Chitosan-based nanofiber wound dressing with adhesiveness and antibacterial property and preparation method of chitosan-based nanofiber wound dressing

A nanofiber and wound dressing technology, applied in the field of chitosan-based nanofiber wound dressing and its preparation, can solve the problem of poor hydrophilicity, solubility and tissue adhesion, and unsatisfactory antibacterial performance of drug-resistant bacteria chitosan, etc. problem, to achieve the effect of good water absorption, antibacterial performance promotion, and controlled drug release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

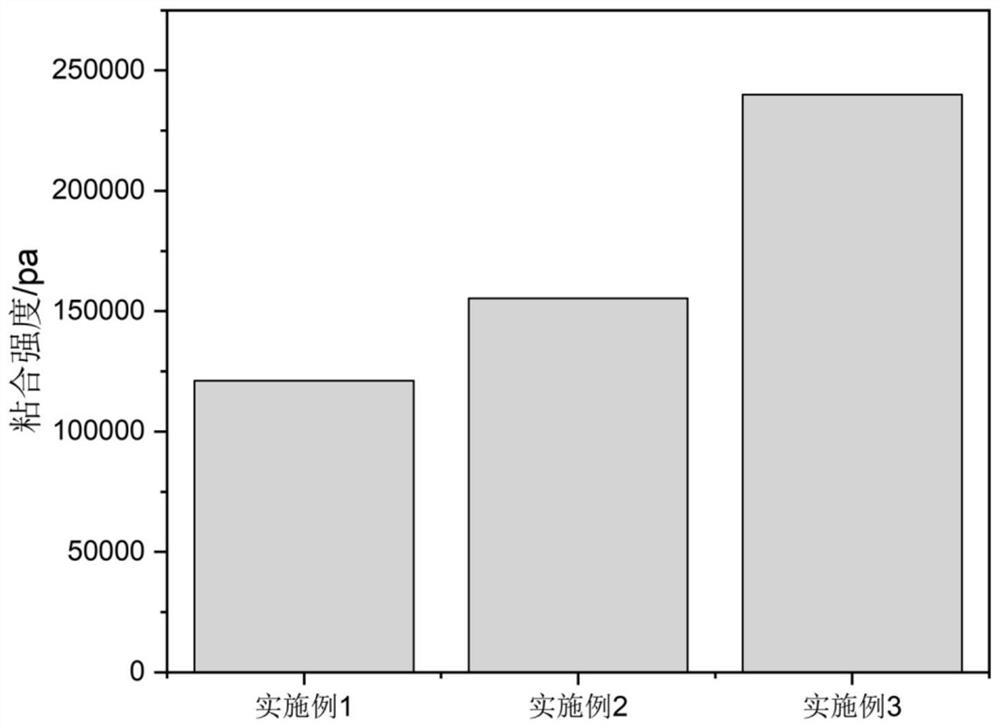

Embodiment 1

[0034] 1 gram of polyvinyl alcohol was dissolved in 10 ml of deionized water to obtain a polyvinyl alcohol solution with a concentration of 10% M / V.

[0035] The above polyvinyl alcohol solution was subjected to electrospinning. The conditions of electrospinning were high voltage 15kv, receiving distance 10cm, injector advancing speed 0.3ml / h, drum collector rotating speed 500rpm. After electrospinning, the obtained samples were collected and vacuum-dried More than 12h, save the sample.

Embodiment 2

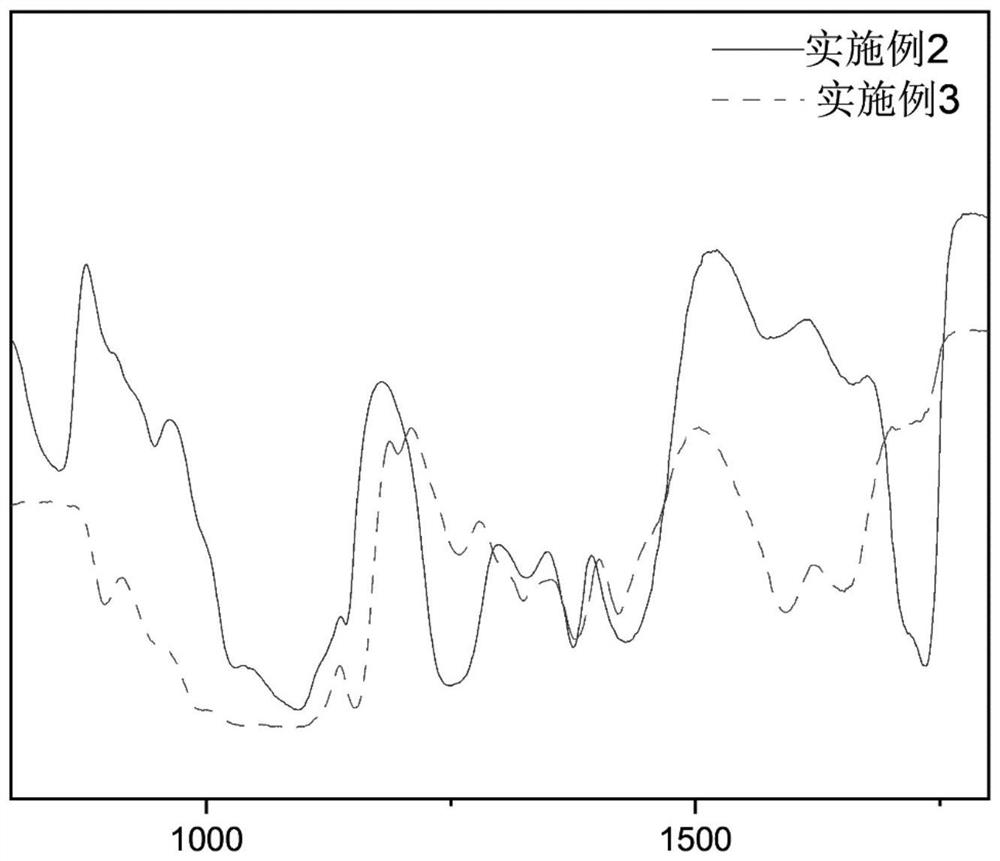

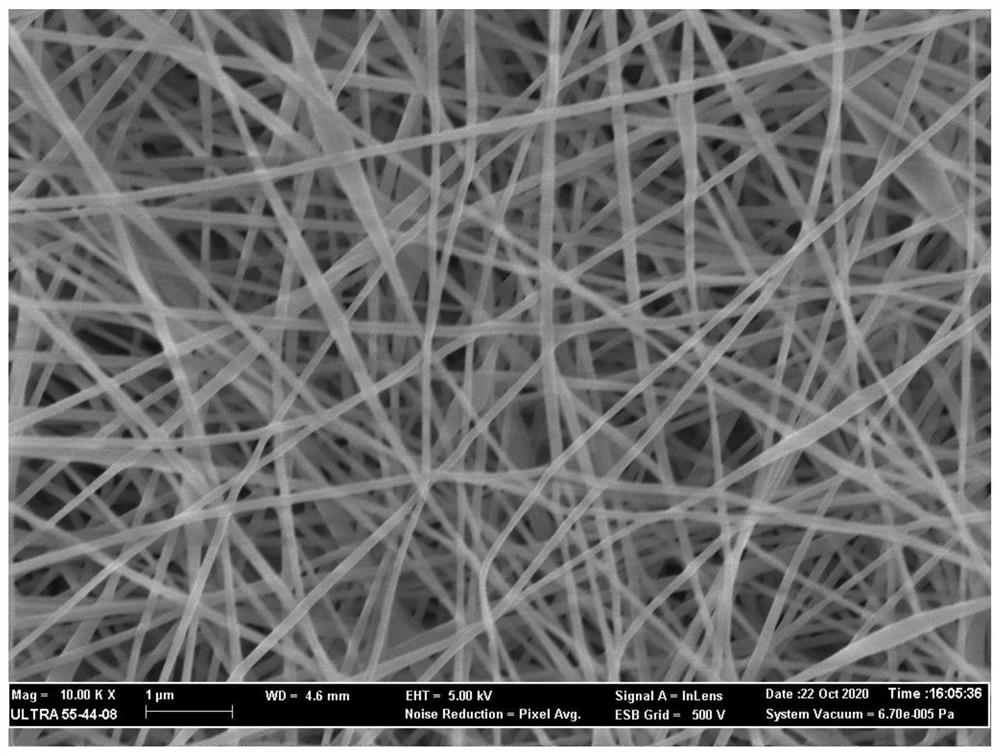

[0037] 1 gram of polyvinyl alcohol was dissolved in 10 ml of deionized water to obtain a polyvinyl alcohol solution with a concentration of 10% M / V. 0.3 gram of chitosan was dissolved into a volume concentration of 1% V / V acetic acid solution to obtain a concentration of 3% M / V chitosan solution.

[0038] The above-mentioned polyvinyl alcohol solution is used as a shell solution, and the above-mentioned chitosan solution is used as a core solution, and the solutions are injected into corresponding syringes. Carry out coaxial electrospinning, the conditions of electrospinning are high voltage 15kv, receiving distance 10cm, injector advancing speed is 0.3ml / h, drum collector rotating speed 500rpm, after electrospinning, collect the obtained sample, vacuum dry more than 12h, Save the sample.

Embodiment 3

[0040] 1 gram of polyvinyl alcohol was dissolved in 10 ml of deionized water to obtain a polyvinyl alcohol solution with a concentration of 10% M / V. Dissolving 0.3 gram of chitosan into a volume concentration of 1% V / V acetic acid solution to obtain a concentration of 3% M / V chitosan solution, 0.02 gram of dopamine hydrochloride, 0.05 gram of 5-aminolevulinic acid in the shell In the polysaccharide solution, a 5-aminolevulinic acid-dopamine hydrochloride-chitosan solution is obtained. The above-mentioned polyvinyl alcohol solution is used as a shell solution, and the above-mentioned chitosan-dopamine hydrochloride solution is used as a core solution, and the solutions are injected into corresponding syringes. Carry out coaxial electrospinning, the conditions of electrospinning are high voltage 15kv, receiving distance 10cm, injector advancing speed is 0.3ml / h, drum collector rotating speed 500rpm, after electrospinning, collect the obtained sample, vacuum dry more than 12h, S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com