Method for preparing tobermorite phase landscape high-speed rail sound barrier from multi-element solid waste

A tobermorite and sound barrier technology, applied in the field of comprehensive utilization of resources, can solve the problems of increasing operating costs and worker workload, affecting the working life of sound barriers, corrosion and rusting of metal sound barriers, etc., to reduce production difficulty and The effect of artificial use, promoting sustainable and harmonious development, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

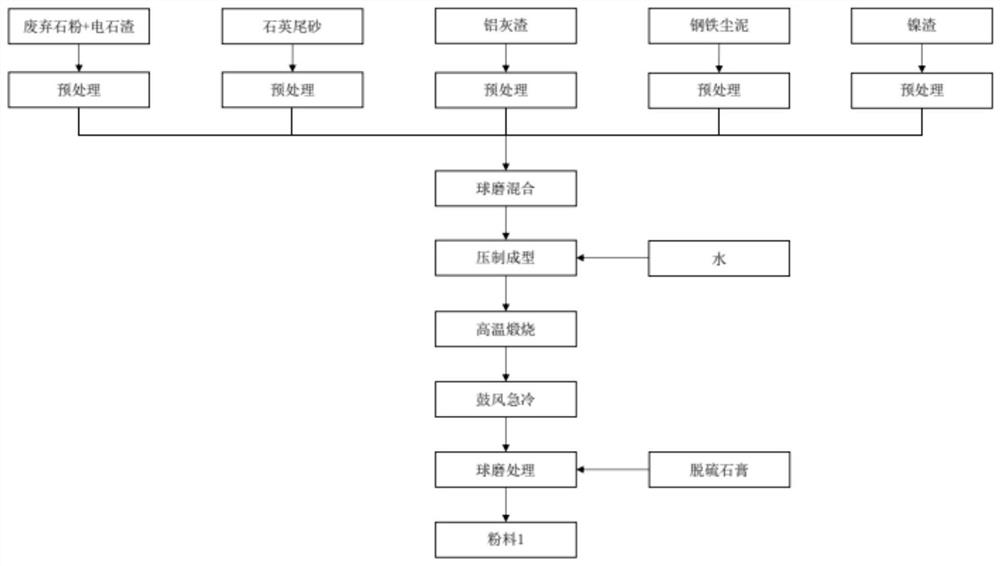

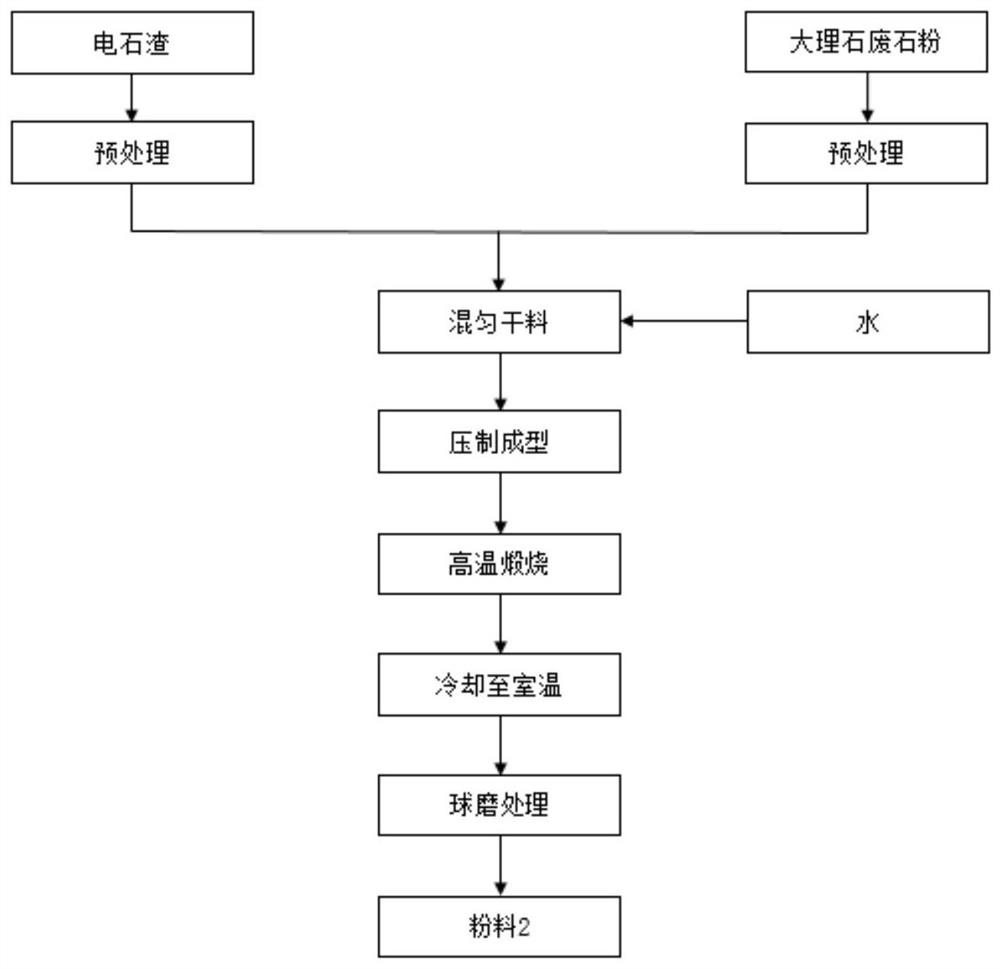

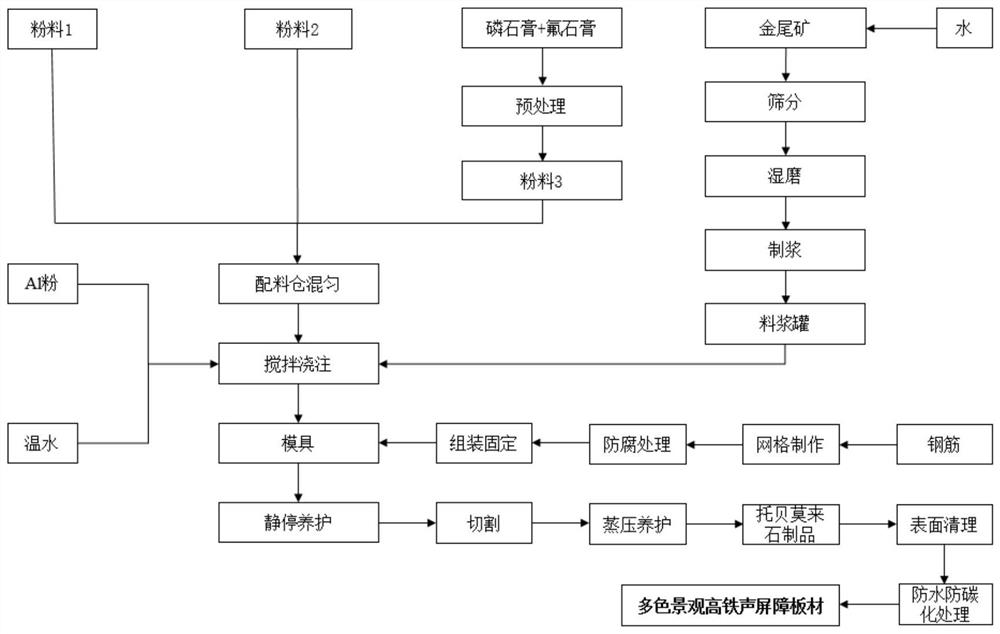

[0048] A method for preparing tobermorite landscape high-speed rail sound barriers from multi-component solid waste, including powder 1, powder 2, powder 3, preparation of slurry, pretreatment of steel bars, pouring molding, high-temperature autoclaving, and waterproofing Anti-carbonization treatment process.

[0049] The above-mentioned Tobermorite landscape high-speed rail sound barrier method includes the following steps:

[0050] S1. Pretreatment of waste stone powder + calcium carbide slag: firstly screen the waste stone powder and carbide slag to remove organic impurities in the waste stone powder and carbide slag, and then place them in an electric drying oven for drying for 12 hours (drying condition 105°C) , the dried calcium carbide slag and waste rock powder are mixed evenly according to the mass ratio of 30%:70%, put into the cement ball mill (rotating speed 48r / min), and grind until the specific surface area is 200m 2 / kg;

[0051] S2, pretreatment of quartz tai...

Embodiment 2

[0088] A method for preparing tobermorite landscape high-speed rail sound barriers from multi-component solid waste, including powder 1, powder 2, powder 3, preparation of slurry, pretreatment of steel bars, pouring molding, high-temperature autoclaving, and waterproofing Anti-carbonization treatment process.

[0089] The above-mentioned Tobermorite landscape high-speed rail sound barrier method includes the following steps:

[0090] S1. Pretreatment of waste stone powder + calcium carbide slag: firstly screen the waste stone powder and carbide slag to remove organic impurities in the waste stone powder and carbide slag, and then place them in an electric drying oven for drying for 12 hours (drying condition 105°C) , the dried calcium carbide slag and waste rock powder are mixed evenly according to the mass ratio of 40%:60%, put into the cement ball mill (rotating speed 48r / min), and grind until the specific surface area is 300m 2 / kg;

[0091] S2, pretreatment of quartz tai...

Embodiment 3

[0129] A method for preparing tobermorite landscape high-speed rail sound barriers from multi-component solid waste, including powder 1, powder 2, powder 3, preparation of slurry, pretreatment of steel bars, pouring molding, high-temperature autoclaving, and waterproofing Anti-carbonization treatment process.

[0130] The above-mentioned Tobermorite landscape high-speed rail sound barrier method includes the following steps:

[0131] S1. Pretreatment of waste stone powder + calcium carbide slag: firstly screen the waste stone powder and carbide slag to remove organic impurities in the waste stone powder and carbide slag, and then place them in an electric drying oven for drying for 12 hours (drying condition 105°C) , the dried calcium carbide slag and waste rock powder are mixed evenly according to the mass ratio of 50%:50%, put into the cement ball mill (rotating speed 48r / min), and grind until the specific surface area is 350m 2 / kg;

[0132] S2, pretreatment of quartz tai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com