Composite functional filament with core-shell structure and preparation method thereof

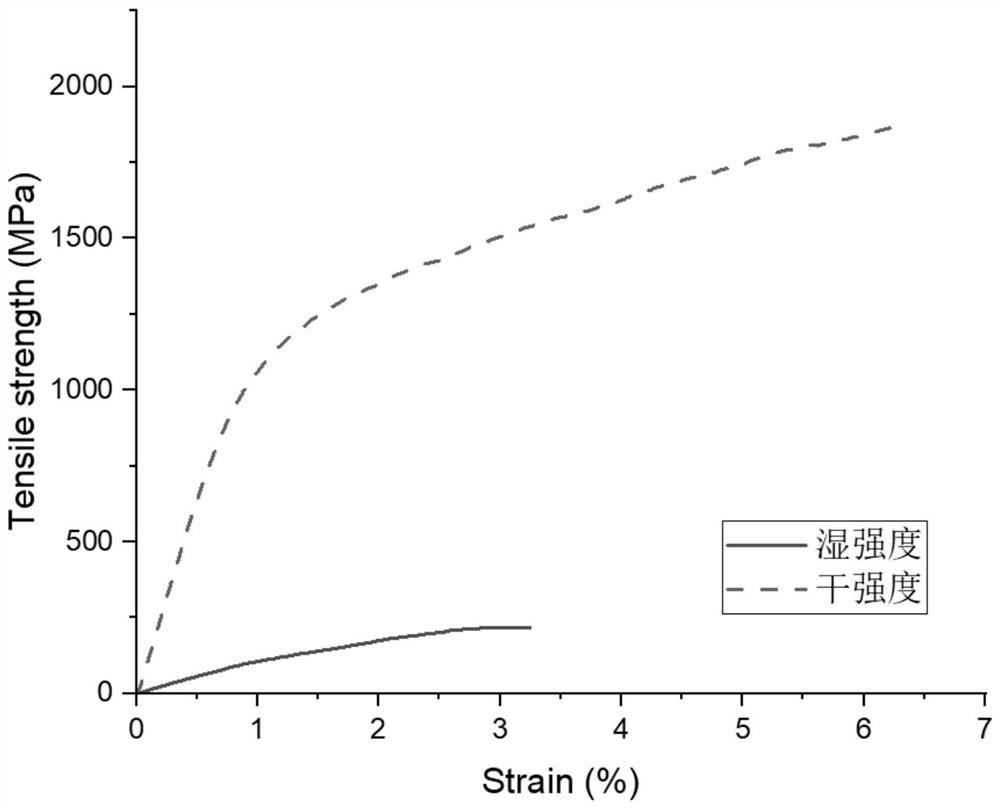

A technology with composite functions and core-shell structure, which is applied in the manufacture of fire-resistant and flame-retardant filaments, conductive/antistatic filaments, rayon, etc., can solve the problems of low wet strength of filaments, low strength of Slow speed and other problems, to achieve the effect of improving spinning efficiency, broad application prospects and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

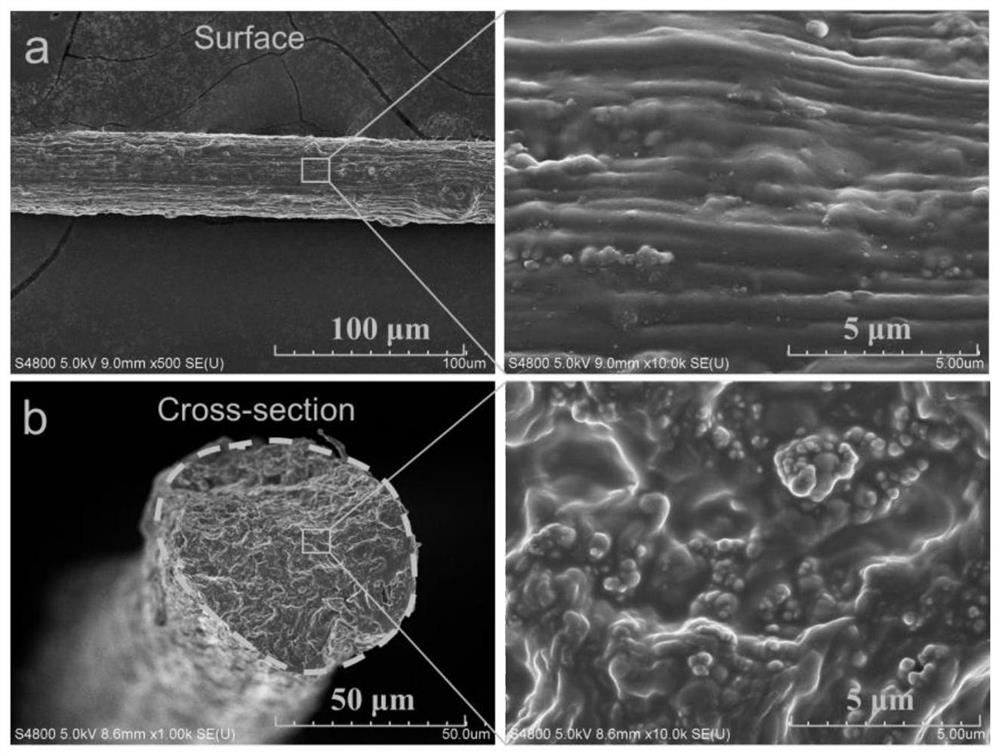

Embodiment 1

[0033]Add 100g of cationic nanocellulose to an appropriate amount of water to prepare a dispersion with a concentration of 0.1wt%, and add 100g of TEMPO oxidized nanocellulose (anionic nanocellulose) to an appropriate amount of water to prepare a dispersion with a concentration of 0.5wt%. The charge density of the cationic nanocellulose is 0.5mmol / g, and the charge density of the anionic nanocellulose is 1.5mmol / g. To the cationic nanocellulose dispersion, add 250 g of polyvinyl alcohol solution (dry weight 5 g) and 0.1 g of melamine formaldehyde resin with a concentration of 2 wt % successively, and stir separately to mix uniformly to obtain cationic nanocellulose dispersion I. Add 5 g of borax to the anionic nanocellulose dispersion, stir and mix uniformly to obtain anionic nanocellulose dispersion I. Anionic nanocellulose dispersion I was dropped on the bottom of a spinning tube with a diameter of 10 mm, then cationic nanocellulose dispersion I was dropped, and the interfac...

Embodiment 2

[0038] Add 100g of cationic guar gum to an appropriate amount of water to prepare a solution with a concentration of 1.2wt%; add 100g of TEMPO oxidized nanocellulose (anionic nanocellulose) to an appropriate amount of water to prepare a dispersion with a concentration of 0.1wt%. Wherein, the charge density of the cationic guar gum is 0.5 mmol / g, and the charge density of the anion nanocellulose is 3.0 mmol / g. In the cationic guar gum solution, adding concentration successively is that the cationic polyacrylamide solution 20g (dry weight 0.1g) of 0.5wt% and the polyamide polyamine epichlorohydrin solution 40g (dry weight 5g) that concentration is 12.5wt%, And stir separately to mix uniformly, obtain cationic guar gum solution I. Add 20 g of nano-ferric iron tetroxide to the anionic nanocellulose dispersion, and stir to make the mixture uniform to obtain the anionic nanocellulose dispersion I. Anionic nanocellulose dispersion I was dropped on the bottom of a spinning tube with ...

Embodiment 3

[0044] Add 100g of chitosan to an appropriate amount of water to prepare a solution with a concentration of 1.0% by weight; add 100g of sodium alginate to an appropriate amount of water to prepare a solution with a concentration of 1.2%. Among them, the charge density of chitosan is 3.0mmol / g, and the charge density of sodium alginate is 1.0mmol / g. In the chitosan solution, add successively the glyoxal polyacrylamide solution 50g (dry weight 0.25g) and epichlorohydrin 0.5g that concentration is 0.5wt%, and stir respectively and make mixing, obtain cationic chitosan solution I . Add 1 g of nano-silver particles to the sodium alginate solution, stir to make the mixture uniform, and obtain the anionic sodium alginate solution I. The sodium alginate solution I is dripped into the bottom of the spinning tube with a diameter of 50mm, and then the chitosan solution I is dripped into it; then the two interface layers are stretched upwards at a stretching speed of 50cm / min to obtain w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com