Composite electrode material and preparation method and application thereof

A composite electrode and composite material technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., to achieve the effect of convenient preparation, high lithium ion conductivity, and improved performance of lithium metal batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] SMA and (R)-(2,2-dimethyl-1,3dioxolan-4-yl)methylamine (DMDOL) were added to DMF at a ratio of 1:2 (MAn unit: DMDOL), Placed in a 60°C oil bath for 24 hours under vacuum, the product was recrystallized with toluene and the filtrate was dried to obtain (R)-(2,2-dimethyl-1,3dioxolane-4 -yl) methylamine pendant styrene ring-opened maleic anhydride (SMA-DMDOL), product molecular weight M n =4319, M w =7769.

[0040]The prepared SMA-DMDOL was dissolved in anhydrous DMF, configured into a 5 M solution, and the thick lithium sheet was soaked in the solution for 30 minutes, then taken out and dried in a vacuum oven to obtain (R)- (2,2-Dimethyl-1,3-dioxolan-4-yl)methylamine pendant polystyrene ring-opened maleic anhydride interfacially modified lithium metal anode with artificial solid electrolyte.

[0041] All the above operations were performed in a glove box.

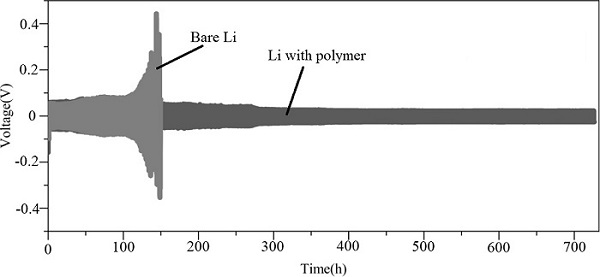

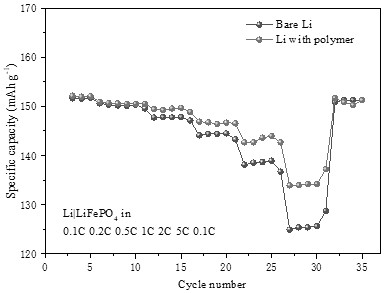

[0042] The modified lithium metal anode was mixed with commercially pure lithium in the electrolyte (1M LiPF 6 ...

Embodiment 2

[0045] This embodiment carries out similar parallel test with embodiment 1, and the difference is that lithium metal is changed into 84Li-B alloy, and other preparation methods are exactly the same as embodiment 1, obtains containing (R)-(2,2-dimethyl -1,3-dioxolan-4-yl)methylamine pendant polystyrene ring-opened maleic anhydride artificial solid electrolyte modified lithium boron alloy anode.

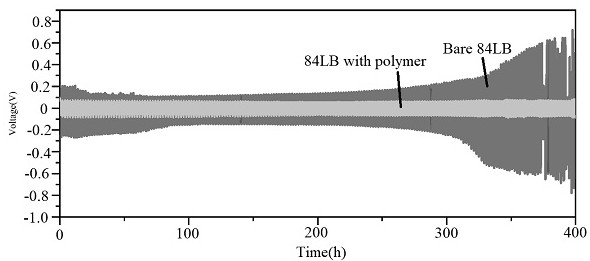

[0046] The modified lithium-boron alloy negative electrode and the bare lithium-boron alloy negative electrode were mixed in the electrolyte (1M LiPF 6 , EC:EMC:FEC=3:7:1 (v / v)) for electrochemical tests at 1 mA / cm 2 The current density of 1 mAh / cm 2 Under the condition of specific area specific capacity, the symmetrical battery can reach 400 hours of long-term cycle and still maintain a low polarization voltage (less than 50 mV). Test results such as figure 2 shown.

Embodiment 3

[0048] This embodiment and embodiment 1 carry out similar parallel test, the difference is that lithium metal is changed to Li-B-Ag alloy, and other preparation methods are exactly the same as embodiment 1, and the obtained compound containing (R)-(2,2-di Methyl-1,3-dioxolan-4-yl)methylamine pendant polystyrene ring-opened maleic anhydride interfacially modified Li-B-Ag alloy anode with artificial solid electrolyte.

[0049] The modified Li-B-Ag alloy negative electrode and the bare Li-B-Ag alloy negative electrode were mixed in the electrolyte (1M LiPF 6 , EC:EMC:FEC=3:7:1 (v / v)) for electrochemical tests, at 1 mA / cm 2 The current density of 10 mAh / cm 2 Under the condition of specific area specific capacity, the symmetric battery can reach 800 hours of long-term cycle and still maintain a low polarization voltage (less than 40 mV). Test results such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com