Graphene film and preparation method thereof

A graphene film and graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve difficult problems and achieve excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

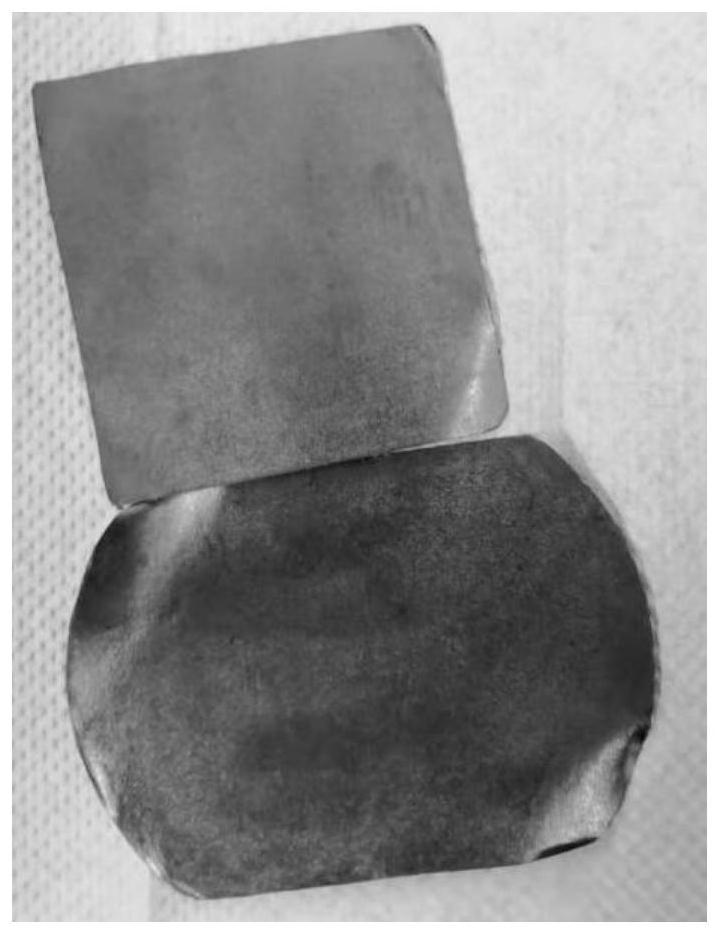

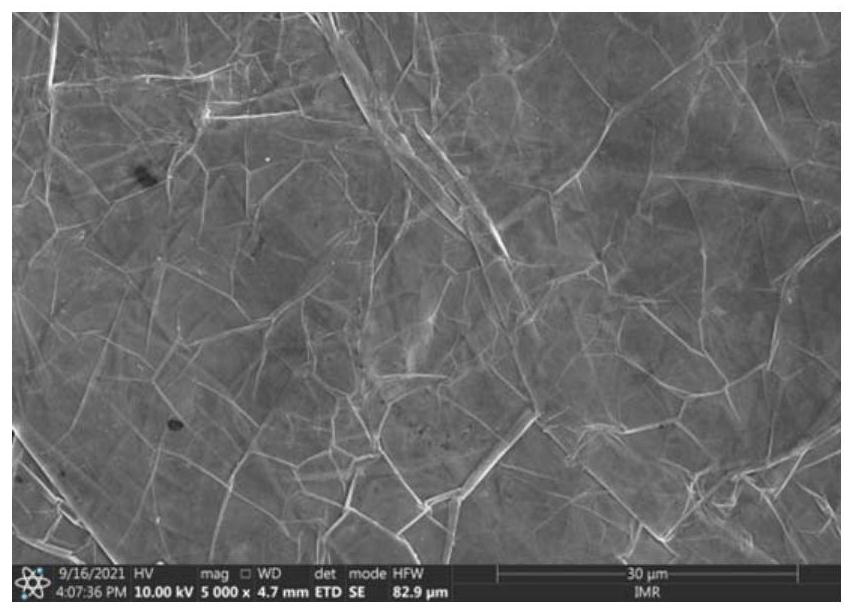

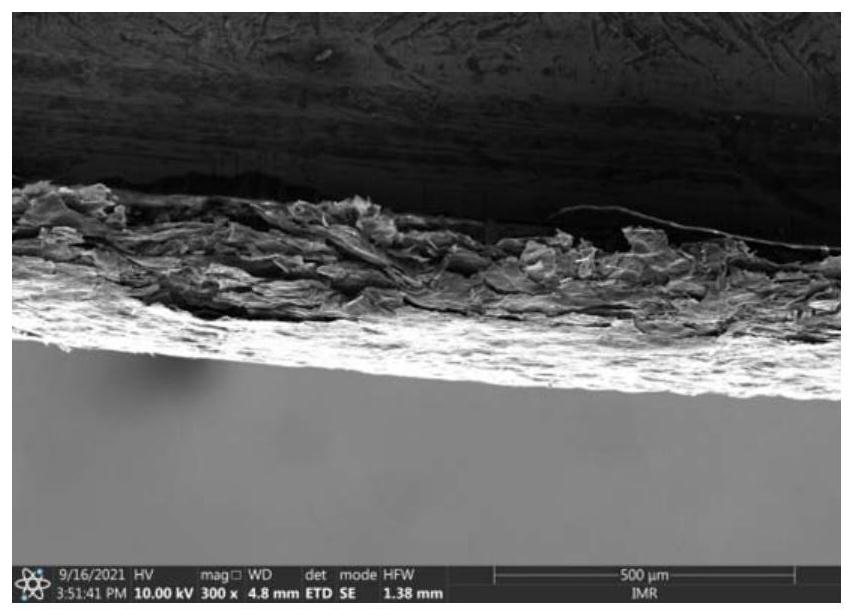

Image

Examples

Embodiment 1

[0042] In this embodiment, the reaction furnace cavity is heated to 1000°C under a nitrogen protective atmosphere, and a compound with a porosity of 500PPI and a surface density of 2.5g / cm is added to the constant temperature zone of the reaction furnace cavity. 3 The three-dimensional interconnected high-porosity and high-density porous nickel is introduced into hydrogen gas and kept warm for 10 minutes. The flow rate of hydrogen gas is 600 sccm. The flow rate of the gas is 620 sccm, the flow ratio of ethylene and hydrogen in the mixed gas is 1:30, and the reaction time is 30 minutes. Graphene is catalyzed and grown on the surface of a three-dimensionally connected high-porosity and high-density porous nickel substrate.

[0043] Take out the three-dimensional interconnected high-density graphene skeleton grown on the porous metal substrate under a nitrogen protective atmosphere, put it into a 3mol / L hydrochloric acid aqueous solution (etching solution), and keep it at 80°C for...

Embodiment 2

[0050] Under the protective atmosphere of argon, the reaction furnace cavity is heated to 1000°C, and the porosity is 800PPI, and the surface density is 3.5g / cm2. 3 The three-dimensional interconnected high-porosity and high-density porous copper is fed with hydrogen, and the flow rate of hydrogen is 500 sccm. The function of feeding hydrogen first is to remove the oxide layer on the surface of the substrate; The flow ratio of methane and hydrogen in the mixed gas is 510sccm, the flow ratio of methane and hydrogen in the mixed gas is 1:50, and the reaction time is 50min. Graphene is catalyzed and grown on the surface of a three-dimensionally connected high-porosity and high-density porous copper substrate.

[0051] Take out the three-dimensional interconnected high-density graphene skeleton grown on the porous metal substrate under a nitrogen protective atmosphere, put it into 2mol / L sulfuric acid aqueous solution (etching solution), and keep it at 80°C for 120min to completely...

Embodiment 3

[0053] Under the protective atmosphere of argon, the reaction furnace cavity is heated to 1100°C, and the porosity is 1100PPI, and the surface density is 5.1g / cm2. 3 The three-dimensionally connected porous nickel with high porosity and high density is fed with hydrogen, and the flow rate of hydrogen is 500 sccm. The flow rate of the gas is 1010sccm, the flow ratio of methane and hydrogen in the mixed gas is 1:50, and the reaction time is 70min. Graphene is catalyzed and grown on the surface of a three-dimensionally connected high-porosity and high-density porous nickel substrate.

[0054] Take out the three-dimensional interconnected high-density graphene skeleton grown on the porous metal substrate under a nitrogen protective atmosphere, put it into a 3mol / L aqueous hydrochloric acid solution (etching solution), and keep it at 80°C for 90 minutes to completely remove it. The nickel in the graphene skeleton is removed, and after the graphene skeleton is taken out, cleaned and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com