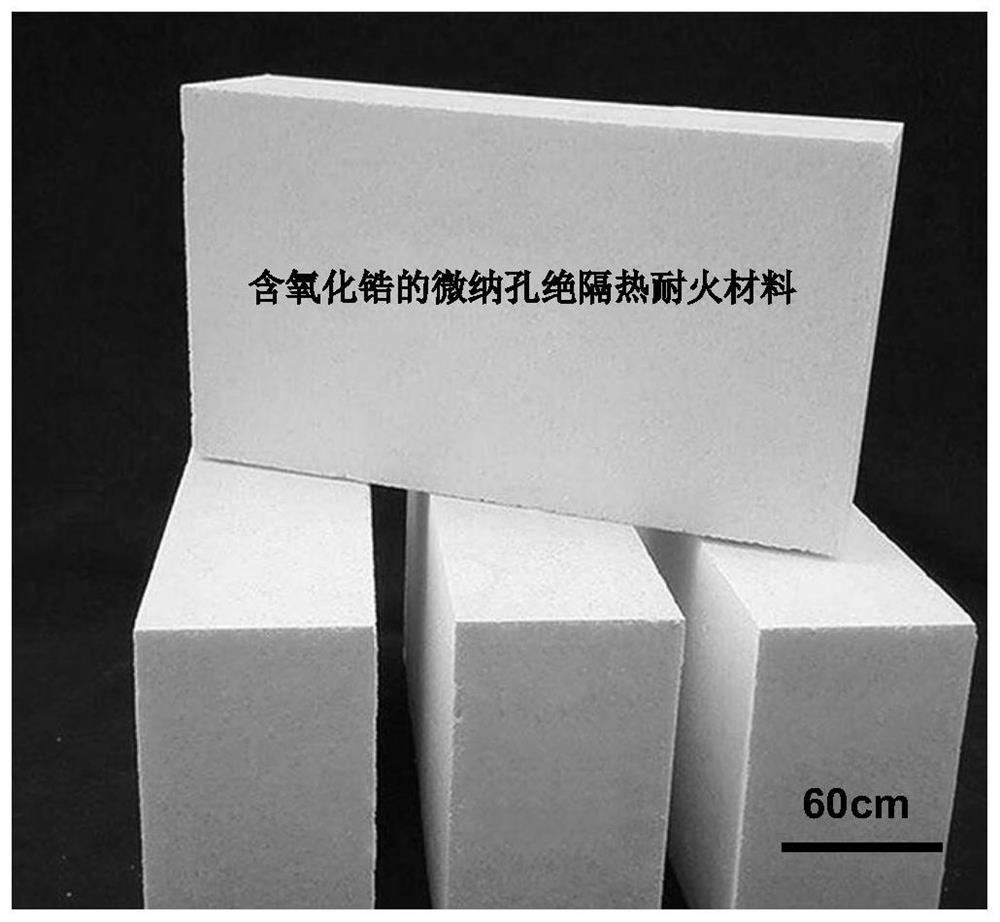

Zirconium oxide-containing micro-nano pore heat insulation refractory material and preparation method thereof

A refractory material containing zirconia technology, which is applied in the field of refractory materials, can solve the problems of thermal insulation refractory materials, low thermal conductivity of materials, and low bulk density, etc., and achieves short demoulding and drying cycles, high strength, and simple process easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

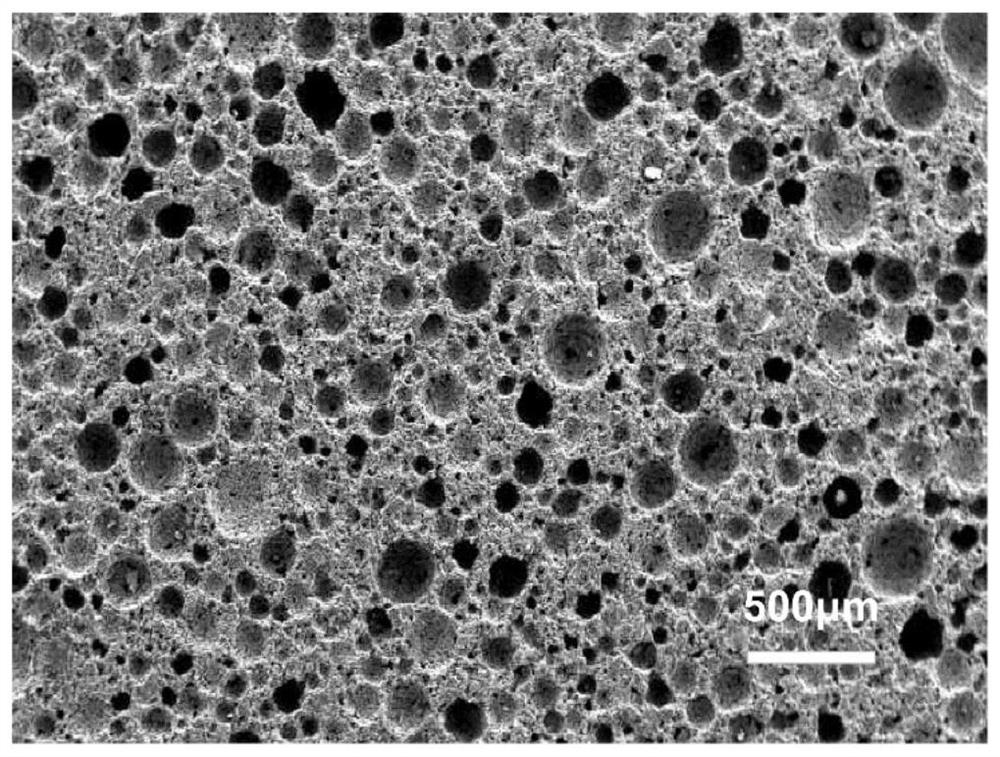

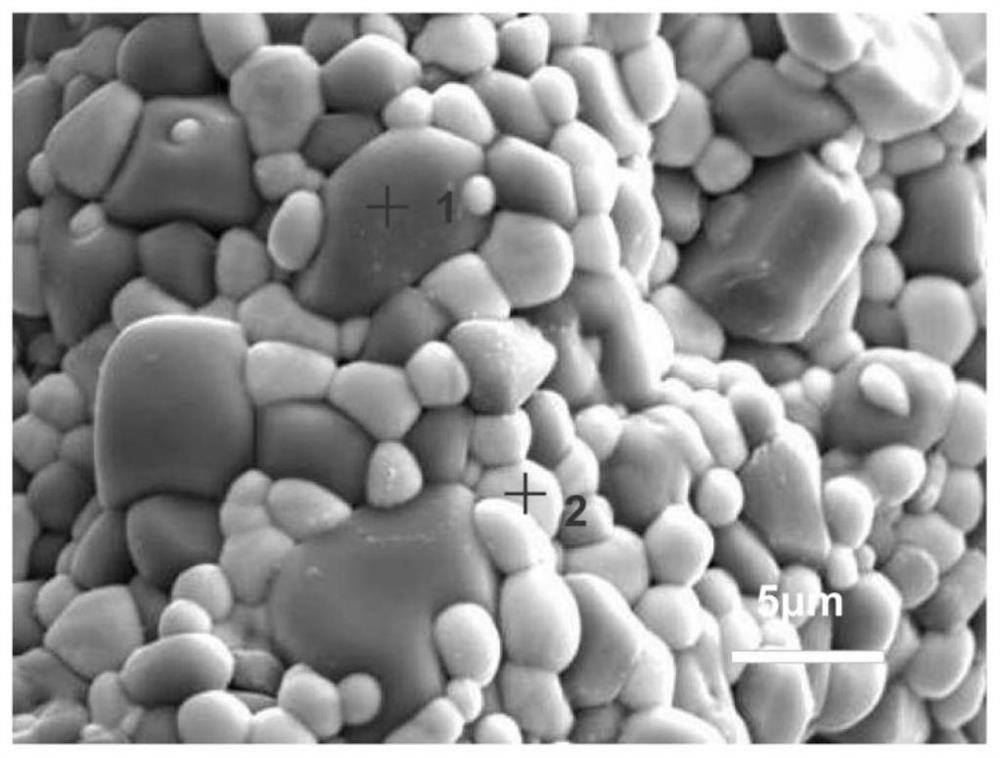

[0101] The micro-nanoporous heat-insulating refractory material containing zirconia in this embodiment is composed of basic raw materials, suspending agent, mineralizer, infrared sunscreen agent, foaming agent, inorganic curing agent, organic curing agent, cell regulator and water production. The kind and consumption description of each raw material in the present embodiment are as follows:

[0102] Basic raw materials: 0.4 tons of zircon, 0.1 tons of industrial Al(OH) 3 , 0.1 tons of boehmite, 0.3 tons of kaolin, 0.1 tons of silica powder. The chemical composition of zircon is ZrO 2 The mass percentage of SiO is 64~67wt%. 2 The mass percentage content of 32 ~ 35wt%, particle size ≦ 0.08mm; industrial Al(OH) 3 Al in the chemical composition 2 o 3 The mass percentage of boehmite ≧ 65wt%, particle size ≦ 0.08mm; Al in the chemical composition of boehmite 2 o 3 Mass percentage ≧70%, particle size ≦0.08mm; Al in the chemical composition of kaolin 2 o 3 The mass percentag...

Embodiment 2~17

[0118] The formula composition of the zirconia-containing micro-nanoporous heat-insulating refractory materials in Examples 2-17 is shown in Table 1 and Table 2 below:

[0119] Table 1 Example 2-9 Formulas of micro-nanoporous insulating refractory materials containing zirconia

[0120]

[0121]

[0122]

[0123]

[0124]

[0125] Table 2 Example 10-17 Formula of micro-nanoporous thermal insulation refractory material containing zirconia

[0126]

[0127]

[0128]

[0129]

Embodiment 2

[0130] The preparation process of the micro-nanoporous insulating refractory material containing zirconia in Example 2 is as follows:

[0131] (1) Weigh zircon, industrial alumina, β-Al according to the formula 2 o 3 , γ-Al 2 o 3 , coal gangue, diatomite, β-tridymite, poured into a planetary mixer and dry-mixed for 5 minutes to obtain basic raw materials; weighed bentonite, polyaluminum chloride, Y 2 o 3 , MgO, V 2 o 5 , NiO, K 2 Ti 6 o 13 , Sb 2 o 5 , poured into a double-cone mixer and dry-mixed for 5 minutes to obtain the additive.

[0132] (2) Weigh quaternary ammonium type Gemini surfactant, animal protein foaming agent, silica gel, vinyl acetate, ethylene and acrylate copolymer, hydroxyethyl cellulose ether, hydroxyethyl ethyl cellulose Ether and hydroxypropyl cellulose ether were poured into a V-type mixer and mixed for 5 minutes to obtain a uniform foaming composition.

[0133] (3) Pour the basic raw materials and additives obtained in step (1) into a roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com