Halogen-free flame-retardant thermoplastic polyurethane cable material and preparation method thereof

A thermoplastic polyurethane and cable material technology, applied in the field of cable materials, can solve problems such as deterioration of mechanical properties and flame retardant properties, agglomeration of flame retardants, long storage time, etc., to achieve improved mechanical properties, stable performance, and control of operation and time convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Its preparation method comprises the following steps:

[0036] S1. Preparation of blocked isocyanate prepolymer: polymerize diisocyanate and macromolecular diol at a temperature of 80-120°C, add blocking agent after polymerization, fully react, filter and dry to obtain blocked isocyanate prepolymer , Preheat the blocked isocyanate prepolymer at 45-55°C for 30-50min;

[0037] S2. Drying of raw materials: drying the thermoplastic polyurethane resin, flame retardant, antioxidant and light stabilizer in an oven at 90-110°C until the moisture content is lower than 0.02%;

[0038] S3. Mixing materials: add the preheated blocked isocyanate prepolymer in step S1 and the dried materials in step S2 to the high-speed mixer in sequence according to parts by weight, mix for 3-5 minutes, and mix evenly to obtain a mixed material;

[0039] S4. Extrusion granulation: Extrude the mixture with a twin-screw extruder, the temperature of the twin-screws is 170-190°C, and granulate by cutti...

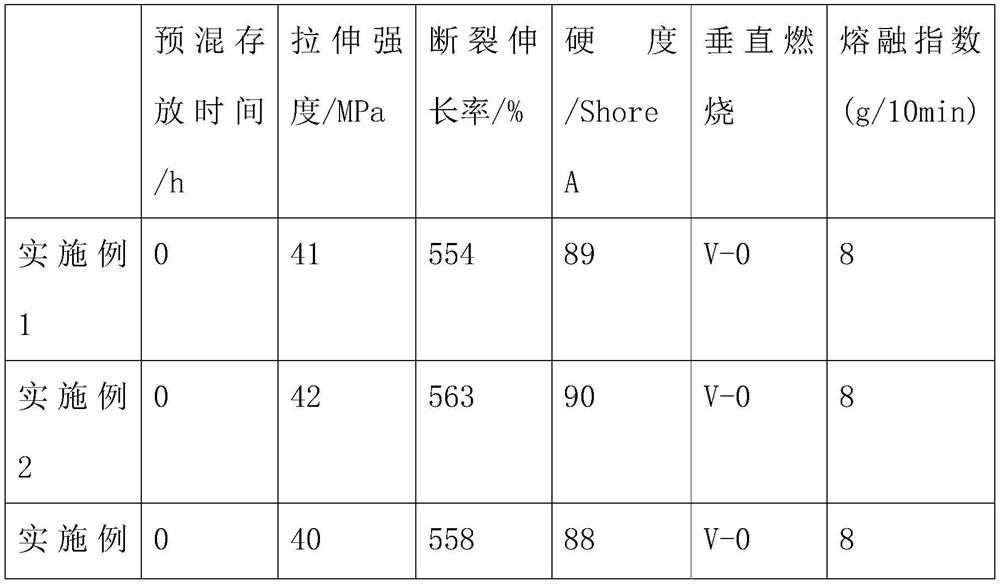

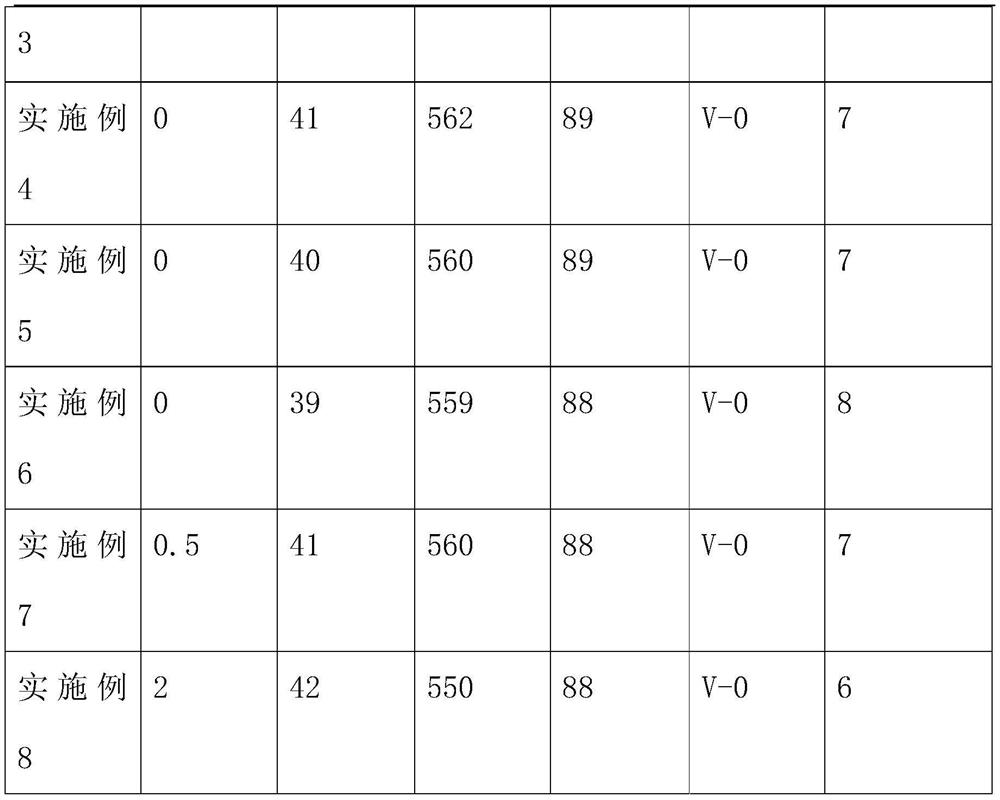

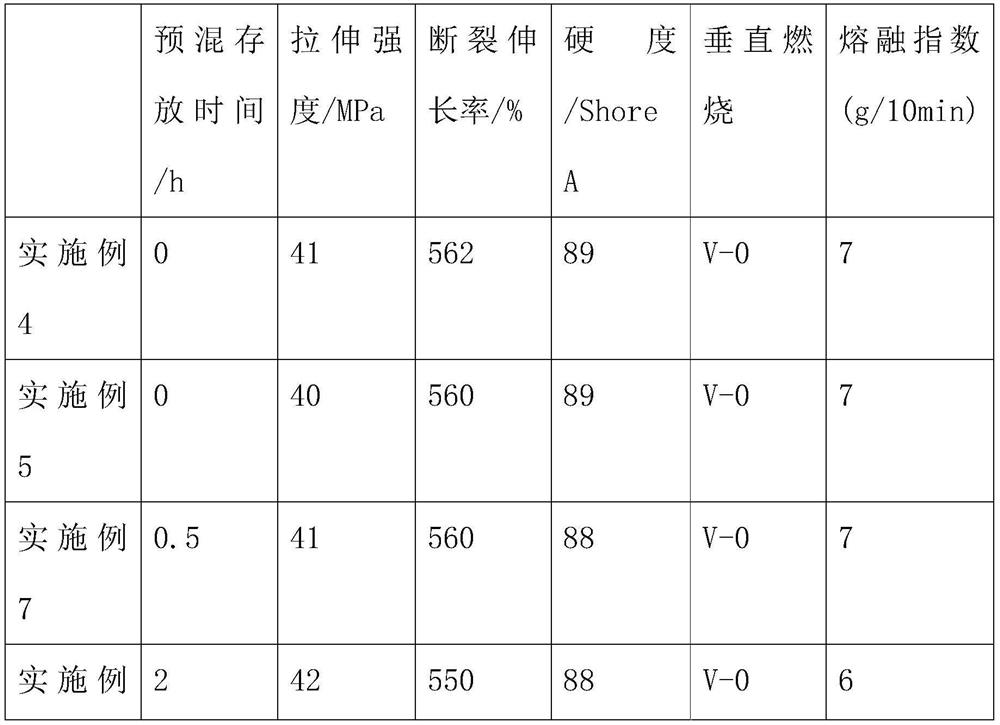

Embodiment 1

[0046] Firstly, the blocked isocyanate prepolymer is prepared by polymerizing 2,2'-diphenylmethane diisocyanate and polyoxypropylene diol at a molar ratio of 1.3:1 at a temperature of 80°C, adding The dibutyltin dilaurate of polymer gross weight 2%, add the phenol that accounts for polymer gross weight 8% wherein to it after polymerization is completed, fully react, obtain the blocked type isocyanate prepolymer of blocking rate 95%, block type isocyanate The prepolymer was preheated at 50°C for 40 minutes.

[0047] Place the raw materials in an oven at 90°C and dry until the moisture content is lower than 0.02%. Weigh 60 parts of thermoplastic polyurethane, 20 parts of aluminum diethylphosphinate, and 7.5 parts of bisphenol A-bis(diphenyl phosphate ), 5 parts of montmorillonite, 0.5 parts of antioxidant 1010, and 0.5 parts of light stabilizer Tinuvin 234 were put into a high-speed mixer for premixing for 3 minutes, and 1 part of preheated blocked isocyanate prepolymer was weig...

Embodiment 2

[0049] Firstly, the blocked isocyanate prepolymer is prepared by polymerizing 2,2'-diphenylmethane diisocyanate and polyoxypropylene diol at a molar ratio of 1.5:1 at a temperature of 100°C, adding The dibutyltin dilaurate of polymer gross weight 1%, adds the phenol that accounts for polymer gross weight 5% wherein to it after polymerization is completed, fully reacts, obtains the blocked type isocyanate prepolymer of sealing rate 92%, will blocked type isocyanate The prepolymer was preheated at 45°C for 50 minutes.

[0050] Place the raw materials in an oven at 100°C and dry until the moisture is lower than 0.02%, weigh 70 parts of thermoplastic polyurethane, 15 parts of aluminum diethylphosphinate, 10 parts of bisphenol A-bis(diphenyl phosphate ), 10 parts of montmorillonite, 1.2 parts of antioxidant 1010, and 0.8 parts of light stabilizer Tinuvin 234 were put into a high-speed mixer for premixing for 3 minutes, and 5 parts of preheated blocked isocyanate prepolymers were we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com