Freeze-dried powder coated nut meat and preparation method thereof

A technology of freeze-dried powder and nut kernels, which is applied in the field of food processing, can solve problems such as insufficient freeze-dried fruit powder sterilization treatment, freeze-dried fruit powder microorganisms exceeding the standard, freeze-dried fruit powder flavor loss, etc., to achieve storage stability, The effect of enriching the taste level and preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

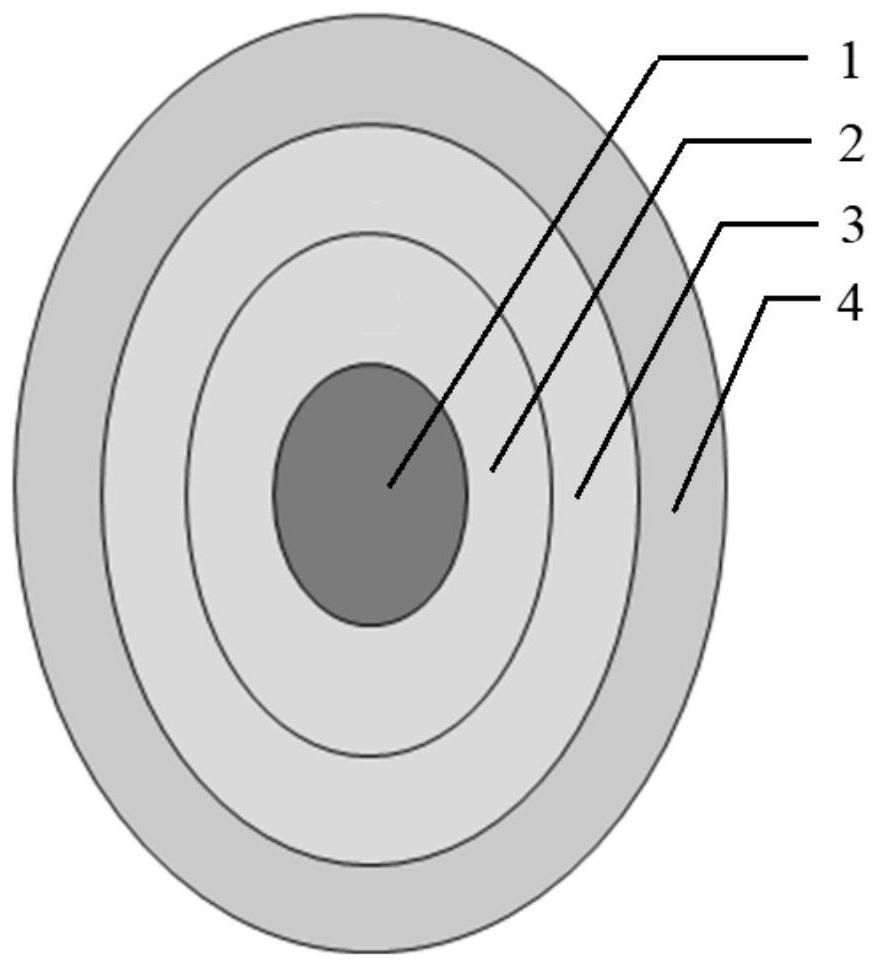

Image

Examples

Embodiment 1

[0044] A kind of preparation method of freeze-dried powder coated nut kernel of the present embodiment comprises the following steps:

[0045] Before preparing the oil layer, the cashew kernels are baked and dried at 90-100° C. for 1-2 hours until the moisture content in the cashew kernels is 2-3%. The roasting process can make the cashew kernels crispy, and can also prevent moisture from migrating into the fat layer when the subsequent puffed layer is baked, destroying the adhesion of the fat layer.

[0046] Preparation of the oil-powder mixture: mix the melted cocoa butter and cheese berry powder (freeze-dried strawberry powder, cheese powder and powdered sugar) in a ratio of 10:1 to 8:1 to prepare the oil-powder mixture. The preparation of the oil-powder mixture can avoid the volatilization of flavor substances caused by the loss of baking water, greatly retain the strawberry flavor, and at the same time avoid the flavor fault after the pulp burst.

[0047] Grease layer pr...

Embodiment 2

[0053] A kind of preparation method of freeze-dried powder coating nut kernel of the present embodiment is basically the same as embodiment 1, the difference is:

[0054] Mix the melted cocoa butter with Zhizhi berry mixed powder (freeze-dried strawberry powder, cheese powder and powdered sugar) according to the ratio of 8:1;

[0055] In the oil layer, take the oil-powder mixture and mix evenly with the roasted cashew kernels (the ratio of cashew kernels to oil-powder mixture is 5:1);

[0056] In the polishing layer, the ratio of cashew kernels to polishing liquid is 10:1;

[0057] In the expanded layer, the mass ratio of wheat flour, deformed starch and glutinous rice flour is 20:20:1;

[0058] The Zhizhi berry cashew kernels (freeze-dried powder-coated nut kernels) prepared in this example maintain a complete shape; the shelf life is 8 months, and the strawberry flavor is strong and pure; Dense, but hard on the outside.

Embodiment 3

[0060] A kind of preparation method of freeze-dried powder coating nut kernel of the present embodiment is basically the same as embodiment 1, the difference is:

[0061] Mix the melted cocoa butter with Zhizhi berry mixed powder (freeze-dried strawberry powder, cheese powder and powdered sugar) according to the ratio of 9:1;

[0062] In the oil layer, take the oil-powder mixture and mix evenly with the roasted cashew kernels (the ratio of cashew kernels to oil-powder mixture is 4.5:1);

[0063] In the polishing layer, the ratio of cashew kernels to polishing liquid is 15:1;

[0064] In the puffed layer, the mass ratio of wheat flour, modified starch and glutinous rice flour is 30:30:1~20:20:1

[0065] The Zhizhi berry cashew kernel (freeze-dried powder coated nut kernel) prepared in this example maintains a complete shape; the shelf life is 8 months; the strawberry flavor is rich and pure; the inner layer of the product has a dense mouthfeel and the outer layer is crispy , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com