Preparation method and application of monolithic catalyst for treating CVOC

A monolithic catalyst and pretreatment technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of low light-off temperature, treatment efficiency, influence on elimination effect, catalyst poisoning, etc., and achieve the promotion of catalysis The effects of activity, high specific surface area, and good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

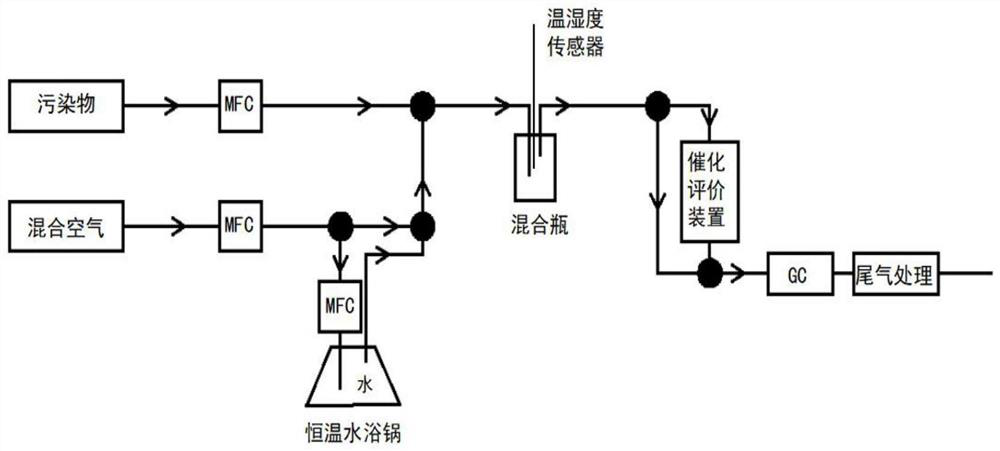

Method used

Image

Examples

Embodiment 1

[0035] 1) The commercially available cordierite honeycomb ceramic material was cut into cubic samples with a size of 15mm×15mm×15mm, washed with distilled water, pretreated with 15% nitric acid solution at 80°C for 5 hours, and then the carrier Wash with distilled water, dry in an oven at 100°C for 4h and cool to room temperature.

[0036] 2) Using zeolite molecular sieve as the second carrier layer, add morpholine, AI 2 o 3 , SiO 2 ,P 2 o 5 and deionized water, the molar ratio is 3:1:0.25:1:60 and step 1) pretreated cordierite honeycomb ceramic carrier, reacted at 200°C for 48h, cooled to room temperature, dried at 100°C for 4h, cooled The sample was calcined at 700° C. for 5 h at a heating rate of 5° C. / min, and cooled to room temperature to obtain a sample with a second support layer, wherein the loading of the second support layer was 20%.

[0037] 3) Take analytically pure grade tetrabutyl titanate and move it into the polytetrafluoroethylene liner of the autoclave, ...

Embodiment 2

[0041] 1) The commercially available cordierite honeycomb ceramic material was cut into cubic samples with a size of 15mm×15mm×15mm, washed with distilled water, pretreated with 15% nitric acid solution at 80°C for 5 hours, and then the carrier Wash with distilled water, dry in an oven at 100°C for 4h and cool to room temperature.

[0042] 2) Using zeolite molecular sieve as the second carrier layer, add morpholine, AI 2 o 3 , SiO 2 ,P 2 o 5 , the molar ratio is 3:1:0.38:1:60 and step 1) pretreated cordierite honeycomb ceramic carrier, reacted at 200°C for 48h, cooled to room temperature, dried at 100°C for 4h, and cooled the sample at 5°C Calcination at a heating rate of 700° C. for 5 h at a heating rate of 1 / min, and cooling to room temperature to obtain a sample with a second support layer, wherein the loading of the second support layer is 20%.

[0043] 3) Take analytically pure grade tetrabutyl titanate and move it into the polytetrafluoroethylene liner of the autocl...

Embodiment 3

[0047] 1) The commercially available cordierite honeycomb ceramic material was cut into cubic samples with a size of 15mm×15mm×15mm, washed with distilled water, pretreated with 15% nitric acid solution at 80°C for 5 hours, and then the carrier Wash with distilled water, dry in an oven at 100°C for 4h and cool to room temperature.

[0048] 2) Using zeolite molecular sieve as the second carrier layer, add morpholine, AI 2 o 3 , SiO 2 ,P 2 o 5 and deionized water, the molar ratio is 3:1:0.6:1:60 and step 1) pretreated cordierite honeycomb ceramic carrier, reacted at 200°C for 48h, cooled to room temperature, dried at 100°C for 4h, cooled The sample was calcined at 700° C. for 5 h at a heating rate of 5° C. / min, and cooled to room temperature to obtain a sample with a second support layer, wherein the loading of the second support layer was 20%.

[0049] 3) Take analytically pure grade tetrabutyl titanate and move it into the polytetrafluoroethylene liner of the autoclave, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com