Preparation method of high-current-density water electrolysis hydrogen production catalyst

A catalyst, high current technology, applied in the electrolysis process, electrolysis components, electrodes and other directions, can solve the problems of low electrolysis efficiency, high energy consumption, low catalyst activity, etc., to improve the activity and efficiency of hydrogen production, easy to control the dispersion, The effect of reducing the energy consumption of hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0038] This embodiment provides a preparation method containing Co and carbon nanotube catalysts, the main steps are:

[0039] (1) 5g of melamine, 0.5g of carbon nanotubes and 4.9g of cobalt nitrate were ball milled (600rpm / 6h, the mass ratio of zirconia ceramic balls to the mixture was 5:1.

[0040] (2) The ball-milled mixture was placed in a crucible and subjected to pyrolysis for 4 hours at 550°C with nitrogen gas flow, and the obtained sample 1 was used to evaluate the reaction performance of hydrogen production by electrolysis of water.

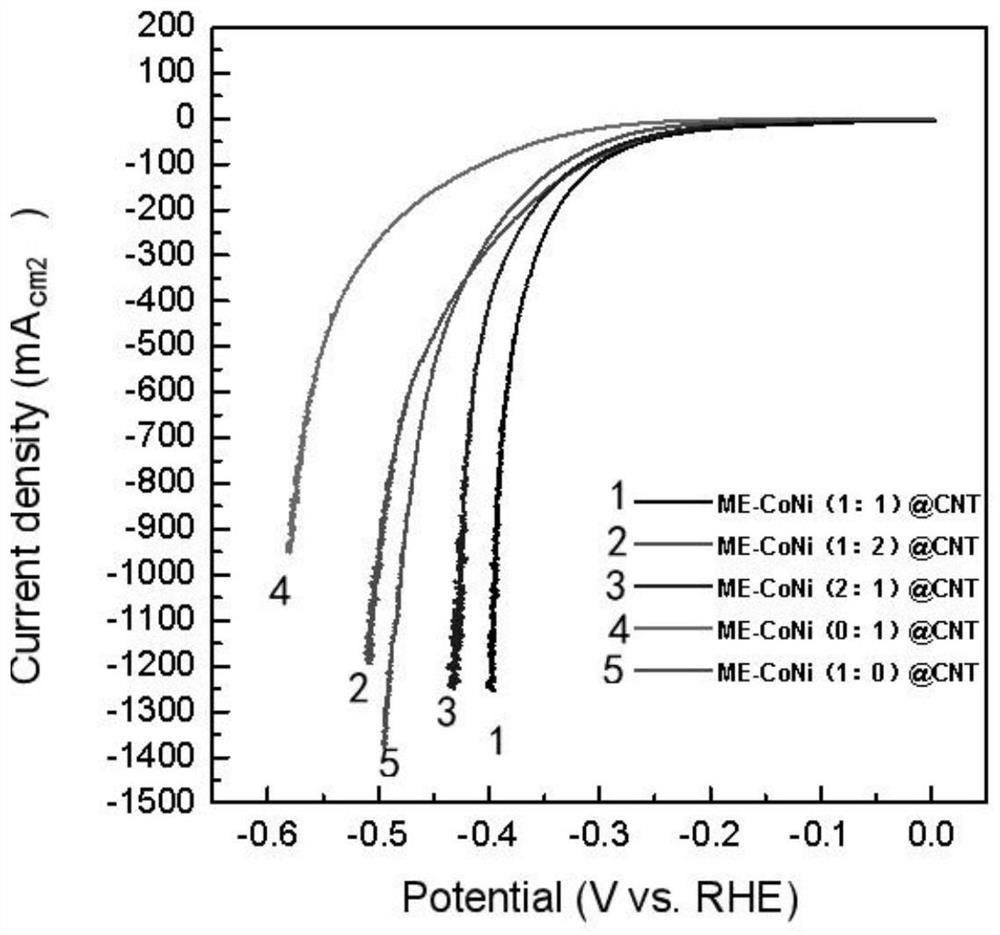

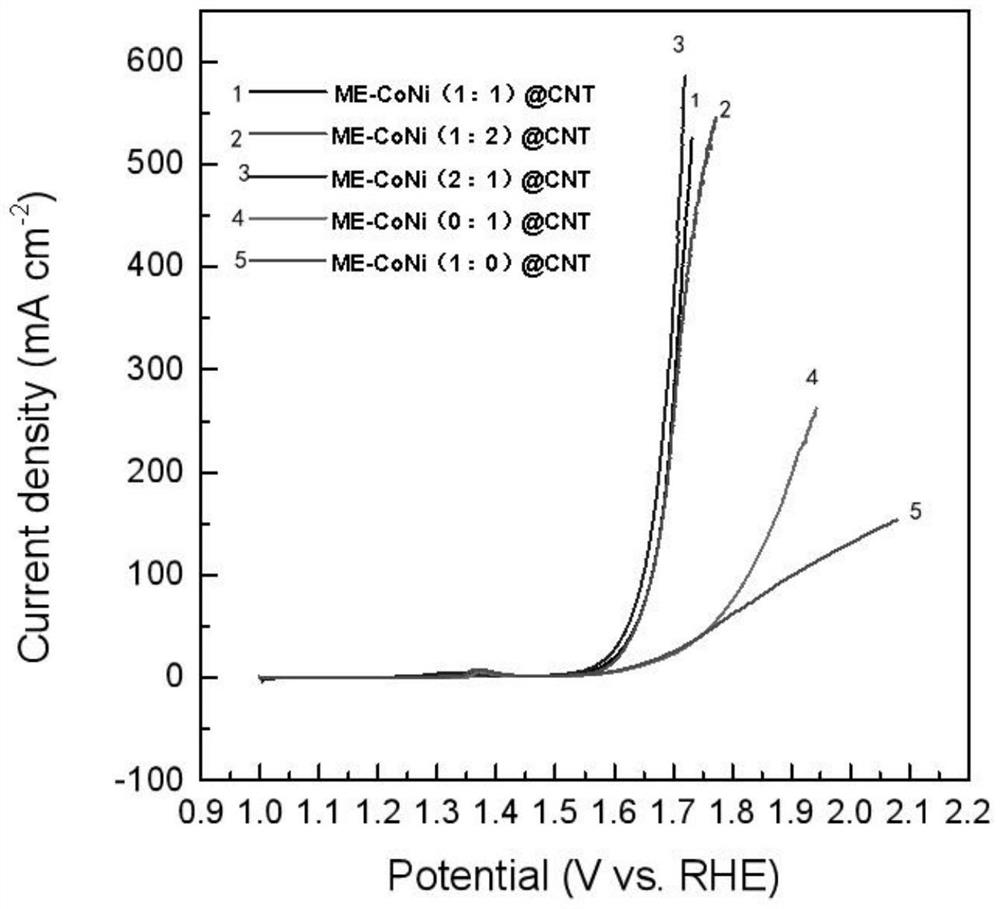

[0041] (3) It is necessary to apply an overvoltage of 0.48V to achieve 1000mA / cm2; at an overvoltage of 0.3V, the normalized hydrogen production rate reaches 0.5mL / min·g.

Embodiment 2

[0043] The present embodiment provides a kind of preparation containing Ni and carbon nanotube catalyst:

[0044] (1) 5 g of melamine, 0.5 g of carbon nanotubes and 4.9 g of nickel nitrate were ball milled (600 rpm / 6 h, the mass ratio of zirconia ceramic balls to the mixture was 5:1).

[0045] (2) The ball-milled mixture was placed in a crucible and subjected to pyrolysis for 4 hours at 550°C with nitrogen gas flow, and the obtained sample 2 was used for the evaluation of the reaction performance of hydrogen production by electrolysis of water.

[0046] (3) Achieve 1000mA / cm 2 An overvoltage of 0.65V needs to be applied; at an overvoltage of 0.3V, the normalized hydrogen production rate reaches 0.2mL / min·g.

Embodiment 3

[0048] This embodiment provides a kind of preparation method containing Co, Ni and carbon nanotube catalyst, main steps:

[0049](1) 5g melamine, 0.5g carbon nanotubes, 2.45g cobalt nitrate and 2.45g nickel nitrate were ball milled (600rpm / 6h, the mass ratio of zirconia ceramic balls to the mixture was 5:1.

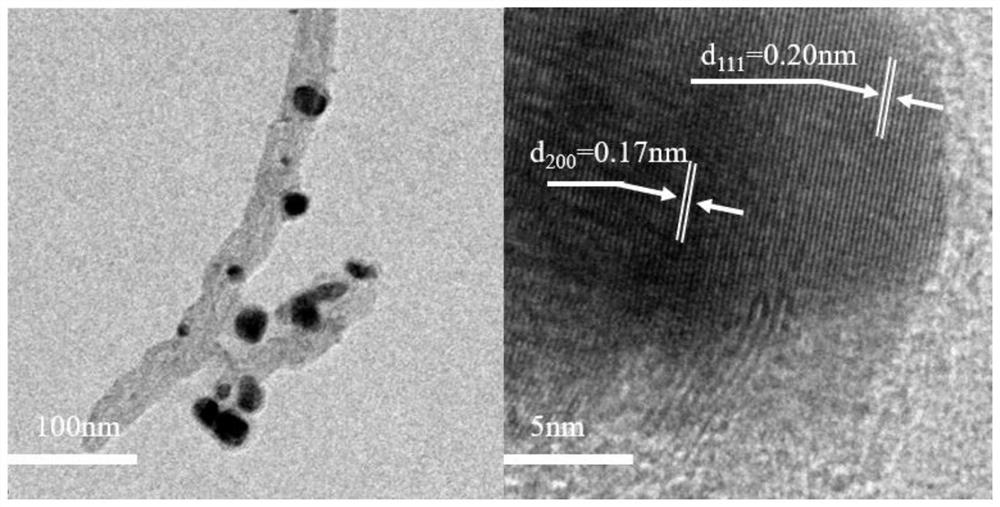

[0050] (2) The ball-milled mixture was placed in a crucible and subjected to pyrolysis for 4 hours at 550°C with nitrogen gas flow, and the obtained sample 3 was used to evaluate the reaction performance of hydrogen production by electrolysis of water. Example 3 sample (ME-Co / Ni(1:1)@CNT electron microscope image, see image 3 .

[0051] (3) Achieve 1000mA / cm 2 An overvoltage of 0.39V needs to be applied; at an overvoltage of 0.3V, the normalized hydrogen production rate reaches 6.5mL / min·g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com