Knee joint local prosthesis and personalized design method thereof

A knee joint and prosthesis technology, applied in the field of knee joint partial prosthesis and its personalized design, can solve the problems of low service life, long operation time, and reduce the possibility of treatment, so as to increase the wear resistance rate, reduce the The effect of production cost and shortening of preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a kind of individualized design method of partial prosthesis of knee joint, comprises the following steps:

[0026] Step 1. Through the CT scan data of the knee joints of multiple patients, prosthesis data models with various specifications and models and dense size intervals are obtained, and a database of real knee joint bone models of patients is established. After the obtained CT scan data is segmented and repaired, it is reconstructed in 3D to obtain a 3D digital model of the knee joint. Many real 3D digital models of the knee joint form a large database.

[0027] Step 2: Compare the target bone data with the data model of the knee joint bone model database established in step 1, match the bone data with high similarity, and retrieve the local intact bone data corresponding to the lesion of the target patient;

[0028] Step 3. Design the bone-covered prosthesis according to the intact local bone data retrieved in step 2, so that the covered prosthesis...

Embodiment 2

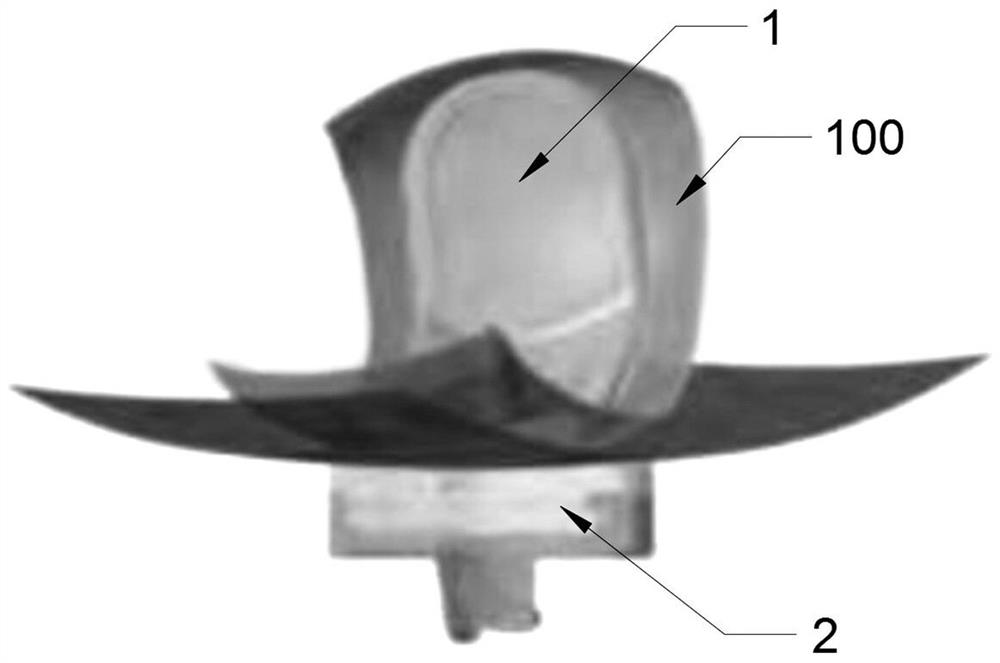

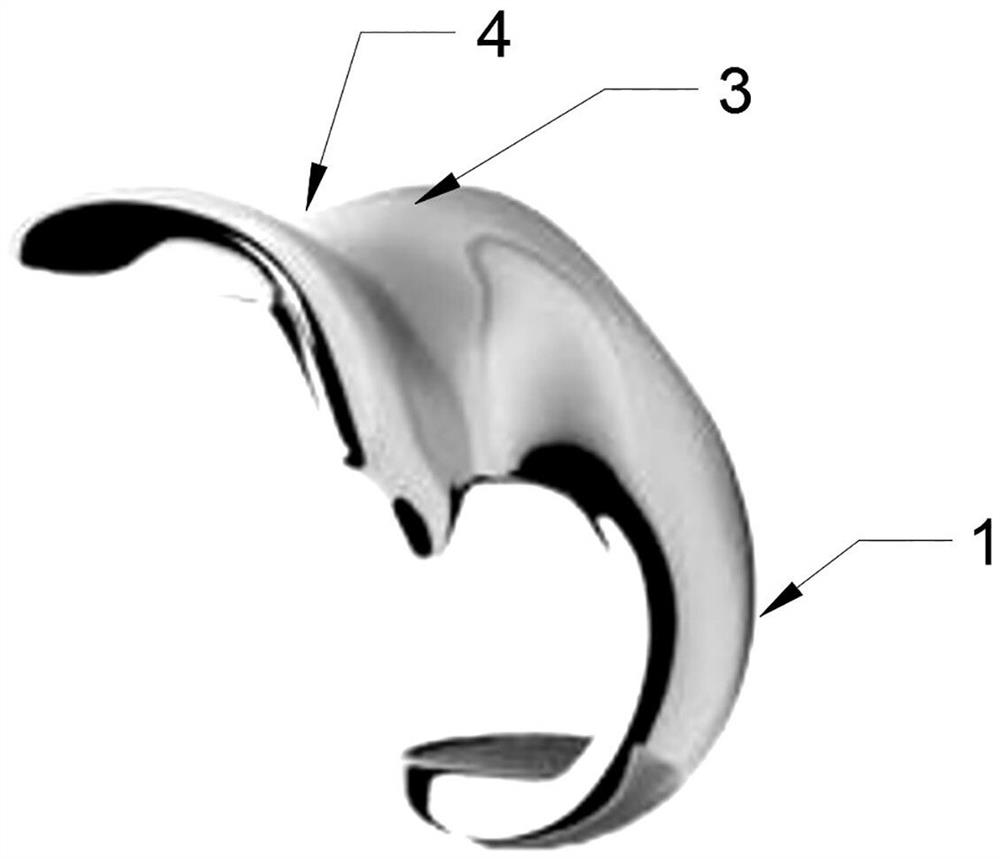

[0030] Embodiment two, the present invention also provides a kind of partial prosthesis of knee joint, comprise the condylar process implant 1 that matches with human femoral condyle, the bottom of described condylar process implant 1 is in the final groove on the knee joint surface Before termination, the condylar implant 1 is matched one-to-one with the tibial plateau pad 2 . The peripheral contour of described condylar process implant 1 is polygonal in space, and the edge place of described peripheral contour is provided with concave front flange engineering curved surface, and described condylar process implant 1 is matched with tibial plateau Pad 2 is connected by an interference fit with minimal micro-motion. figure 2 The first demonstration surface 100 in the figure shows the form of this engineering curved surface in detail, which ensures the fitting degree of the condyle implant 1 and the original human bone, and avoids the prosthesis and human bone from being not ti...

Embodiment 3

[0035] Embodiment 3, a method for manufacturing a knee joint condyle implant, using a cobalt-chromium-molybdenum alloy as a base material for manufacturing and molding. The composition percentage of the cobalt-chromium-molybdenum alloy is: Co matrix, Cr2 6.5-30.0%, Mo 4.5-7.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com