High-transparency salt-tolerant acrylic thickener and preparation method thereof

An acrylic thickener, high transparency technology, applied in the field of polymer materials, can solve the problems of reduced hydrophilicity of powder products, longer dispersion time, unclear liquid, etc., to achieve good light transmittance and thickening properties, Easy to swell and disperse, and improve the effect of light transmittance deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a high-transparency salt-resistant acrylic acid thickener of the present embodiment comprises the following preparation steps:

[0030] (1) In parts by weight, add 100 parts of acrylic acid monomer, 0.5 part of cross-linking agent pentaerythritol diallyl ether and 300 parts of organic solvent toluene into the reactor, raise the temperature to 55-60 ° C under nitrogen protection, and then drop Add the first initiator azobisisobutyronitrile toluene solution, the amount of azobisisobutyronitrile is 0.03 parts, the time for adding the first initiator is 1h, after the addition of the initiator is completed, the temperature is raised to 65-70°C for heat preservation reaction 3h.

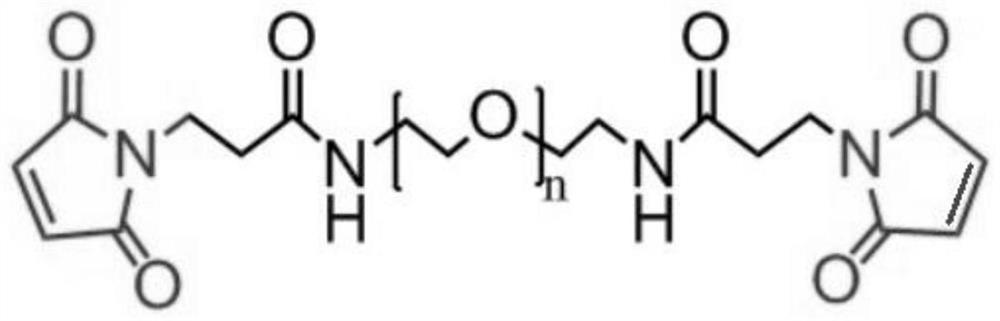

[0031] (2) Add 6 parts of octadecyl methacrylate hydrophobic monomer and 0.6 parts of bismaleimide polyethylene glycol (MAL-PEG-MAL, average molecular weight 10000) to the reaction solution of step (1) Mix evenly, then add 0.01 part of benzoyl peroxide toluene solution at on...

Embodiment 2

[0033] A preparation method of a high-transparency salt-resistant acrylic acid thickener of the present embodiment comprises the following preparation steps:

[0034] (1) In parts by weight, 80 parts of acrylic acid monomers, 20 parts of methacrylic acid monomers, 0.2 parts of crosslinking agent pentaerythritol triallyl ether and 250 parts of organic solvent cyclohexane are added to the reactor, under nitrogen protection Lower the temperature to 55-60°C, then dropwise add the first initiator azobisisobutyrate dimethyl cyclohexane solution, the amount of azobisisobutyronitrile is 0.05 parts, and the first initiator dropping time is 1.5 h, after the initiator is added dropwise, the temperature is raised to 65-70°C and the temperature is kept for 2 hours.

[0035] (2) Add 3 parts of dodecyl methacrylate hydrophobic monomer and 0.3 parts of bismaleimide polyethylene glycol (MAL-PEG-MAL, average molecular weight 2000) to the reaction solution of step (1) Mix evenly, then add cyclo...

Embodiment 3

[0037] A preparation method of a high-transparency salt-resistant acrylic acid thickener of the present embodiment comprises the following preparation steps:

[0038] (1) In parts by weight, add 100 parts of acrylic acid monomer, 0.2 parts of allyl sucrose as a crosslinking agent and 400 parts of organic solvent ethyl acetate into the reactor, raise the temperature to 55-60°C under the protection of nitrogen, and then drop Add the first initiator azobisisoheptanonitrile ethyl acetate solution, the amount of azobisisoheptanonitrile is 0.02 parts, the time for adding the first initiator is 0.5h, and the temperature is raised to 65-70 after the addition of the initiator is completed. ℃ insulation reaction for 4h.

[0039] (2) Add 9 parts of lauryl methacrylate hydrophobic monomer and 0.9 part of bismaleimide polyethylene glycol (MAL-PEG-MAL, average molecular weight 5000) to the reaction solution of step (1) Mix evenly, then add 0.015 parts of ethyl acetate solution containing l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com