Microporous polymer diaphragm for secondary lithium cell and its preparation method

A technology of microporous polymers and secondary lithium batteries, which is applied to battery components, circuits, electrical components, etc., can solve the problem of unsuitable secondary lithium battery manufacturing, no self-sealing mechanism, and mechanical strength of microporous inverted membranes. Poor problems, to achieve the effect of controllable aperture size, simple manufacturing process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

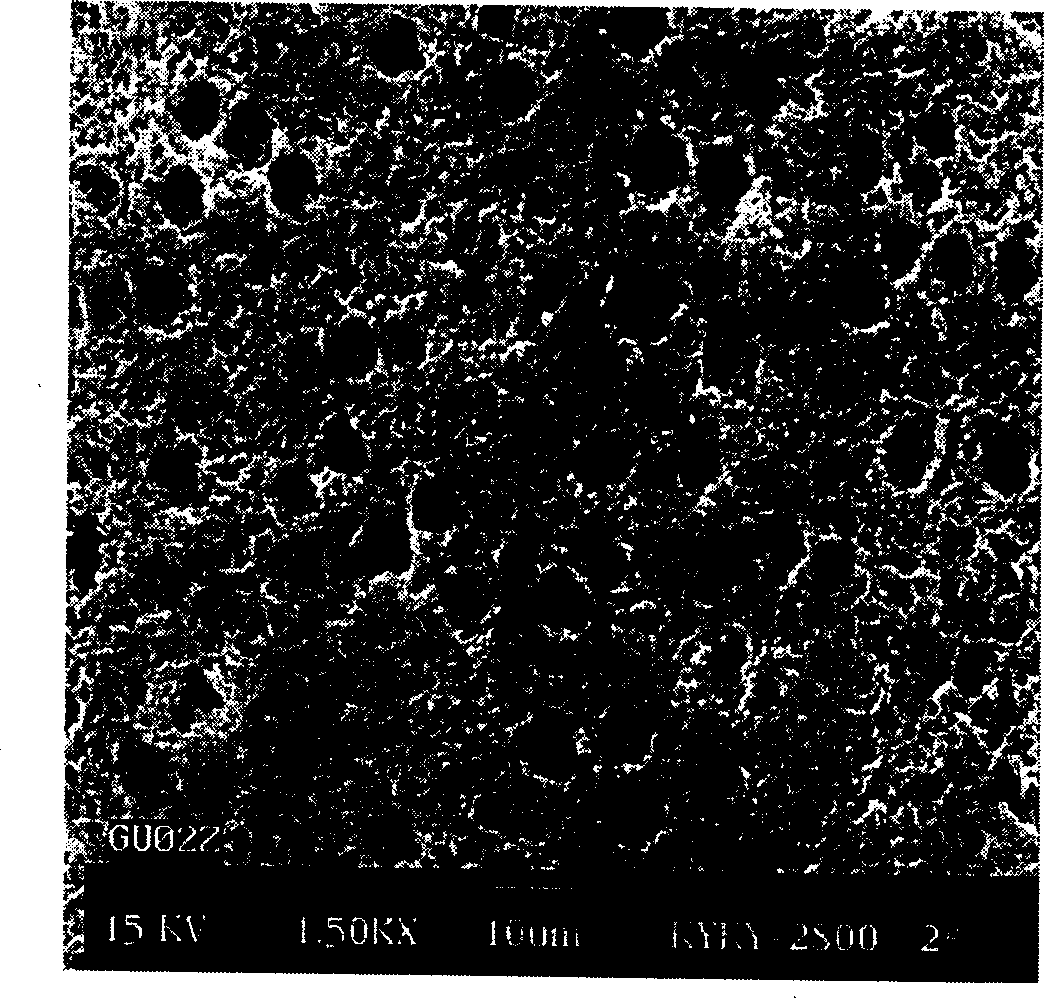

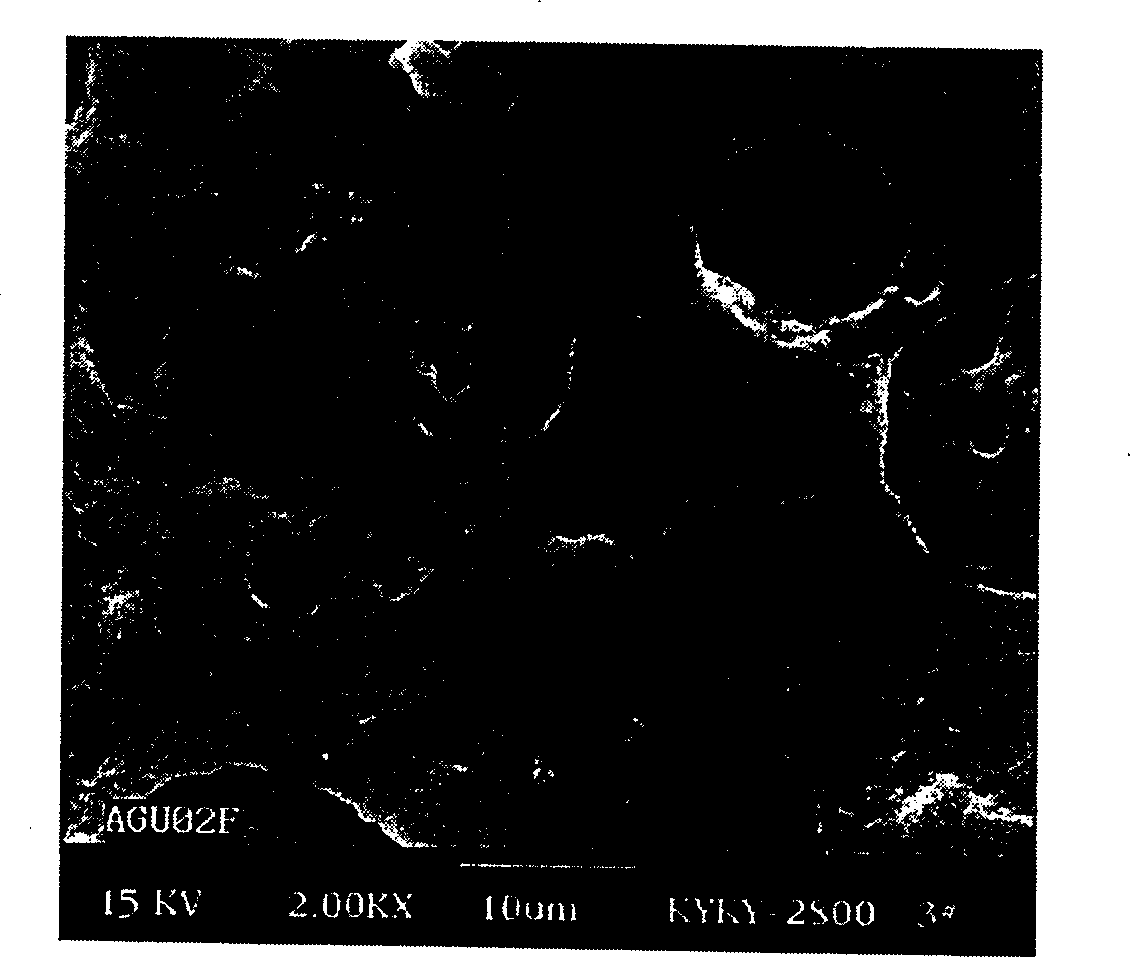

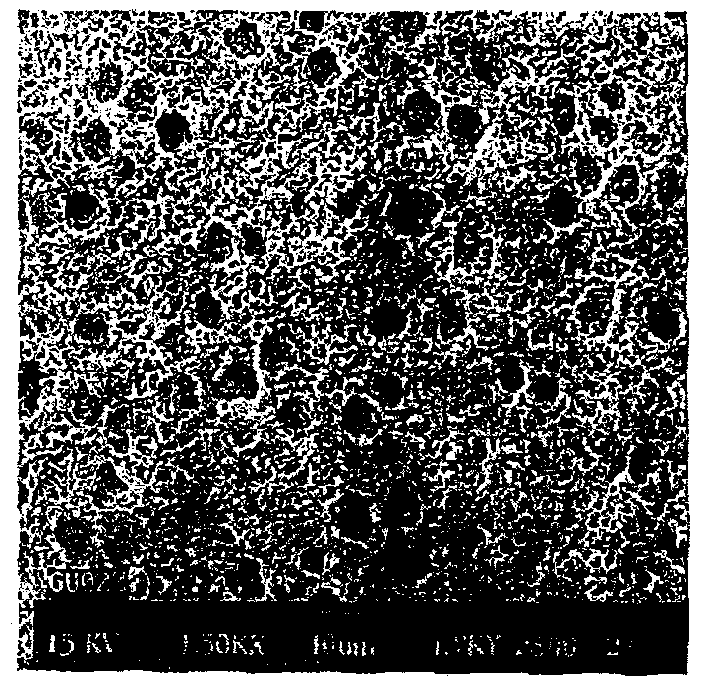

[0044] Polyvinylidene fluoride (Kynar2851 type PVDF), 618 epoxy resin, N, N-dimethylbenzylamine, acetone, glycerol (glycerol) are mixed in a ratio of 10:8:1.2:160:7 by weight, Heat and dissolve to form a uniform and transparent solution as a casting solution, apply it on a clean glass substrate, leave it at room temperature for 5 minutes, then immerse it in a mixture of acetone and water with a volume ratio of 1:3 for 5 minutes at room temperature, take it out Then immerse in a mixture of acetone and water at a volume ratio of 1:3 at 0° C. for 25 minutes, and place in a vacuum oven at 40° C. for 36 hours to dry off residual solvents and non-solvents. SEM images of the diaphragm are shown in figure 1 , the electron micrograph of micropore closing after heating at 160℃ is shown in figure 2 .

[0045] Cut the dried membrane to 1.8cm 2 The disc, with metal lithium foil as the cathode and MCMB as the anode, is assembled with the separator into a button-type experimental battery...

Embodiment 2

[0048] Mix polyvinylidene fluoride (Kynar2851 type PVDF), 618 epoxy resin, dicyandiamide, acetone, glycerol (glycerol) in a weight ratio of 10:8:0.5:160:7, heat and dissolve to form a uniform and transparent The solution is used as a casting solution, coated on a clean glass substrate, left at room temperature for 5 minutes, then immersed in a mixture of acetone and water with a volume ratio of 1:3 at room temperature for 5 minutes, and then immersed in acetone at 0 °C after taking it out. and water in a mixed solution with a volume ratio of 1:3 for 25 minutes, and placed in an oven at 40° C. for 36 hours to dry off residual solvents and non-solvents.

[0049] The preparation of the anode and the assembly and testing methods of the battery are the same as in Example 1, and the charging and discharging data are listed in Table 1.

Embodiment 3

[0051] Mix polyvinylidene fluoride (Kynar2851 type PVDF), 618 epoxy resin, polyethylene polyamine, acetone, glycerin (glycerin) in a weight ratio of 10:8:1.5:160:7, heat and dissolve to form a uniform The solution is used as a casting solution, taken out and coated on a clean glass substrate, left at room temperature for 5 minutes, then immersed in a mixture of acetone and water with a volume ratio of 1:3 at room temperature for 5 minutes, taken out and then immersed in a 0°C The mixture of acetone and water with a volume ratio of 1:3 was placed for 25 minutes, and placed in an oven at 40° C. for 10 hours to dry off residual solvents and non-solvents.

[0052] The preparation of the anode and the assembly and testing methods of the battery are the same as in Example 1, and the charging and discharging data are listed in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap