Novel efficient chelate antioxidant as well as preparation method and application thereof

A chelate and antioxidant technology, applied in the field of new and efficient chelate antioxidants and their preparation, can solve the problems of unsatisfactory compatibility, stable efficiency and cost, easy precipitation and loss, and single mechanism and other problems, to achieve high-efficiency anti-aging effect, not easy to migrate, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

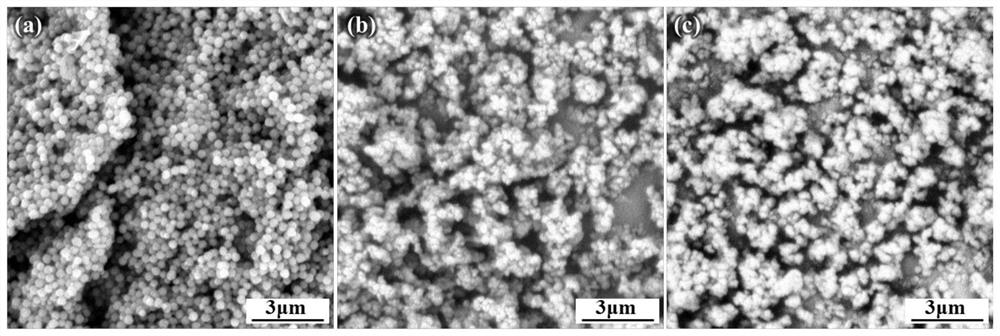

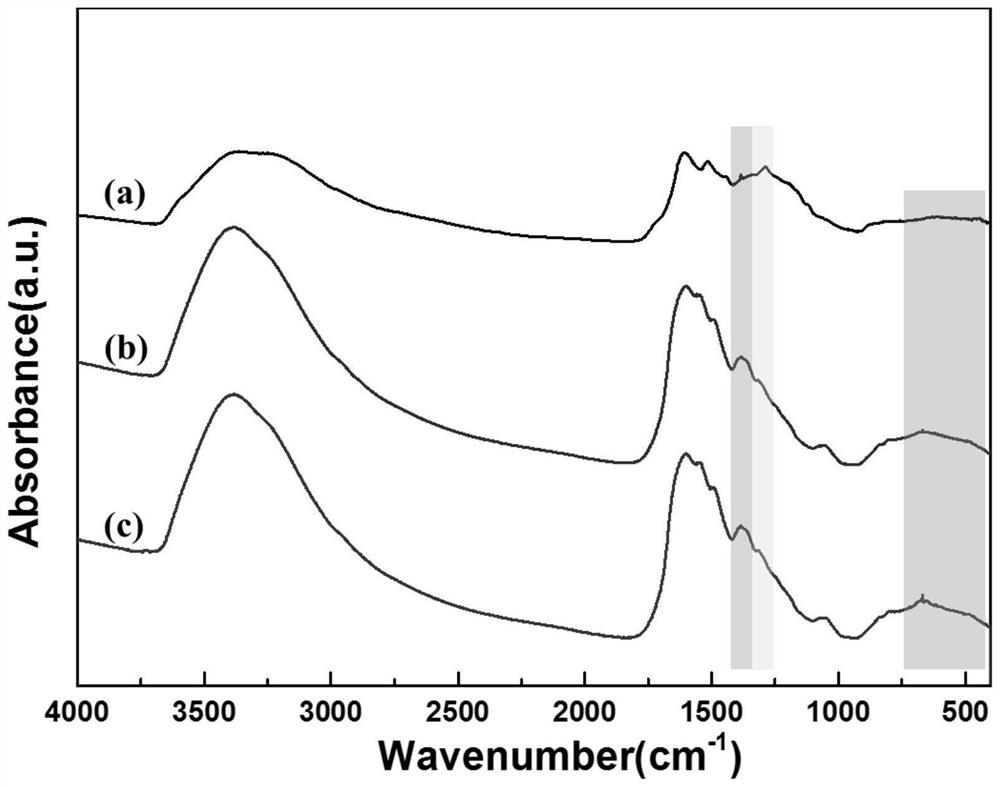

[0035] Preparation of polydopamine chelate:

[0036] Add 9.09 g of tris to 1500 ml of deionized water at a temperature of 60°C, stir and dissolve, then adjust the pH to 8.5 by adding hydrochloric acid dropwise to obtain a tris buffer with a pH of 8.5, and then Add 1.5g of dopamine hydrochloride, stir and dissolve, and after the dopamine hydrochloride is completely dissolved, a polydopamine solution is obtained;

[0037] Add 4.15 g of nickel sulfate hexahydrate into the polydopamine solution, keep the temperature at 60°C, and stir for 12 hours. After the reaction was completed, a mixed solution was obtained;

[0038] The mixed solution was subjected to suction filtration, and the precipitate obtained by suction filtration was dispersed in 1500mL distilled water for cleaning, and then suction filtration was performed again, and the cleaning and suction filtration process was repeated 3 times to obtain a black solid product, ensuring that the unreacted dopamine monomer and othe...

Embodiment 2

[0042] Preparation of polydopamine chelate:

[0043] Add 9.09 g of tris to 1500 ml of deionized water at a temperature of 60°C, stir and dissolve, then adjust the pH to 8.5 by adding hydrochloric acid dropwise to obtain a tris buffer with a pH of 8.5, and then Add 1.5g of dopamine hydrochloride, stir and dissolve, and after the dopamine hydrochloride is completely dissolved, a polydopamine solution is obtained;

[0044] Add 2.075 g of nickel sulfate hexahydrate into the polydopamine solution, keep the temperature at 70°C, and stir for 8 hours. After the reaction was completed, a mixed solution was obtained;

[0045] The mixed solution was subjected to suction filtration, and the precipitate obtained by suction filtration was dispersed in 1500mL distilled water for cleaning, and then suction filtration was performed again, and the cleaning and suction filtration process was repeated 3 times to obtain a black solid product, ensuring that the unreacted dopamine monomer and othe...

Embodiment 3

[0049] Preparation of polydopamine:

[0050] Add 9.09g of Tris to 1500ml of deionized water at 60°C, stir to dissolve, adjust the pH to 8.5 by adding hydrochloric acid dropwise, add 1.5g of dopamine hydrochloride, keep the temperature at 60°C, and stir for 12 hours. After the reaction was completed, the reaction solution was subjected to suction filtration, and then the black solid obtained by suction filtration was redispersed in 1500 mL of distilled water, and suction filtration was performed again. This process was repeated 3 times to ensure that unreacted dopamine monomer and other impurities were washed away. Finally, the washed black solid was dried in a vacuum oven at 60° C. for 24 hours to obtain the final product polydopamine.

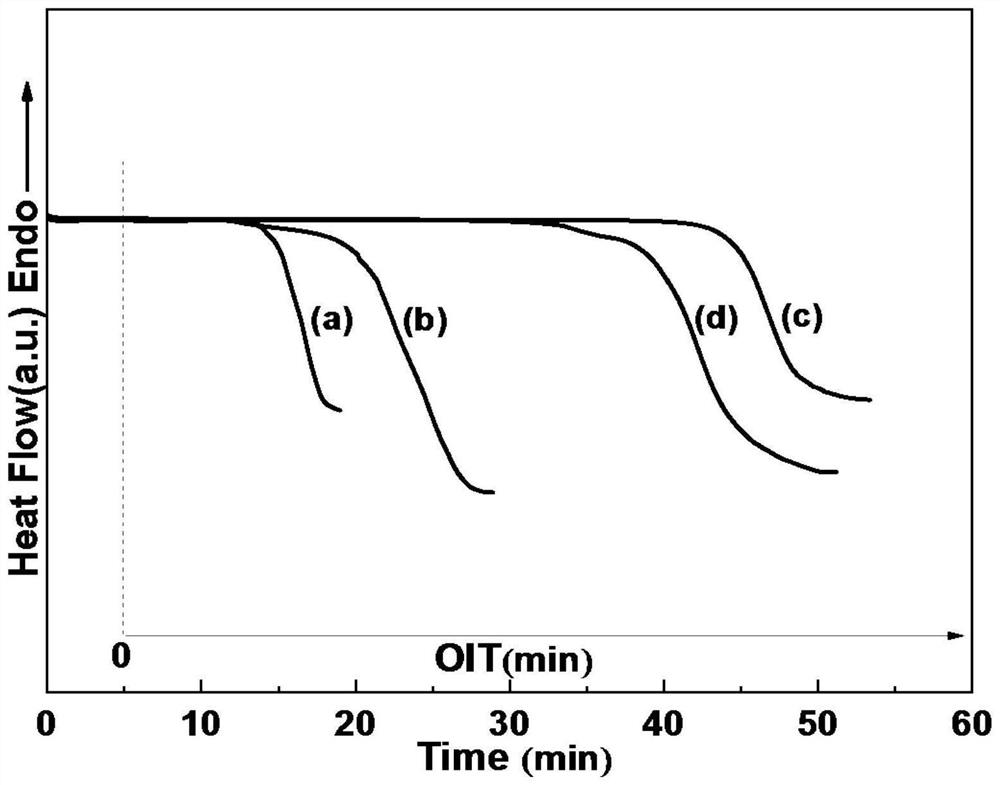

[0051] Application of polydopamine in polypropylene:

[0052] 38 g of polypropylene and 190 mg of polydopamine were melt-blended at 50 rpm and 180° C. for 10 min with an internal mixer to prepare a polypropylene / polydopamine composite materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com