Manufacturing method of quartz ceramic crucible

A technology of quartz ceramics and production methods, which is applied in the field of quartz ceramics, can solve the problems that ceramic coatings are prone to cracking, easy to fall off and enter the interior of silicon materials, etc., and achieve good corrosion resistance and high temperature resistance, good durability, and process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

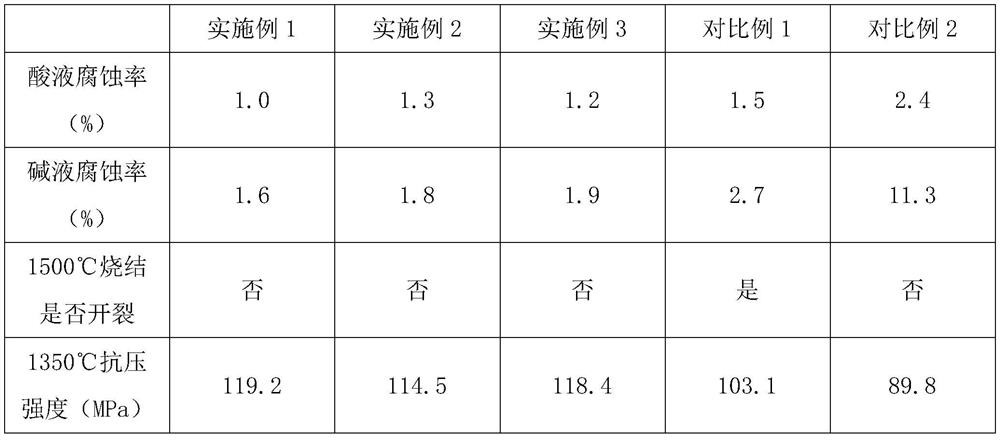

Examples

Embodiment 1

[0044] A method for manufacturing a quartz ceramic crucible, comprising the following steps:

[0045] Step 1, preparing the quartz ceramic crucible body:

[0046] Mix quartz sand powder, binder, and deionized water with a particle size of 50-100 μm and a purity of not less than 99.99% into a ball mill at a mass ratio of 10:0.8:2.5, and use zirconia beads for ball milling. The ball-to-material ratio is 2.5:1, the ball milling speed is 300rpm, the ball milling time is 3h, and then pour the ball milled slurry into a plaster mold, dry at room temperature for 22h, dry at 80°C for 12h, and then sinter in a graphite furnace Treatment, that is, first raise the temperature to 325°C, heat preservation treatment for 1.5h, then heat up to 750°C, heat preservation treatment for 1.5h, then heat up to 1200°C, heat preservation treatment for 4h, and cool to room temperature with the furnace to obtain the quartz ceramic crucible body; , the binder is obtained by mixing silica sol and methyl c...

Embodiment 2

[0059] A method for manufacturing a quartz ceramic crucible, comprising the following steps:

[0060] Step 1, preparing the quartz ceramic crucible body:

[0061] Mix quartz sand powder, binder, and deionized water with a particle size of 50-100 μm and a purity of not less than 99.99% into a ball mill at a mass ratio of 10:0.5:2, and use zirconia beads for ball milling. The ball-to-material ratio is 2:1, the ball milling speed is 200rpm, the ball milling time is 2h, then the ball milled slurry is poured into a plaster mold, dried at room temperature for 20h, dried at 60°C for 15h, and then sintered in a graphite furnace Treatment, that is, first raise the temperature to 300°C, heat preservation treatment for 2 hours, then heat up to 750°C, heat preservation treatment for 2 hours, then heat up to 1100°C, heat preservation treatment for 5 hours, and cool to room temperature with the furnace to obtain a quartz ceramic crucible body; The binder is obtained by mixing silica sol an...

Embodiment 3

[0074] A method for manufacturing a quartz ceramic crucible, comprising the following steps:

[0075] Step 1, preparing the quartz ceramic crucible body:

[0076] Mix quartz sand powder, binder, and deionized water with a particle size of 50-100 μm and a purity of not less than 99.99% into a ball mill at a mass ratio of 10:1:3, and use zirconia beads for ball milling. The ball-to-material ratio is 3:1, the ball milling speed is 500rpm, the ball milling time is 4h, then pour the ball milled slurry into a plaster mold, dry at room temperature for 24h, dry at 100°C for 15h, and then sinter in a graphite furnace Treatment, that is, first raise the temperature to 350°C, heat preservation treatment for 2 hours, then heat up to 800°C, heat preservation treatment for 1 hour, then heat up to 1200°C, heat preservation treatment for 3 hours, and cool to room temperature with the furnace to obtain a quartz ceramic crucible body; The binder is obtained by mixing silica sol and methylcellu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com