Photocatalytic MXene composite membrane and preparation method thereof

A composite membrane, photocatalysis technology, applied in chemical instruments and methods, special compound water treatment, membranes, etc., can solve the problems of reduced specific surface area, weakened catalytic effect, and needs to be studied, so as to reduce the cost of water treatment and achieve good self-cleaning. ability, the effect of alleviating membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of photocatalytic MXene composite film, comprising:

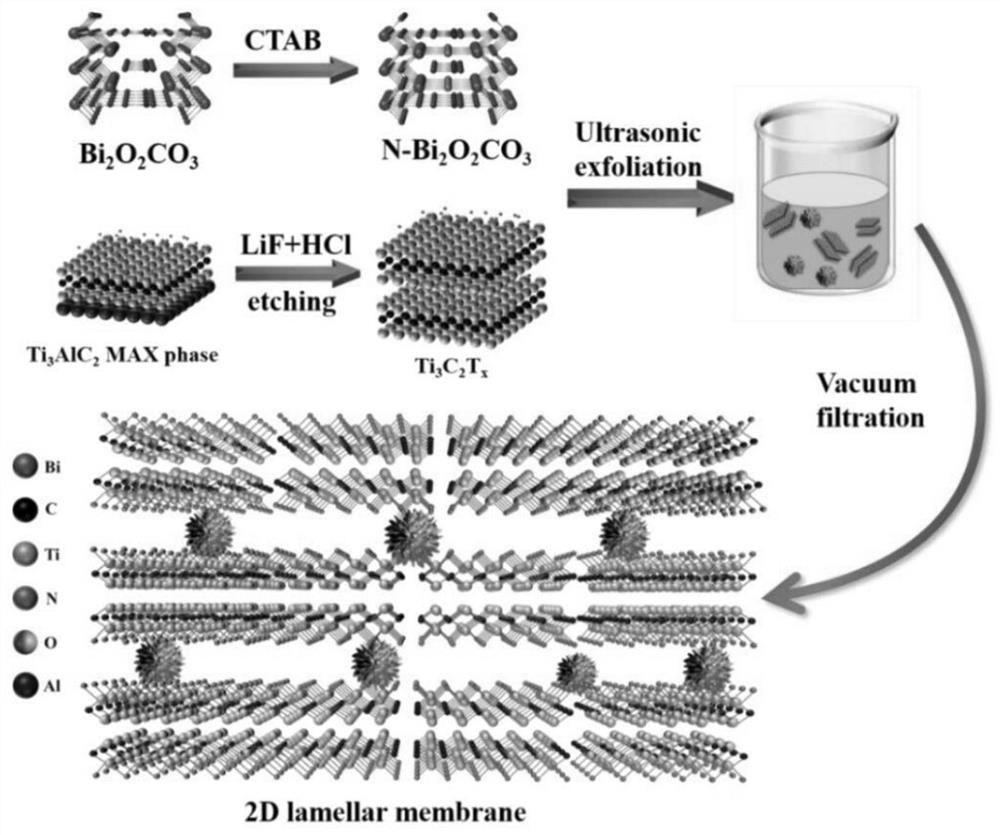

[0044] (1) Preparation of MXene: use LiF+HCl mixed reagent to etch the MAX phase, and ultrasonic-assisted exfoliation to prepare MXene two-dimensional materials, specifically:

[0045] ①Dissolve 0.5g LiF in 15mL HCl solution, and 0.5g Ti 3 AlC 2 The powder was added to the solution, stirred magnetically at 30°C for 20 h, and then washed several times with deionized water (DI) until the pH of the supernatant of the solution was 6;

[0046] ② After several times of centrifugation at 3500rpm, the supernatant was collected to obtain multilayer Ti 3 C 2 T X Nanosheets: After the supernatant was sonicated in 200 mL deionized water for 6 h, the dispersion was centrifuged for 30 min, and the monolayer MXene nanosheets were collected and freeze-dried for storage.

[0047] (2) Bi 2 o 2 CO 3 Preparation of Bi by low-temperature chemical method 2 o 2 CO 3 (BOC) nanoparticles, specifically:

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com