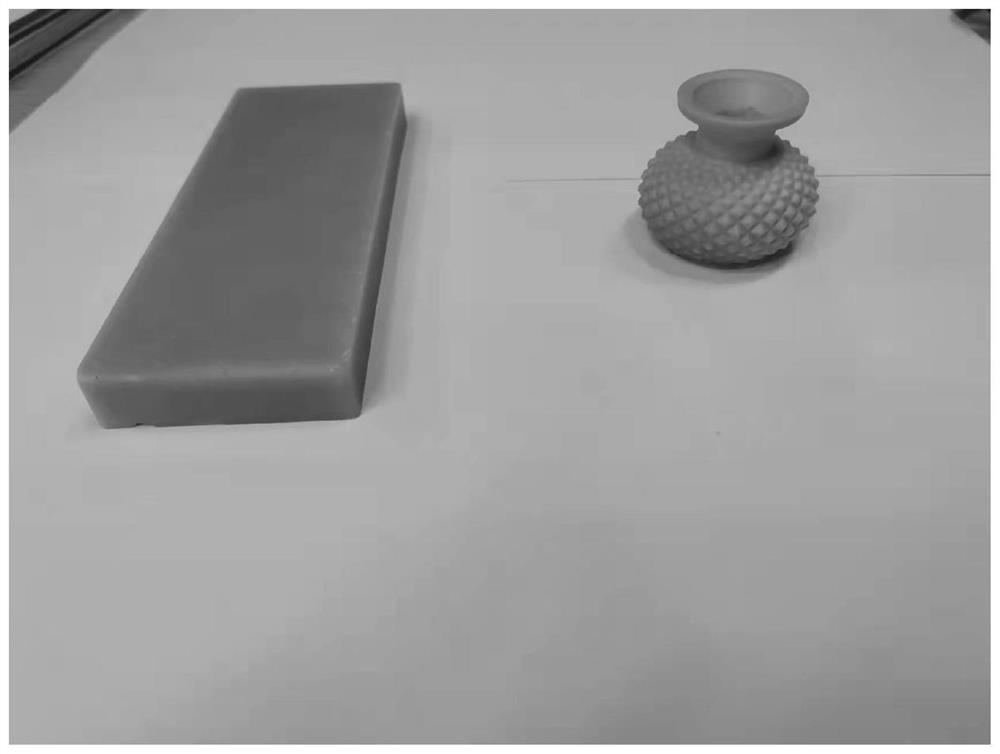

Examples

Embodiment 1

[0039] Mixing: Weigh 285g of aluminum nitride powder, 15g of yttrium oxide powder, 20g of ethanol, 10g of ethylene glycol, 45g of N-methylpyrrolidone, 6g of sorbitol glycidyl ether, and 3g of a commercially available dispersant, and perform ball milling for 8 hours;

[0040] Add cross-linking agent: Add 1.8g of tetraethylenepentamine into the ball mill barrel, continue mixing for 20min, take out the ceramic slurry, and then carry out vacuum stirring to defoam;

[0041] Gel-injection molding: pouring the ceramic slurry into the mold for molding;

[0042] Demoulding and drying: place the ceramic body in an oven, dry at 60°C for 24 hours, and then dry at 100°C for 24 hours.

[0043] Degreasing: Put the dried ceramic body in a degreasing furnace to remove organic matter. The degreasing temperature is 500°C and the time is 3 hours;

[0044] Sintering: put the degreased green body into a sintering furnace for sintering, the sintering temperature is 1800°C, and the time is 3h. Plea...

Embodiment 2

[0046] Mixing: Weigh 285g of aluminum nitride powder, 15g of yttrium oxide powder, 20g of ethanol, 10g of ethylene glycol, 45g of N-methylpyrrolidone, 10g of sorbitol glycidyl ether, and 3g of a commercially available dispersant, and perform ball milling for 8 hours;

[0047] Add cross-linking agent: Add 3g of tetraethylenepentamine into the ball mill barrel, continue mixing for 20min, take out the ceramic slurry, and then carry out vacuum stirring to defoam;

[0048] Gel-injection molding: pouring the ceramic slurry into the mold for molding;

[0049]Demoulding and drying: place the ceramic body in an oven, dry at 60°C for 24 hours, and then dry at 100°C for 24 hours;

[0050] Degreasing: Put the dried ceramic body in a degreasing furnace to remove organic matter. The degreasing temperature is 500°C and the time is 3 hours;

[0051] Sintering: put the degreased green body into a sintering furnace for sintering, the sintering temperature is 1800°C, and the time is 3h. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com