Preparation method and device of phosphorus-containing intrinsic flame-retardant polyacrylate composite material

A polyacrylate and composite material technology, applied in chemical instruments and methods, mixers with rotary stirring devices, mixers, etc. materials, poor mixing quality, etc., to achieve the effect of intrinsic flame retardant and bonding performance promotion, intrinsic flame retardant and bonding performance, and improving the degree of mixing and stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

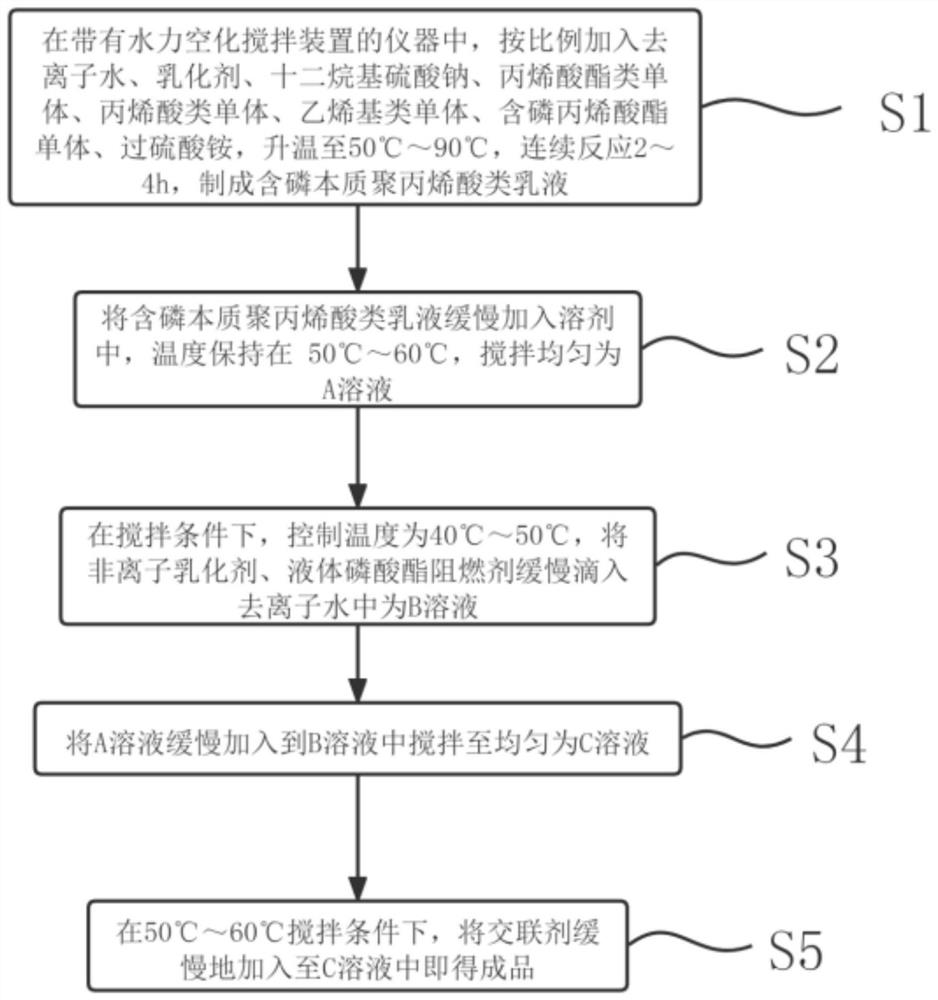

[0059] Such as figure 1 Shown, a kind of preparation method of phosphorus-containing essential flame-retardant polyacrylate composite material comprises following components:

[0060] Phosphorus-containing essential polyacrylic acid emulsion 75-90 parts;

[0061] 5-20 parts of cross-linking agent;

[0062] 2-10 parts of liquid phosphate flame retardant;

[0063] 4 to 20 parts of deionized water;

[0064] 0.3-3 parts of nonionic emulsifier;

[0065] Among them, the phosphorus-containing essential polyacrylic acid emulsion is prepared from raw materials comprising the following substances:

[0066] 50-70 parts of acrylate monomer;

[0067] 5-20 parts of acrylic monomer;

[0068] 10-40 parts of vinyl monomers;

[0069] Phosphorus-containing acrylate monomer 3-15 parts;

[0070] 0.2-2 parts of emulsifier;

[0071] 0.1 to 1 part of sodium lauryl sulfate;

[0072] 0.1 to 0.5 parts of ammonium persulfate;

[0073] 150-300 parts of deionized water;

[0074] The preparation...

no. 2 example

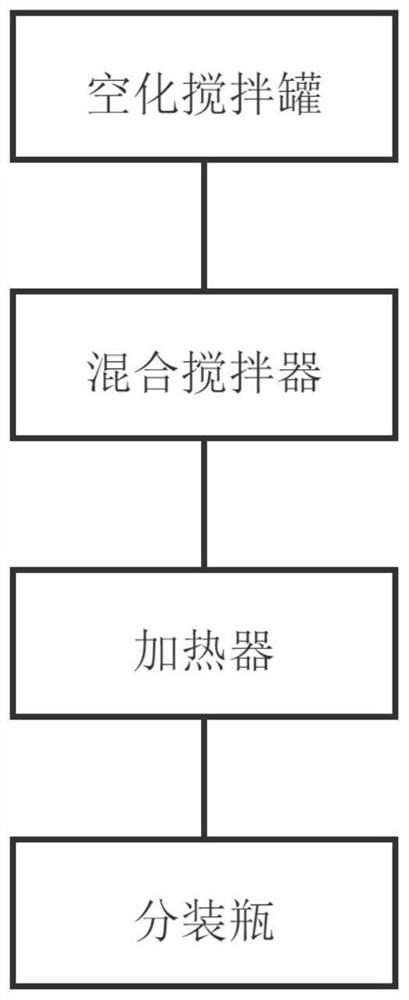

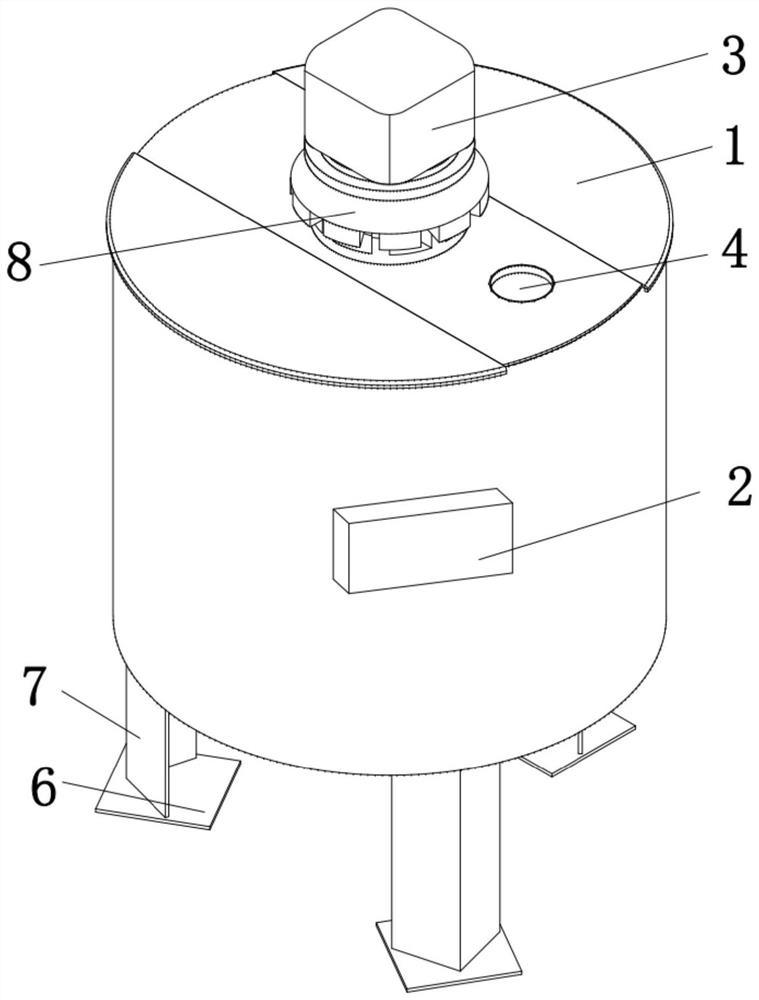

[0089] Such as Figure 2-7 As shown, based on the preparation method of a phosphorus-containing intrinsically flame-retardant polyacrylate composite material provided in the first embodiment, a preparation device for phosphorus-containing intrinsically flame-retardant polyacrylate composite material is required in actual use, and the device includes: Cavitation stirring tank: used to prepare phosphorus-containing essential polyacrylic acid emulsion; mixing agitator: used to mix and stir raw materials and solvents to prepare the required A, B and C solutions; heater: provide the best temperature for mixing and stirring Conditions; sub-bottling: sub-packaging A, B and C solutions.

[0090] Therefore, this embodiment proposes a hydraulic cavitation stirring device, which includes a tank body 1, the tank body 1 mainly stores the material to be stirred, and a controller 2 is provided on one side of the tank body 1, and the controller 2 electrically controls each electrical componen...

no. 3 example

[0102] Such as Figure 8-12 As shown, based on the preparation device of a phosphorus-containing intrinsically flame-retardant polyacrylate composite material provided in the second embodiment, in actual use, due to the uncertainty of the volume of the mixture monomer, during the stirring process, the mixture monomer When it enters the vortex chamber 15 along the first cavitation chamber 14, it will be blocked. At the same time, because the mixed emulsion has a certain adhesiveness, the mixed emulsion will adhere to the top surface of the spiral blade 11 during the stirring process, affecting the spiral. For the normal use of blade 11 stirring, in order to solve the above problems, improve the clearing of the device and remove the mixed emulsion adhered to the surface of the spiral blade 11, the preparation device of the phosphorus-containing intrinsically flame-retardant polyacrylate composite material also includes: a vortex chamber 15 A plurality of sets of vortex plates 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com