Pearl shell-imitated interface structure reinforced PBX compound and preparation method thereof

An interface structure, imitation pearl technology, applied in the direction of aromatic nitration composition, nitration acyclic/alicyclic/heterocyclic amine explosive composition, offensive equipment, etc., can solve the complex preparation process and poor molecular mechanical properties of interface modification and other problems, to achieve the effect of simple process, easy scale-up preparation, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

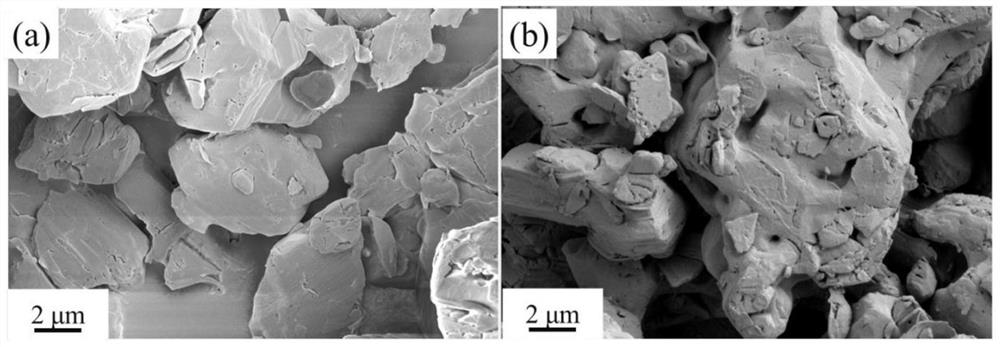

[0025] (1) Weigh 95g of 1,3,5-triamino-2,4,6-trinitrobenzene (TATB), 1600g of deionized water, and 1.92g of (hydroxymethyl)aminomethane (Tris) in a beaker, and stir at room temperature for 15min Then add 3.2g of dopamine, continue to stir and react at room temperature for 4 hours, filter, wash and dry to obtain PDA-coated explosive powder.

[0026] (2) Take by weighing 9 g of graphene aqueous solution with solid content of 5%, 5 g of cellulose solution with solid content of 1%, and 200 g of deionized water in a beaker, stir and disperse after 30 min and add the PDA bag obtained in step (1). After stirring and mixing the covered explosive powder for 2 hours, the temperature of the solution system was raised to 90°C by means of oil bath heating, and the water solvent was evaporated under continuous stirring. After a large amount of solvent volatilized (about 1 hour), the resulting mixture slurry was transferred to Thoroughly dry in an oven at 60°C to obtain explosive powder coat...

Embodiment 2

[0030] (1) Weigh 95g of 1,3,5-triamino-2,4,6-trinitrobenzene (TATB), 1600g of deionized water, and 1.92g of (hydroxymethyl)aminomethane (Tris) in a beaker, and stir at room temperature for 15min Then add 4.8g of dopamine, continue stirring and reacting at room temperature for 2.5 hours, filter, wash and dry to obtain PDA-coated explosive powder.

[0031] (2) Take by weighing 9.5 g of graphene aqueous solution with a solid content of 5%, 2.5 g of cellulose solution with a solid content of 1%, and 200 g of deionized water in a beaker, stir and disperse for 30 min and then add the obtained in step (1). For PDA-coated explosive powder, continue to stir and mix for 2 hours, heat the solution system to 90°C by means of oil bath heating, and evaporate the water solvent under continuous stirring. After a large amount of solvent volatilizes (about 1 hour), the resulting mixture slurry Transfer to an oven at 60°C for thorough drying to obtain explosive powder coated with an imitation pe...

Embodiment 3

[0035] (1) Weigh 95g of 1,3,5-triamino-2,4,6-trinitrobenzene (TATB), 1600g of deionized water, and 1.92g of (hydroxymethyl)aminomethane (Tris) in a beaker, and stir at room temperature for 15min Then add 3.2g of dopamine, continue to stir and react at room temperature for 4 hours, filter, wash and dry to obtain PDA-coated explosive powder.

[0036] (2) Take by weighing 7 g of graphene aqueous solution with a solid content of 5%, 15 g of cellulose solution with a solid content of 1%, and 200 g of deionized water in a beaker, stir and disperse for 30 min and then add the PDA package obtained in step (1). After stirring and mixing the covered explosive powder for 2 hours, the temperature of the solution system was raised to 90°C by means of oil bath heating, and the water solvent was evaporated under continuous stirring. After a large amount of solvent volatilized (about 1 hour), the resulting mixture slurry was transferred to Thoroughly dry in an oven at 60°C to obtain explosive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com