Rubber containing copper tailings as well as preparation method and application of rubber

A technology of copper tailings and rubber, applied in the field of rubber materials, can solve problems such as insufficient compatibility, achieve the effects of improving various performances, reducing experimental procedures, and easy mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

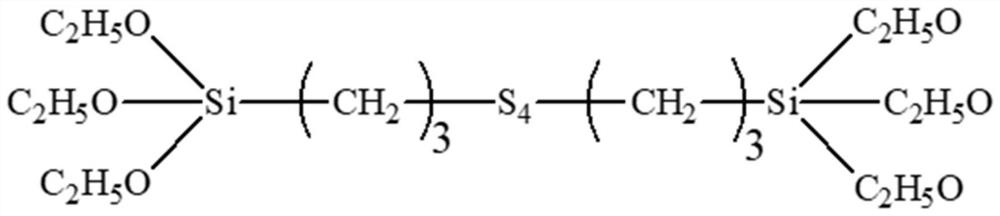

[0050] A kind of rubber containing copper tailings, including natural rubber, 10phr copper tailings (phr represents the number of grams added per 100g of natural rubber base material, that is, the mass ratio of copper tailings to natural rubber is 1:10), oxidation Zinc, antioxidant 4010NA, stearic acid, silane coupling agent Si69, accelerator D, accelerator CZ and sulfur, the specific reagent content and process parameters of each step are as shown in Table 2, including the following preparation steps:

[0051] (1) Tailings pretreatment: After drying the copper tailings, first crush them with a jaw crusher, and then grind them with a planetary ball mill to grind the copper tailings into powder;

[0052] (2) Rubber internal mixing process: set the initial temperature of the internal mixer to 80°C-85°C, and the rotational speed to 25r / min, add masticated natural rubber, increase the rotational speed to 40r / min, and add after mixing for 30s Zinc oxide, anti-aging agent 4010NA, st...

Embodiment 4

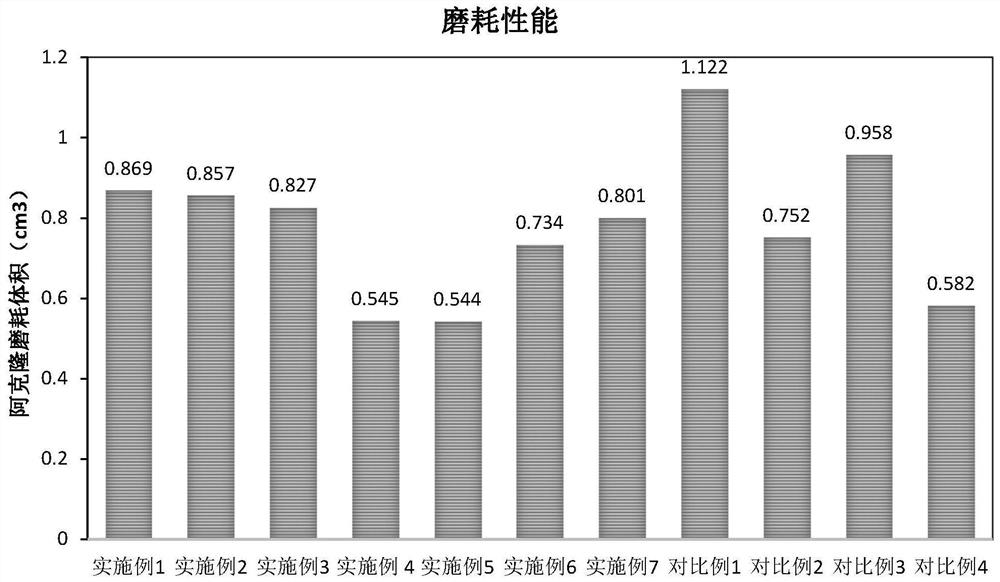

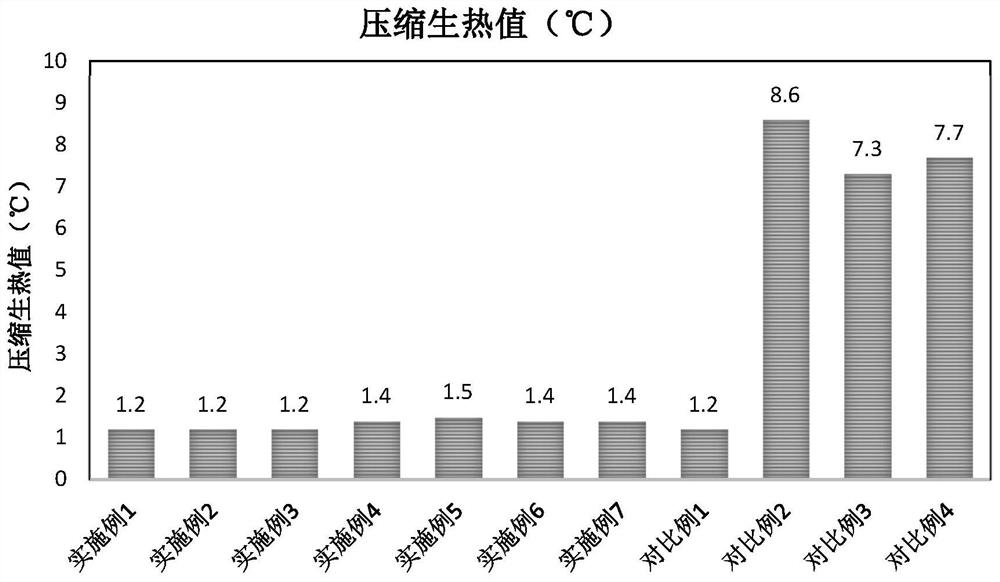

[0059] A kind of rubber containing copper tailings, each step and the reagents used in each step, process parameters are all the same as embodiment 3, the difference is that the addition of copper tailings is 30phr (the quality of copper tailings and natural rubber The ratio is 3:10), the mass ratio of copper tailings and Si69 is 10:1, specifically, the amount of copper tailings added is 30g, and the amount of Si69 added is 3g.

Embodiment 5

[0061] A kind of rubber containing copper tailings, each step and the reagents used in each step, process parameters are all the same as embodiment 3, the difference is that the addition of copper tailings is 50phr (the quality of copper tailings and natural rubber The ratio is 5:10), the mass ratio of copper tailings to Si69 is 10:1, specifically, the amount of copper tailings added is 50g, and the amount of Si69 added is 5g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com