Clean production process in field of chemical production

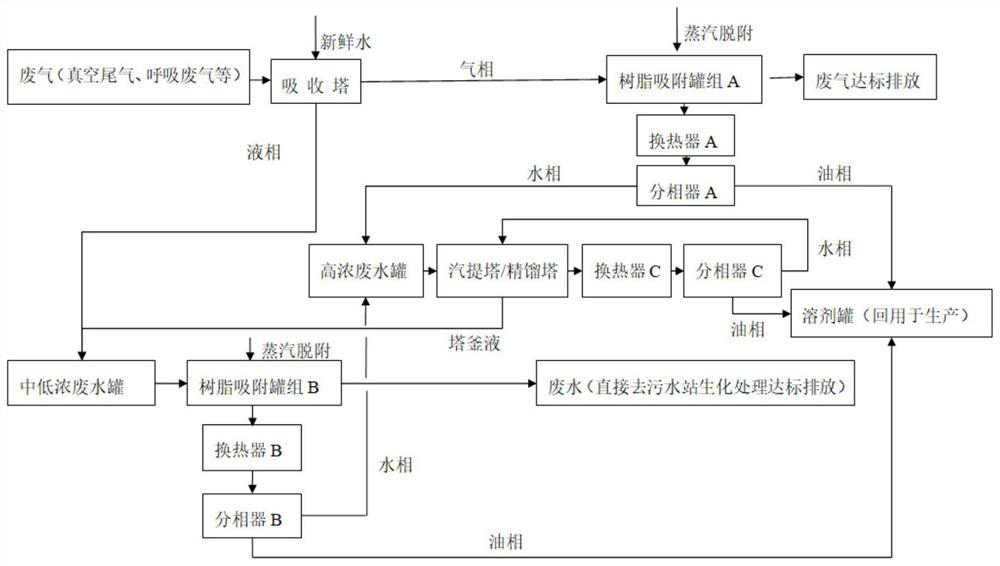

A technology for chemical production and clean production, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc. It can solve the problems of difficult wastewater treatment and low recovery efficiency of volatile gases, and achieve the effect of pollutant emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

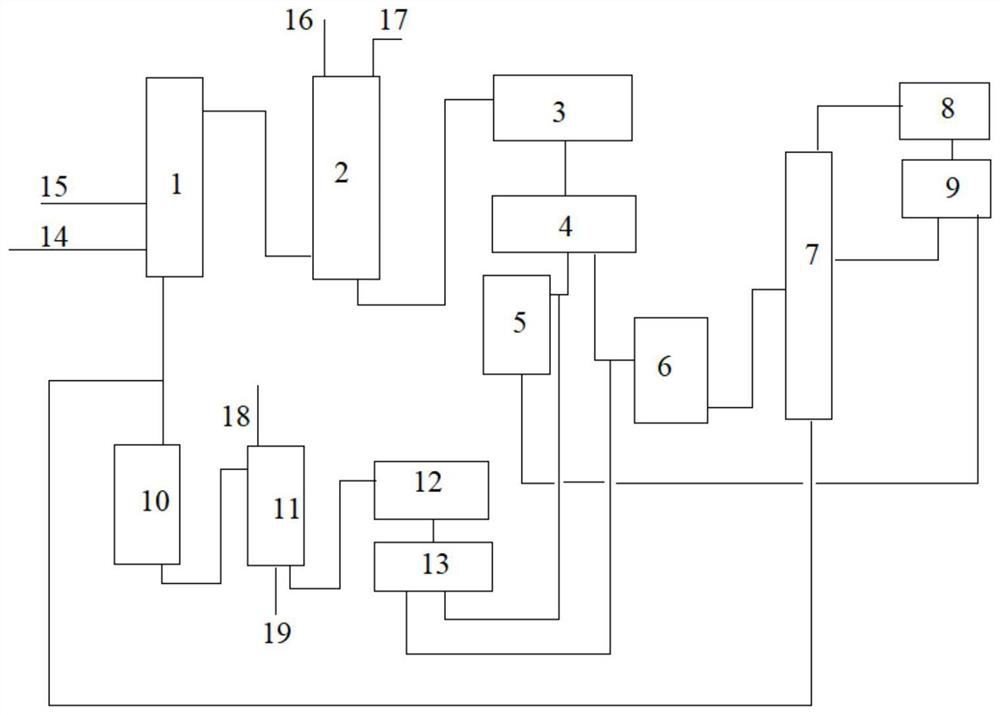

Method used

Image

Examples

Embodiment 1

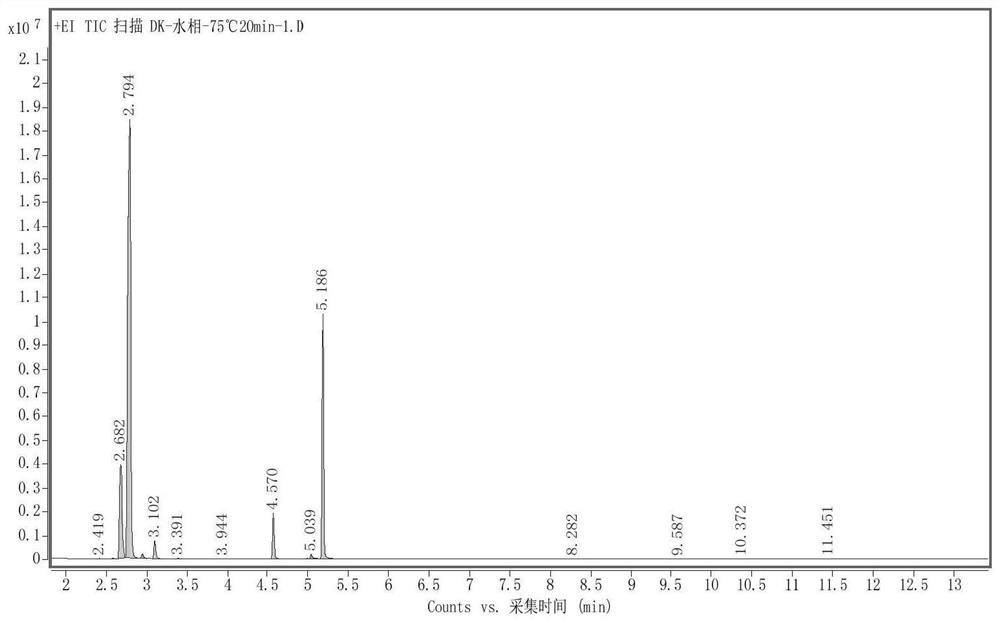

[0069] The invention relates to a process for recovering and treating volatile organic compounds in clean production. The process method of the present invention is used to process the waste gas of epichlorohydrin produced in the production process of epoxy resin. Resin consumption per tank 3m 3 , the adsorption time is 5 hours, and the desorption temperature is 120-140°C.

[0070] The waste gas includes vacuum non-condensable gas and breathing waste gas, and the gas concentration of epichlorohydrin in the waste gas is 2481mg / m 3 , also contains a small amount of organic gas soluble in water (the volume percentage of oxychloropropane in the waste gas is greater than 95%), and the temperature of the waste gas is 20-50°C. The waste gas is first washed and absorbed by the absorption tower, and the washed waste gas is absorbed by the first adsorption resin tank group and then exhausted. The concentration of epichlorohydrin in the exhaust gas is 6.169mg / m 3 , achieve up-to-standa...

Embodiment 2

[0077] The invention relates to a process for recovering and treating volatile organic compounds in clean production, using the process method of the present invention to process waste gas whose main component is butanol. The concentration of butanol in the exhaust gas is 1936mg / m 3 , The exhaust gas temperature is 20-50°C; it also contains a small amount (less than 5% by volume) of water-soluble components and high-boiling components.

[0078] The desorption temperature of the first and second resin adsorption tanks is 120-140°C, and the desorption time is 1h; the concentration of butanol in the gas discharged up to the standard is 1mg / m3 3 ; The waste water COD of the waste water in the high concentration waste water tank: 113273mg / L, the liquid COD of the tower kettle: 36831mg / L. The recovery of butanol was 99.2%.

Embodiment 3

[0080] A recovery and treatment process for volatile organic compounds in clean production uses the process method of the present invention to process waste gas whose main component is dichloromethane. The concentration of dichloromethane in the exhaust gas is 3421mg / m 3 , the exhaust gas temperature is 20-50°C; it also contains a small amount of water-soluble components such as hydrogen chloride (content is less than 5%).

[0081] The desorption temperature of the first and second resin adsorption tank groups is 120-140°C, and the desorption time is 1h; the concentration of dichloromethane in the gas discharged up to the standard is 1mg / m3 3 ; The waste water COD of the waste water in the high-concentration waste water tank: 163821 mg / L, and the liquid COD of the tower kettle: 46239 mg / L. The recovery of dichloromethane was 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com