Electrolyte for battery and battery using electrolyte

An electrolyte and battery technology, applied to secondary batteries, circuits, electrical components, etc., can solve the problems of increased heat generation of batteries, failure to improve battery performance of ternary lithium batteries, increase battery internal resistance, etc., to improve utilization efficiency , Improve antioxidant capacity, inhibit oxidation decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of lithium electronic electrolyte, comprising the steps of:

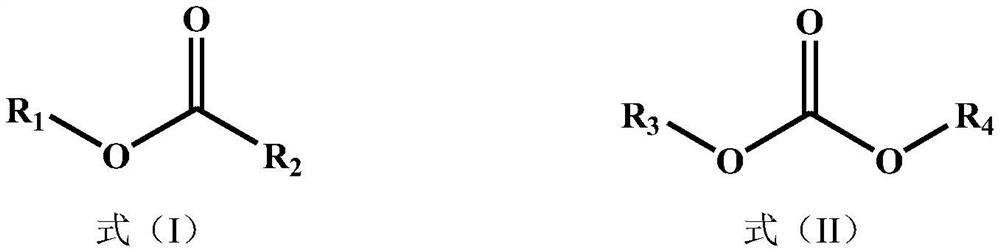

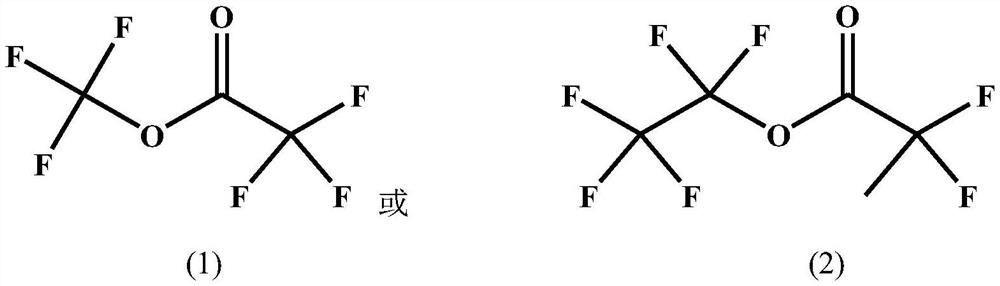

[0038] In the glove box, ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) were mixed according to the mass ratio of 3:2:5, and then 6% mass fraction was added to the mixed solvent The fluoroester compound (1); then add 1.1M lithium hexafluorophosphate to dissolve. After that, 1% vinylene carbonate (VC) and 0.8% lithium difluorophosphate (LiPO 2 f 2 ), 1% vinyl sulfate (DTD), plus 0.5% trimethyl silicon carbonate compound (5).

[0039] Inject the prepared lithium-ion battery electrolyte into the fully dried 4.45V LiNi 0.6 co 0.2 mn 0.2 o 2 / Graphite soft-pack battery, after shelving at 45°C, high-temperature fixture formation, and secondary sealing, the battery performance test was carried out to obtain the battery used in Example 1.

Embodiment 2-32

[0045] Except that the fluorinated ester compound solvent and the silicon trimethylcarbonate compound were added as shown in Table 1, the others were the same as in Example 1. The electrolyte formulations of each embodiment and comparative example are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com