Application of programmable immunocompetence carbon fiber-molybdenum disulfide composite material in preparation of wound healing medicine

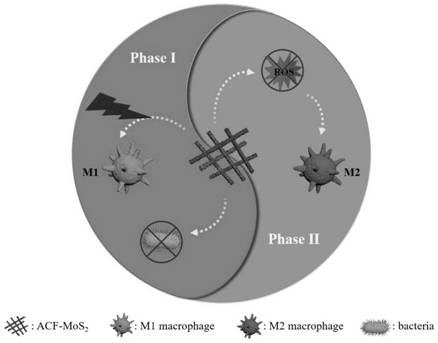

A composite material and wound healing technology, applied in the direction of molybdenum sulfide, carbon fiber, drug combination, etc., can solve the problems of not being able to achieve the optimal treatment effect, accelerate wound healing, etc., and achieve the effect of promoting wound healing and accelerating wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1MoS 2 Preparation of Nanomaterials

[0026] First use an analytical balance to weigh 150 mg (NH 4 ) 2 MoS 4 Dissolved into 30 mL of pure water by strong magnetic stirring (500 rpm) to obtain a homogeneous solution, then the solution was transferred to a 50 mL polyphenylene-lined stainless steel autoclave and kept at 220 °C for 12 h. Finally, the obtained black product (MoS 2 nanomaterials) were washed three times with ethanol and deionized water respectively and redispersed in pure aqueous solution for further use.

Embodiment 2

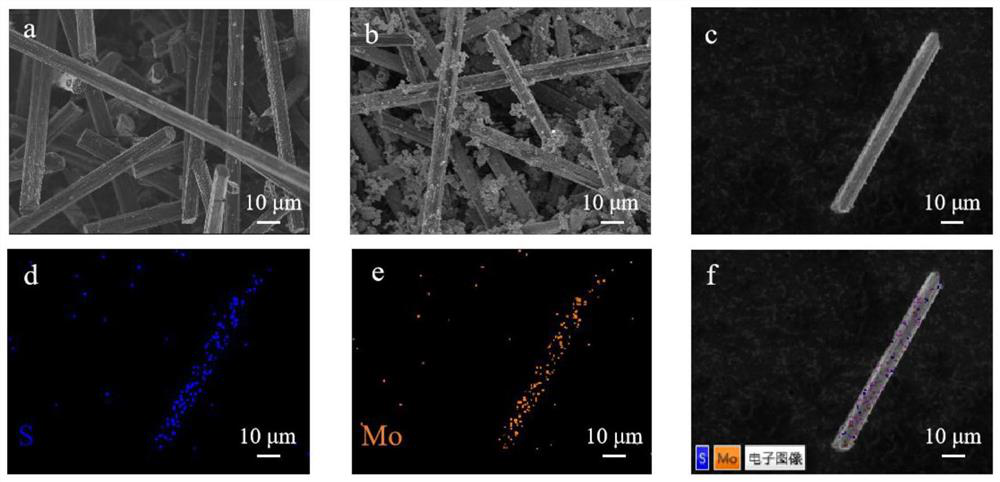

[0027] Example 2ACF-MoS 2 Preparation of composite materials

[0028] First, the carbon fiber (CF) was refluxed in acetone solution for 10 h, then soaked in concentrated nitric acid for about 4 h, and washed with pure water until neutral to obtain activated carbon fiber (ACF). Using N,N-dimethylformamide (DMF) as solvent and reducing agent, (NH 4 ) 2 MoS 4 MoS on ACF as precursors of molybdenum and sulfur 2 Functional. Concrete steps include: take 300mg ACF and 150mg (NH 4 ) 2 MoS 4 Put them together in a mixture of 15 mL DMF and 15 mL pure water to obtain a homogeneous solution, then transfer the solution into a 50 mL polyphenylene-lined stainless steel autoclave and keep at 220 °C for 12 h. Finally, the obtained black product (ACF-MoS 2 composites) were washed three times with ethanol and deionized water respectively and redispersed in pure aqueous solution for further use. ACF-MoS obtained by inductively coupled plasma emission spectrometer (ICP) test 2 The conte...

Embodiment 3

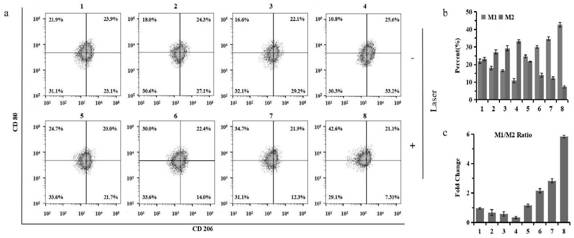

[0030] Example 3 Study of ACF-MoS 2 Effect of Composite Materials on Macrophage Polarization

[0031] RAW264.7 cells (mouse mononuclear macrophage leukemia cells) were plated in 6-well plates and cultured for 24 hours, and then treated with equal amounts of different materials (Control, ACF, MoS 2 , ACF-MoS 2 ) to treat cells and perform NIR (0.75W / cm 2) light treatment. After continuing to culture for 6 h, the cells were washed twice with PBS, and the cells were lysed and centrifuged down (1000 rpm, 6 min). Raw 264.7 cells induced by different conditions were collected, and the expressions of surface marker antigens CD80 (M1 macrophage marker) and CD206 (M2 macrophage marker) in each group were detected by flow cytometry.

[0032] figure 2 for ACF-MoS 2 Effect diagram of the composite material on the polarization of macrophages, where (a-c) respectively represent: (a): Each group (1: Control; 2: ACF; 3: Mo S 2 ;4:ACF-MoS 2 ;5:Control+Laser;6:ACF+Laser;7:MoS 2 +Laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com