Lithium ion battery

A lithium-ion battery and lithium-ion technology, applied in the direction of secondary batteries, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of increased internal resistance, increased electrode thickness, and weakened fast charging effect, achieving good cycle life and Effects of safety and high charging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In a specific embodiment, the present invention provides a kind of preparation method of lithium ion battery, and described preparation method comprises:

[0039] The positive pole piece, diaphragm, and negative pole piece are prepared into stacked cores by a Z-shaped lamination machine, and then the lithium-ion battery is obtained through a tab welding machine, a soft pack battery side seal, top seal, liquid injection, and pre-sealing. .

[0040] The present invention also provides a method for preparing a positive pole piece, the preparation method comprising:

[0041] Mix the positive electrode active material, conductive agent and binder, add a solvent, homogenize, coat the surface of the positive electrode current collector, and dry and roll to obtain the positive electrode sheet;

[0042] The present invention also provides a method for preparing a negative electrode sheet, the preparation method comprising:

[0043] The negative electrode active material, the c...

Embodiment 1

[0045] This embodiment provides a lithium-ion battery, the lithium-ion battery includes a positive pole piece, a negative pole piece, a separator, and an electrolyte;

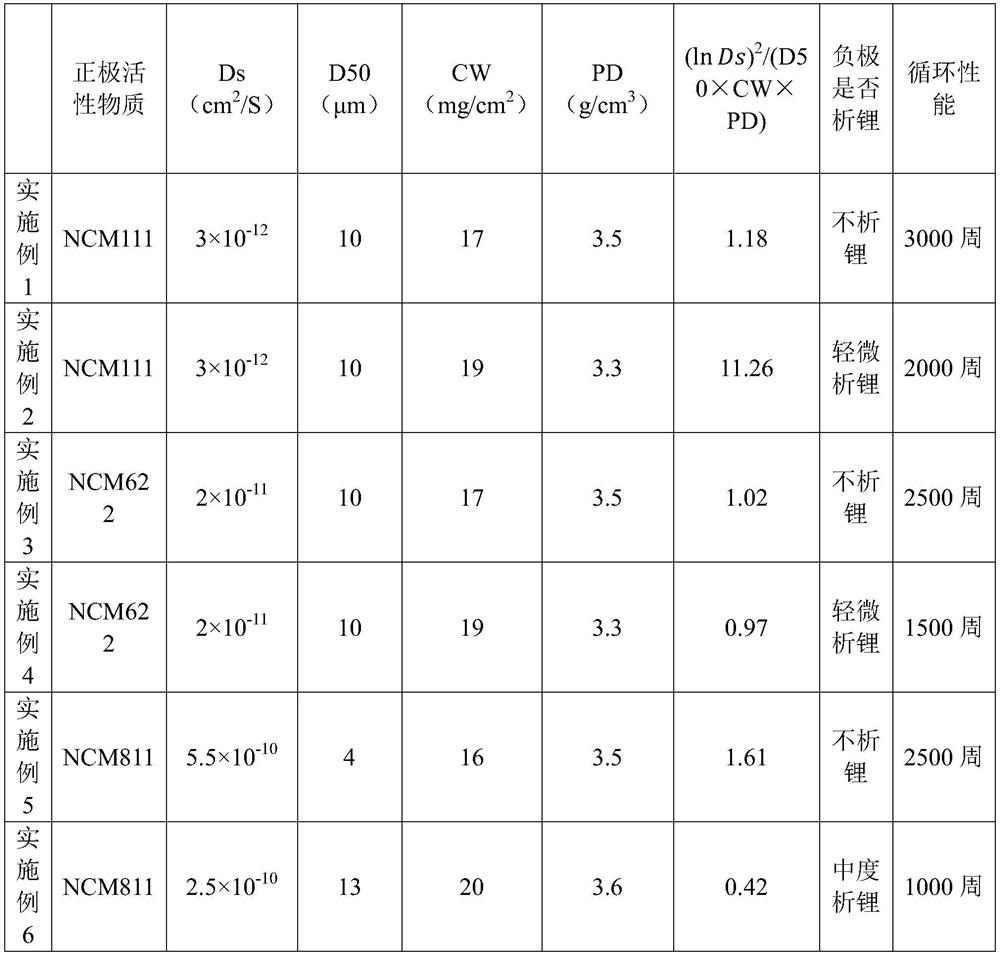

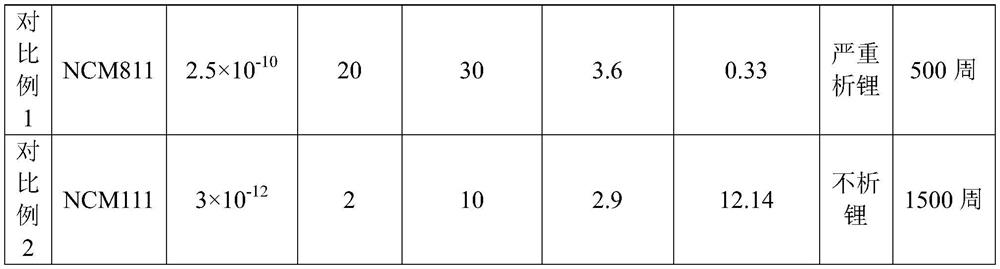

[0046] The following values of the positive pole piece are shown in Table 1: Ds is the lithium ion solid-phase diffusion coefficient in the positive pole piece, D50 is the median diameter of the positive active material in the positive pole piece, and CW is the positive pole piece The areal density of the middle electrode layer, PD is the compacted density of the positive pole piece, and (lnDs) 2 / (D50×CW×PD) result.

[0047] The positive electrode active material in the positive electrode sheet is NCM11, the conductive agent is carbon nanotubes, and the binder is polytetrafluoroethylene;

[0048] The negative electrode active material in the negative electrode sheet is natural graphite, the conductive agent is carbon nanowire, and the binding agent is styrene-butadiene rubber and sodium carboxymethyl cellul...

Embodiment 2

[0054] This embodiment provides a lithium ion battery, its positive electrode active material, Ds, D50, CW, PD and (lnDs) 2 / (D50×CW×PD) is also shown in Table 1.

[0055] All the other preparation methods and parameters are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com