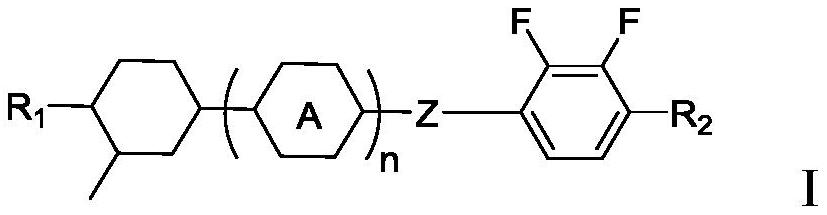

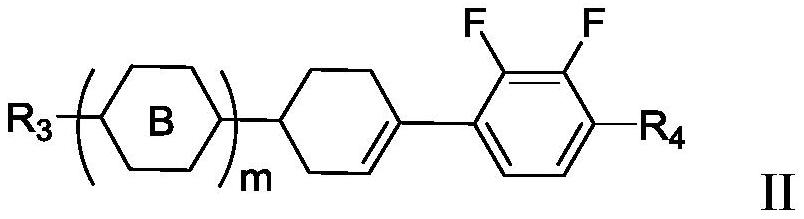

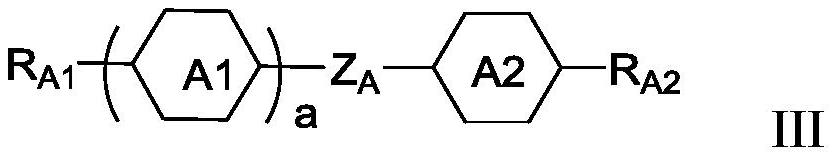

Liquid crystal composition containing substituted cyclohexyl compound and application thereof

A liquid crystal composition and compound technology, which is applied in the field of liquid crystal compositions containing substituted cyclohexyl compounds, negative liquid crystal compounds and their compositions, to achieve the effects of low rotational viscosity, shortened response time, and large elastic constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] Embodiment 1: the synthesis of compound 3MCWO2

[0127] Its specific preparation process is as follows:

[0128]

[0129] (1) Synthesis of 3MC(V)WO2

[0130] Add 31.6g of 2,3-difluorophenetole and 300ml of tetrahydrofuran into the reaction flask, stir, and lower the temperature to -80°C under the protection of nitrogen. Slowly add 90 ml of 2.5M butyllithium / n-hexane solution dropwise, and keep the temperature between -70 and -75°C during the dropwise addition. After the addition of butyllithium was completed, the temperature was kept between -65°C and -75°C under the protection of nitrogen, and stirred for 6 hours. Dissolve 35.0g of 3MCK in 100ml of tetrahydrofuran and add it dropwise. During the dropwise addition, control the temperature between -75°C and -80°C. Control the temperature at -70°C to -75°C and stir for 3 hours. Add 45ml of concentrated hydrochloric acid and 150ml of water into a 1000ml beaker. Under stirring, the reaction solution was slowly poure...

Embodiment 2

[0135] Embodiment 2: the synthesis of compound 3MPWO2

[0136] Concrete synthetic steps are as follows:

[0137]

[0138] (1) Synthesis of 3M(V)P-Br

[0139] Add 2.6 g of magnesium chips, 300 ml of dry tetrahydrofuran (THF), and 1 grain of iodine into the reaction flask, stir, and raise the temperature to 40°C. Slowly add p-dibromobenzene 21g / THF40nl dropwise, after the reaction is initiated, slowly add dropwise, and control the temperature between 50-60°C. After the dropwise addition, the temperature was raised to reflux for 2h. Cool down to room temperature, water system, toluene extraction and separation. Add 1.2 g of p-toluenesulfonic acid to the obtained organic layer, raise the temperature and reflux for water separation for 4 h, cool to room temperature, add water 200 ml toluene 100 to extract and separate layers, and perform conventional post-treatment to obtain 36 g of 3M(V)P-Br oil. GC-MS: 292.1.

[0140] (2) 3M(V)PWO2

[0141] Add 50g 3M(V)P-Br, 48g 2,3-dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com