Thickening agent, composition forming same, emulsion polymer, fracturing fluid system and application thereof

A technology of thickening agent and composition, which is applied in the direction of drilling composition, chemical instruments and methods, and can solve the problem of less residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Preferably, the preparation method of the thickener comprises: acrylamide, N,N-dimethylacrylamide, sodium acrylate, cationic polymerizable surfactant, viscoelastic surfactant, initiator, optional inorganic salt, Optional organic salts, optional co-solvents, and optional heat stabilizers are prepared according to a predetermined ratio; after mixing the raw materials evenly, the temperature is controlled within the range of 5°C to 50°C, and nitrogen gas is introduced for 30 minutes to remove oxygen in the reaction solution , adding an initiator, the temperature for initiating the polymerization reaction is 5°C to 50°C, and after the end of the polymerization reaction, continue to keep warm for 2 to 4 hours to obtain rubber blocks; chemical powder products.

[0048] Another aspect of the present application also provides a thickener, which is prepared from the composition for forming the thickener provided in the present application as a raw material by polymerization unde...

Embodiment 1

[0063] Based on 100 parts by weight, the raw materials for the preparation of the thickener include: 20 parts of acrylamide, 20 parts of N,N-dimethylacrylamide, 30 parts of sodium acrylate, 8 parts of p-bromostyrene octadecyldimethyl tertiary Amine quaternary ammonium salt, 3 parts cis-13-docenoamidopropyl dimethyl hydroxypropyl sulfobetaine, 0.5 part initiator (azobisisobutylamidine hydrochloride), 1.5 parts organic salt (sodium salicylate), 5 parts of inorganic salt (potassium chloride), and the balance is water.

[0064] Wherein, the preparation steps of cationic surfactant are as follows:

[0065] Add 80.0g of octadecyldimethyl tertiary amine into a single-necked flask, add 100.0mL of absolute ethanol to dissolve, raise the temperature to 50°C, slowly add 40.0g of p-bromostyrene, react for 10h, and distill under reduced pressure to obtain a light yellow viscous The product was put into a vacuum drying oven at 60°C and vacuum-dried to obtain a white solid product with a mo...

Embodiment 2

[0071] The difference from Example 1 is: based on 100 parts by weight, the raw materials for the preparation of the thickener include: 10 parts of acrylamide, 20 parts of N,N-dimethylacrylamide, 15 parts of sodium acrylate, 15 parts of long carbon chain tertiary Amine quaternary ammonium salt polymerizable surfactant, 0.2 part of viscoelastic surfactant, 0.01 part of initiator, and the balance is water. The molecular weight of the thickener is 8 million.

[0072] Adopt the method identical with embodiment 1 to make emulsion polymer, be recorded as sample 2.

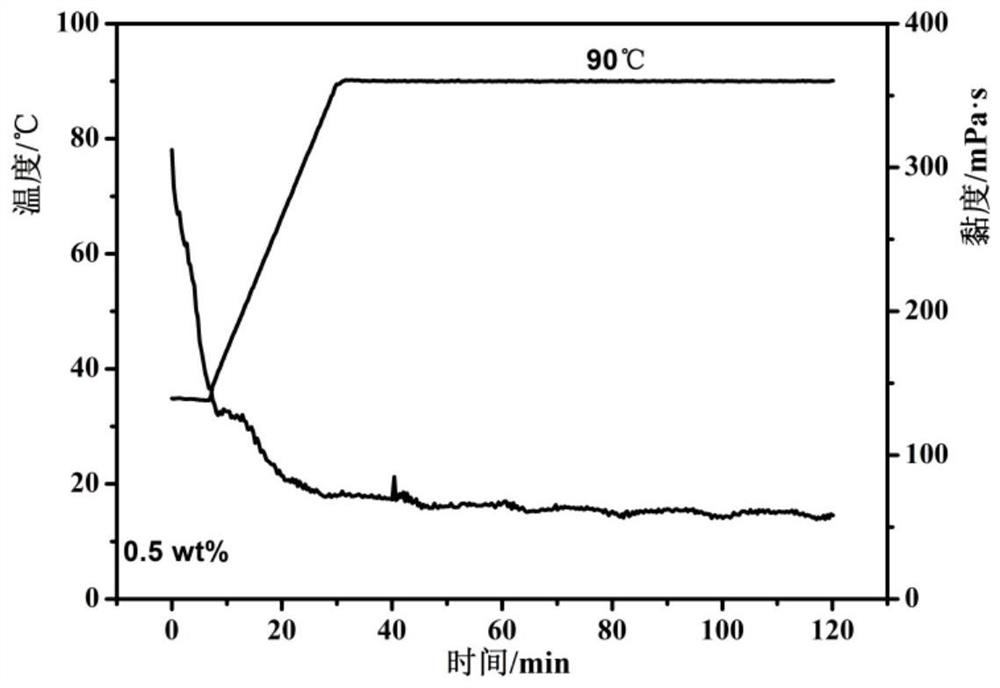

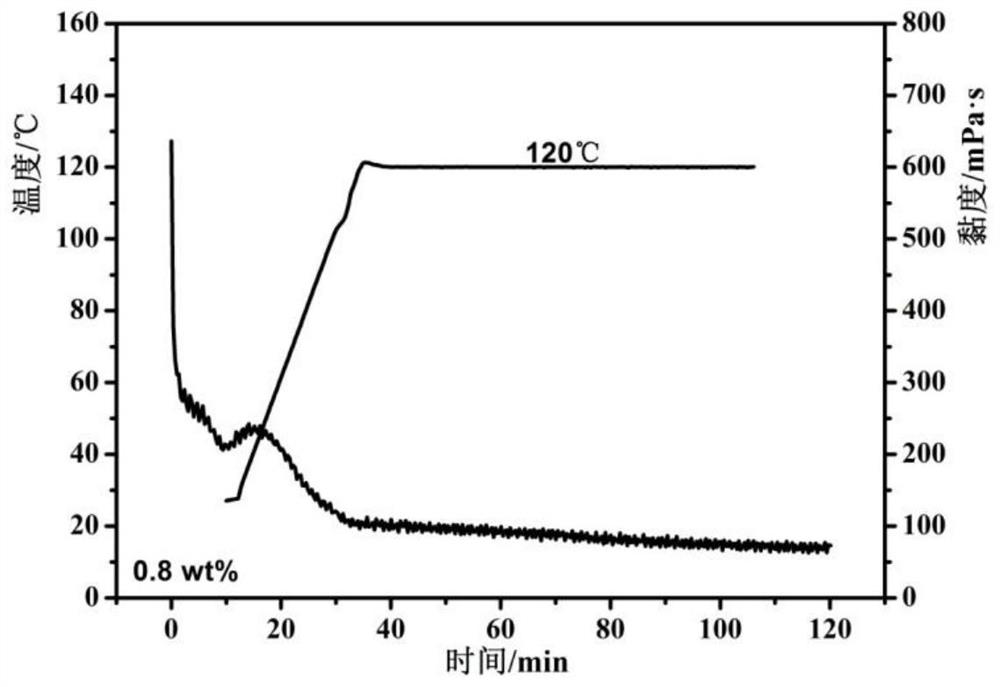

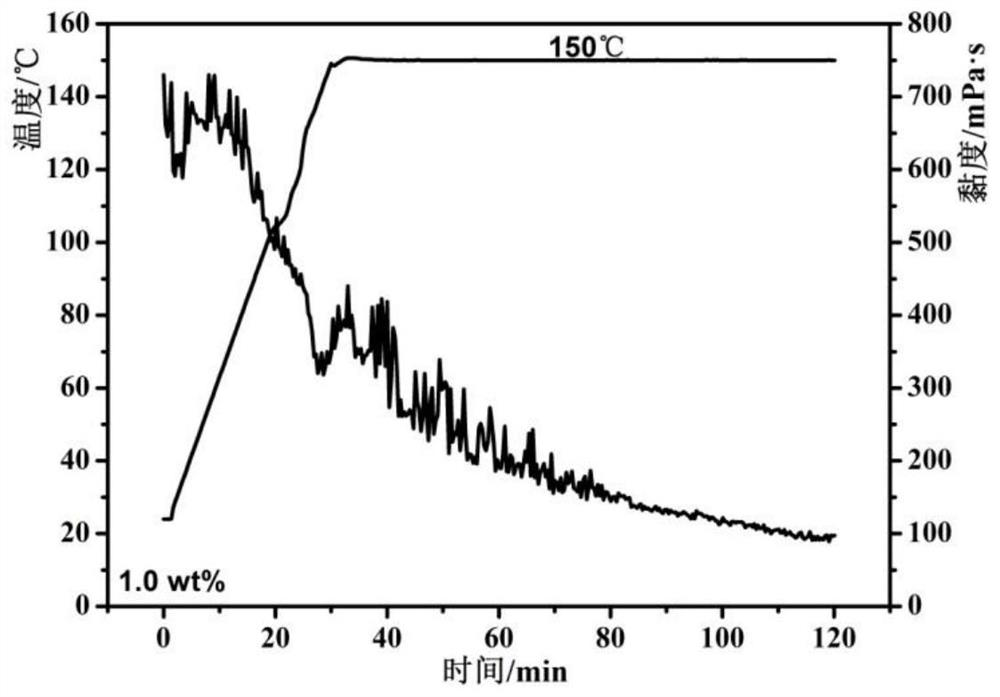

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com