Efficient fluorine removal agent as well as preparation method and use method thereof

A high-efficiency defluoridation agent, applied in the field of high-efficiency defluoridation agent and its preparation, can solve the problems of frequent regeneration, difficult water discharge, poor treatment effect, etc., to reduce the cost of solid waste treatment, high chemical purity, and defluoridation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

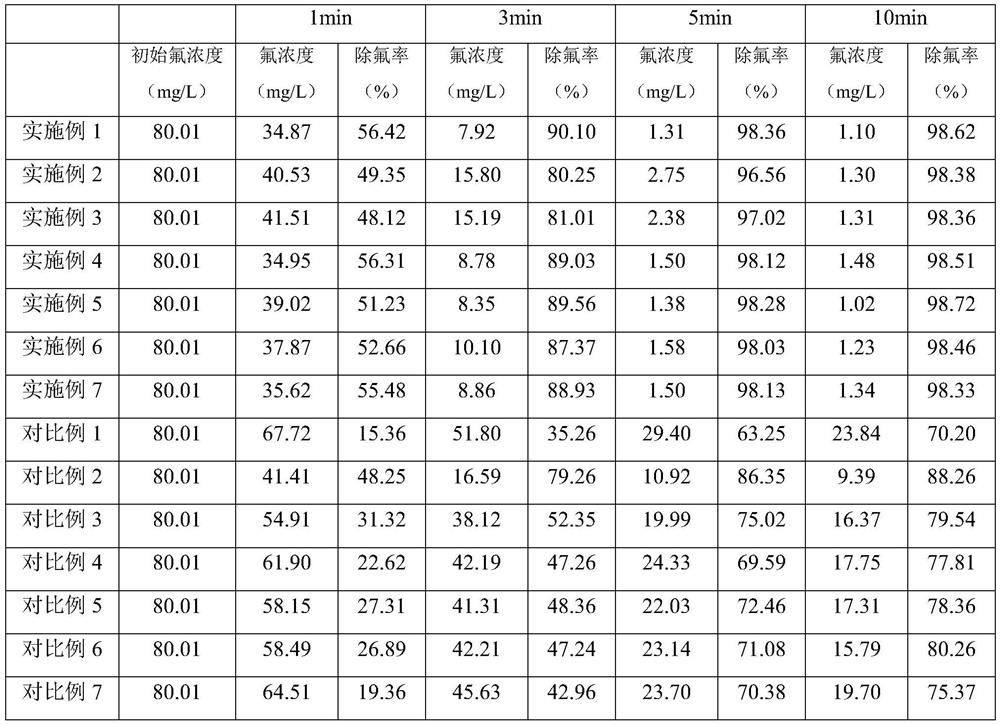

Examples

Embodiment 1

[0029] According to the following mass parts batching:

[0030] 60 parts of aluminum sulfate, 20 parts of polyaluminum chloride, 11 parts of polyaluminum ferric chloride, 8 parts of calcium chloride, 8 parts of ferric chloride and 3 parts of flocculant.

[0031] It is prepared as a high-efficiency fluoride removal agent according to the following steps:

[0032] Fully mix and stir the aluminum sulfate, polyaluminum chloride, polyaluminum ferric chloride, calcium chloride and ferric chloride, and grind them through an 80-mesh sieve;

[0033] Continue to add flocculant and mix well.

[0034] Preferably, the rate of mixing and stirring aluminum sulfate, polyaluminum chloride, polyaluminum ferric chloride, calcium chloride and ferric chloride is 320 rpm, and the stirring time is 2.5 h.

[0035] Preferably, the speed of adding flocculant and stirring is 320rpm, and the stirring time is 2.5h.

[0036] The method of use is:

[0037] Adjust the pH of the wastewater to be treated t...

Embodiment 2

[0042] Other operating conditions are consistent with embodiment 1, according to following mass parts batching:

[0043] 50 parts of aluminum sulfate, 30 parts of polyaluminum chloride, 6 parts of polyaluminum ferric chloride, 11 parts of calcium chloride, 4 parts of ferric chloride and 5 parts of flocculant.

Embodiment 3

[0045] Other operating conditions are consistent with embodiment 1, according to following mass parts batching:

[0046] 70 parts of aluminum sulfate, 10 parts of polyaluminum chloride, 16 parts of polyaluminum ferric chloride, 4 parts of calcium chloride, 11 parts of ferric chloride and 1 part of flocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com