Method for preparing sub-nano silicon-carbon composite material by liquid phase method

A silicon-carbon composite material and sub-nanometer technology, applied in nano-carbon, silicon compounds, nanotechnology and other directions, can solve the problem that it is difficult to easily obtain a sub-nano-sized silicon-carbon composite material, and the growth and deposition of silane gas into silicon particles cannot be precisely controlled. , it is difficult to realize the preparation of sub-nano-sized silicon materials, etc., to achieve the effect of improving high energy density, easy to enlarge the method, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

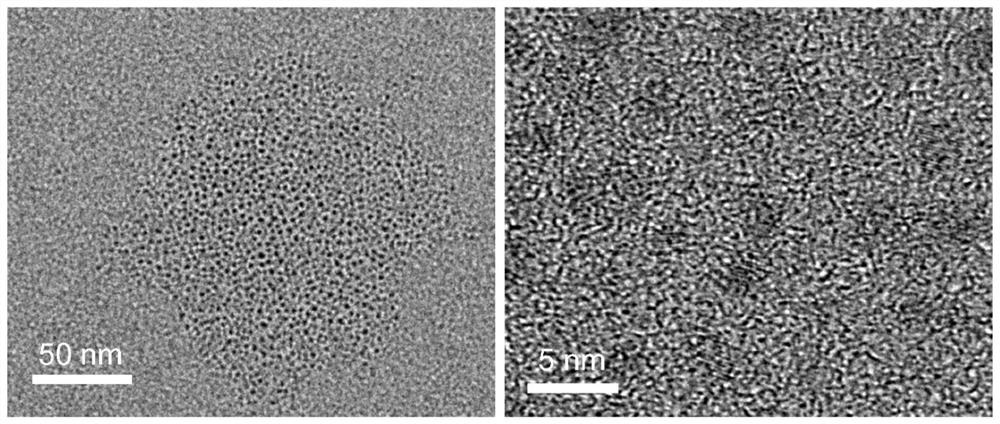

Image

Examples

Embodiment 1

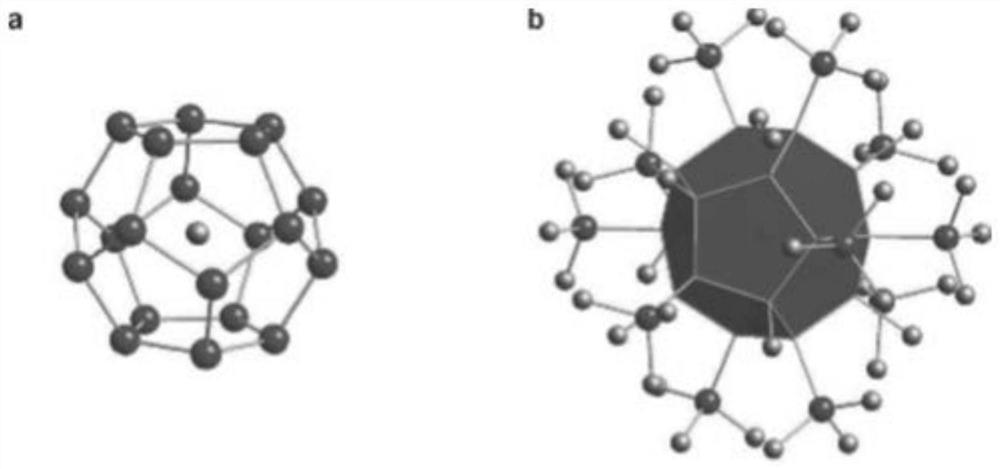

[0025] Step (1): HSiCl 3 and ethylenediamine were dissolved in acetonitrile in a mass ratio of 5:1, and stirred at room temperature for 10 hours to obtain a yellow solution;

[0026] Step (2): Mix and react the yellow solution in step (1) with 0.1 mol of amylmagnesium bromide, stir at room temperature for 2 hours, and purify to obtain a mixed solution of organic group-modified silicon clusters;

[0027] Step (3): The mixed solution in step (2) was pumped dry under reduced pressure to obtain a yellow solid, which was placed in a tube furnace and heat-treated at 500°C for 2 hours under the protection of flowing high-purity argon. After cooling, The subnano-silicon-carbon composite material was prepared.

Embodiment 2

[0029] Step (1): HSiCl 3 and ethylenediamine were dissolved in tetrahydrofuran in a mass ratio of 5:1, and stirred at room temperature for 10 hours to obtain a yellow solution;

[0030] Step (2): Mix and react the yellow solution in step (1) with 0.1 mol of amylmagnesium bromide, stir at room temperature for 2 hours, and purify to obtain a mixed solution of organic group-modified silicon clusters;

[0031] Step (3): The mixed solution in step (2) was pumped dry under reduced pressure to obtain a yellow solid, which was placed in a tube furnace and heat-treated at 500°C for 2 hours under the protection of flowing high-purity argon. After cooling, The subnano-silicon-carbon composite material was prepared.

Embodiment 3

[0033] Step (1): Si 2 Cl 6 and ethylenediamine were dissolved in acetonitrile in a mass ratio of 5:1, and stirred at room temperature for 10 hours to obtain a yellow solution;

[0034] Step (2): Mix and react the yellow solution in step (1) with 0.1 mol of amylmagnesium bromide, stir at room temperature for 2 hours, and purify to obtain a mixed solution of organic group-modified silicon clusters;

[0035] Step (3): The mixed solution in step (2) was pumped dry under reduced pressure to obtain a yellow solid, which was placed in a tube furnace and heat-treated at 500°C for 2 hours under the protection of flowing high-purity argon. After cooling, The subnano-silicon-carbon composite material was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com