Resin colored tape suitable for multiple types of base materials and preparation method of resin colored tape

A multi-type, resin technology, applied in the direction of ink ribbon, coating, printing, etc., can solve the problem of poor adaptability of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

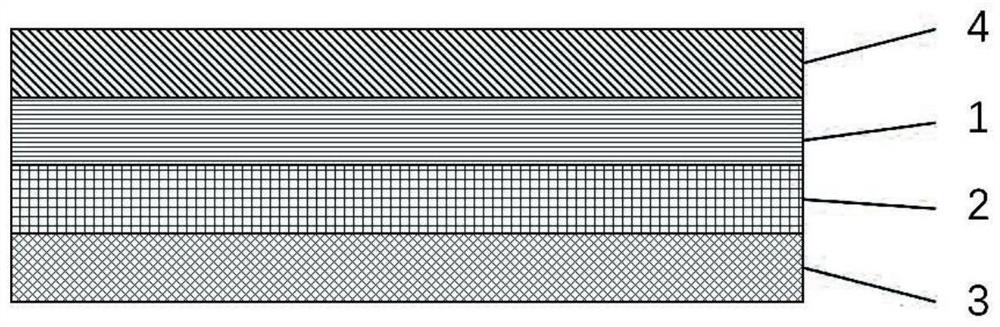

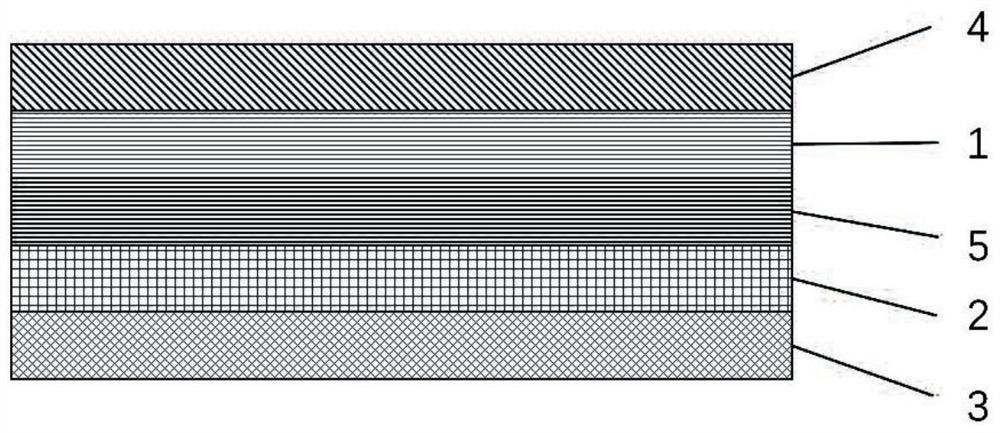

[0052] Such as figure 1 As shown, this embodiment provides a resin ribbon suitable for various types of substrates, including a back coat 4, a substrate 1, a pigment layer 2, and an adhesive layer 3 that are laminated sequentially from top to bottom;

[0053] Wherein, the substrate 1 is a polyethylene terephthalate film;

[0054] Back coating 4 is formed by back coating liquid coating, and back coating liquid is to get 5 mass parts of polyurethane modified silicone resins, 5 mass parts of acrylic acid modified silicone resins, 3 mass parts of polyvinyl acetal resins, 3 parts by mass of polyvinyl butyral resin, 2 parts by mass of talc, 1 part by mass of aluminum hydroxide, 1 part by mass of silicon dioxide, 2 parts by mass of leveling agent, 2 parts by mass of dispersant, 2 parts by mass of antistatic agent 1. Add 1 mass part of isocyanate to the back coating solution made in the mixed solvent of 100 mass parts of 2-butanone and 100 mass parts of toluene;

[0055] The pigment...

Embodiment 2

[0083] The difference between this embodiment and Example 1 is that the pigment layer is formed by coating a pigment liquid, and the pigment liquid is obtained by taking 8 mass parts of polyester resin, 5 mass parts of methacrylic resin, 5 mass parts of polyolefin resin, 2 parts by mass of styrene-based resin, 1 part by mass of ethylene-vinyl acetate copolymer, 1 part by mass of PE wax, 1 part by mass of carnauba wax, 1 part by mass of EVA wax, and 11 parts by mass of inorganic pigment are added to 33 parts by mass of 2-butanone The pigment liquid that makes in the mixed solvent of 32 parts by mass of toluene and toluene.

[0084] The adhesive layer is formed by coating the adhesive liquid, and the adhesive liquid is to get 8 mass parts of polyester resin, 6 mass parts of methacrylic resin, and 2 mass parts of ethylene-vinyl acetate copolymer to 42 mass parts of 2-butanone and toluene. Adhesive made from 42 parts by mass of mixed solvent.

[0085] According to the test method...

Embodiment 3

[0092] The difference between this embodiment and Example 1 is that the pigment layer is formed by coating the pigment liquid, and the pigment liquid is obtained by taking 10 mass parts of polyester resin, 3 mass parts of methacrylic resin, 3 mass parts of polyolefin resin, 1 mass part of styrene-based resin, 2 mass parts of ethylene-vinyl acetate copolymer, 1 mass part of PE wax, 1 mass part of carnauba wax, 1 mass part of EVA wax, and 12 mass parts of inorganic pigments are added to 33 mass parts of 2-butanone The pigment liquid that makes in the mixed solvent of 33 parts by mass of toluene and toluene.

[0093] The adhesive layer is formed by coating with an adhesive liquid, and the adhesive liquid is to add 6 mass parts of polyester resin, 3 mass parts of methacrylic resin, and 5 mass parts of ethylene-vinyl acetate copolymer to 43 mass parts of 2-butanone and toluene. Adhesive made from 43 parts by mass of mixed solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com