Preparation method of non-fried roasted pickled Chinese cabbage crisp chips

A non-fried and sauerkraut technology, which is applied in the field of preparation of non-fried grilled sauerkraut crisps, can solve the problems of waste of resources, low added value, and low degree of comprehensive utilization, so as to meet diversified needs, promote value-added efficiency, Increase the effect of marketing sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

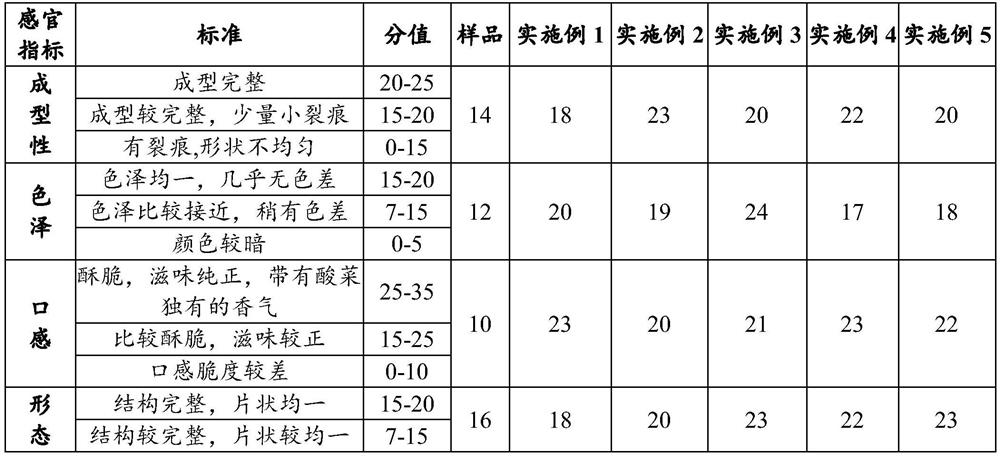

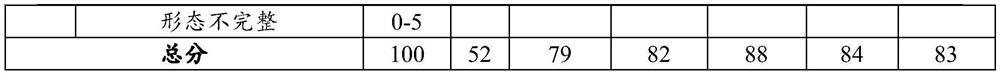

Examples

Embodiment 1

[0032] A No-Fry Baked Sauerkraut Crisp:

[0033] (1) Deacidification: hang 1000g of better quality, bright color, non-rotten sauerkraut sauerkraut in a rotary cleaning and desalination machine, and spray and clean it with a high pressure 200MPa for 60min under the condition of 10r / min; cut the sauerkraut after cleaning Cut into 2-3mm uniform sauerkraut shreds, then place the sauerkraut shreds in the washing machine for air bubble cleaning, remove and drain, and set aside;

[0034] (2) Seasoning and marinating:

[0035] 1) Prepare pork seasoning paste: preheat the reaction vessel to 100°C, add 30ml of soybean oil, 10g of sucrose, and 4g of caramel coloring to raise the temperature to 110°C, then add 1000g of pork fat into the reaction vessel and heat until the surface becomes caramelized, add Water 2500g, papain 2g, D-erythorbic acid 0.6g, raise the temperature to 130°C and heat for 120min, then lower the temperature to 45°C, add starch 3g, agar 6.5-8g, sodium chloride 2-3g in...

Embodiment 2

[0043] A No-Fry Baked Sauerkraut Crisp:

[0044] (1) Deacidification: Deacidification: hang the sauerkraut in a rotary cleaning and desalting machine, and spray and wash it with a high pressure 200MPa for 30min under the condition of 10r / min; cut the sauerkraut after cleaning into 2-3mm sauerkraut filaments. Carry out air bubble cleaning in the washing machine for 30 minutes, remove and drain, and set aside;

[0045] (2) Sauerkraut seasoning:

[0046] 1) Prepare pork seasoning paste: Preheat the reaction vessel to 100°C, add 50ml of soybean oil, 10g of sucrose, and 4g of caramel coloring to raise the temperature to 120°C, then add 1,000g of pork fat into the reaction vessel and heat until the surface becomes caramelized, add Water 2500g, papain 2g, D-erythorbic acid 0.6g, raise the temperature to 150°C and heat for 120min, then lower the temperature to 55°C, add starch 3g, agar 6.5-8g, sodium chloride 3g, corn Sodium Amino Acid 1.5g, Meat Essence 5g, Red Yeast Rice 3.5g, Min...

Embodiment 3

[0053] Embodiment 3, the difference between this embodiment and Embodiment 1 is that

[0054] In the processing of step (3), choose to use an air fryer and bake at 180° C. for 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com