Chlorine-containing organic matter combustion catalyst with high HCl selectivity and preparation method thereof

A combustion catalyst, selective technology, applied in combustion methods, physical/chemical process catalysts, chemical instruments and methods, etc., to inhibit the formation of polychlorinated products and avoid secondary pollutants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Weigh 2.53g of ammonium metavanadate, dissolve it in ethanolamine aqueous solution, heat to dissolve; weigh 10gTiO 2 , mixed it into a ball mill jar, ball milled it at 500 rpm for 30 minutes, then coated it on the surface of the monolithic honeycomb ceramics, and dried it overnight at 100°C; then, fired it at 600°C for 4 hours to prepare Obtain A; then, impregnate Ru solution on the surface of A, dry at 100°C for 20 hours; bake at 500°C for 4 hours to obtain oxidation state catalyst B; pass oxidation state catalyst B through 10% H 2 -90%N 2 Under the atmosphere, reduce at 450°C for 2 hours to obtain the finished catalyst 0.01%Ru / 3%V-27%TiO 2 / whole honeycomb.

Embodiment 2

[0016] 10gTiO 2 , add 15g of water, make a slurry by ball milling, apply it on the surface of the whole honeycomb, dry it at 120°C, and dry it overnight; bake it at 550°C for 4 hours to make A; then impregnate the surface of A with a mixture of Ru and chromium nitrate Precursor salt solution, dried at 100°C for 20 hours; roasted at 500°C for 4 hours to obtain catalyst B in oxidation state; reduced catalyst B in oxidation state in hydrazine hydrate solution to obtain finished catalyst 0.01% Ru-10 %Cr / 20%TiO 2 / whole honeycomb.

Embodiment 3

[0018] Add 10g of CeZrOx and 15g of water, and make a slurry by ball milling, apply it on the surface of the whole honeycomb, and dry it at 140°C for 10 hours; at 700°C, bake it for 3 hours to prepare A; then, Immerse the precursor salt solution of ammonium metavanadate and chromium nitrate on the surface of A, dry at 100°C for 10 hours; bake at 500°C for 4 hours to prepare B; then impregnate the Ru precursor solution on the surface of B, Dry at 80°C for 24 hours; roast at 500°C for 3 hours to obtain catalyst C in oxidation state; pass catalyst C in oxidation state through 10% H 2 -90%N 2 Reduction, the finished catalyst is prepared 0.02%Ru / 5%V-5%Cr / 25%CeZrOx / integral honeycomb.

[0019] Catalyst evaluation conditions:

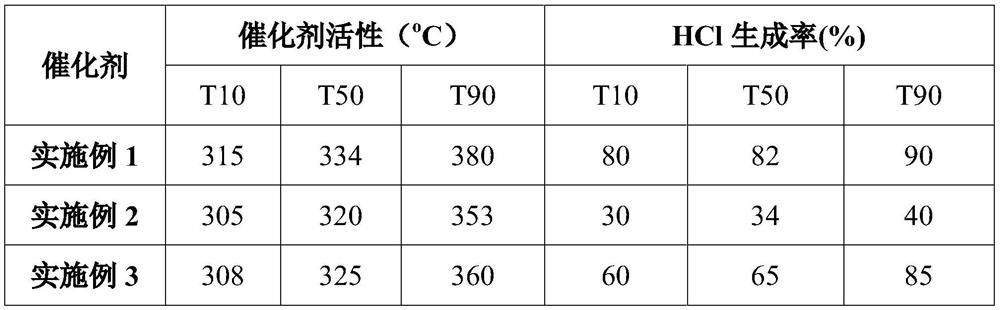

[0020] Activity evaluation conditions: 1000ppm chlorobenzene, air as balance gas, GHSV=20000h -1 , the loading amount of the catalyst is 1ml, and the results are shown in the table below.

[0021] The following table compares the performance of different c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com