Method for preparing oriented MOF (Metal Organic Framework) film with assistance of steam and separation application

A MOF, orientation technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve problems such as difficulty in balancing membrane flux and separation factor, membrane thickness, and complex membrane preparation process, and achieve good long-term performance. Separation stability, simple and quick preparation method, and excellent separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

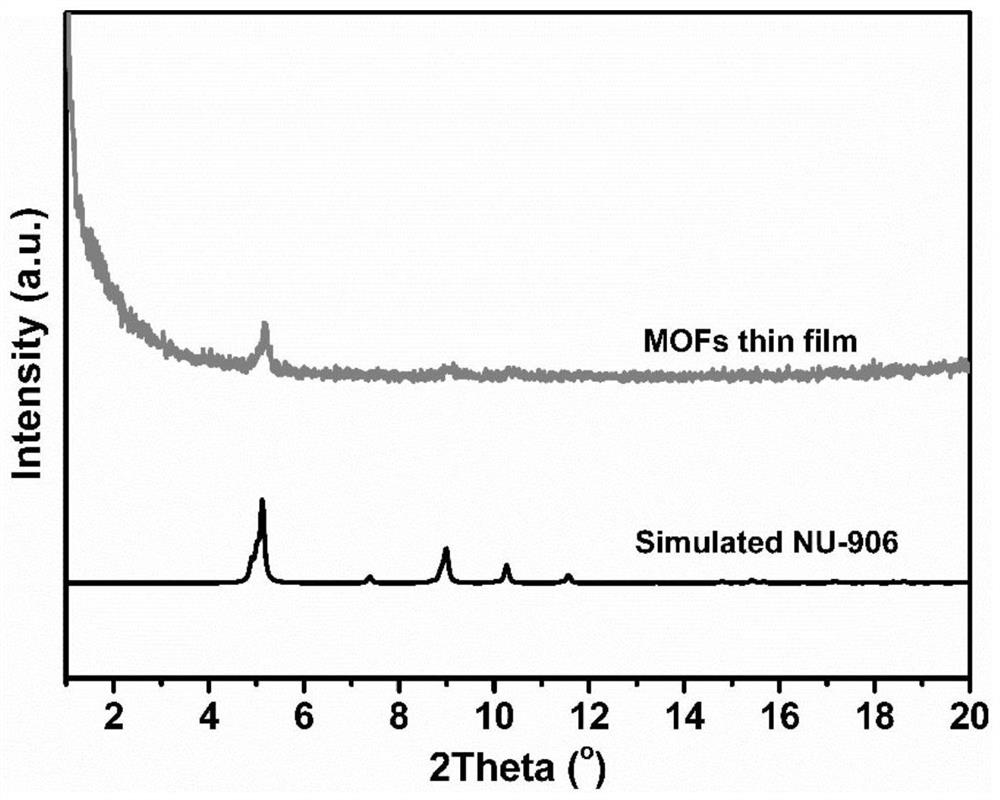

[0033] (1) Liquid A: Dissolve 58.5 mg of zirconium chloride and 24 mg of benzoic acid in 1.8 mL of N,N-dimethylformamide, heat at 80°C for 1 hour, and cool to room temperature; Liquid B: 36 mg of 1,4-dibromo -2,3,5,6-Tetracarboxyphenyl-substituted benzene was dissolved in 1.8mL N,N-dimethylformamide; Mix the prepared A solution, B solution and 288mg benzoic acid, and heat at 100°C for 2- 72h to obtain white powdery NU-906 particles, ready to use;

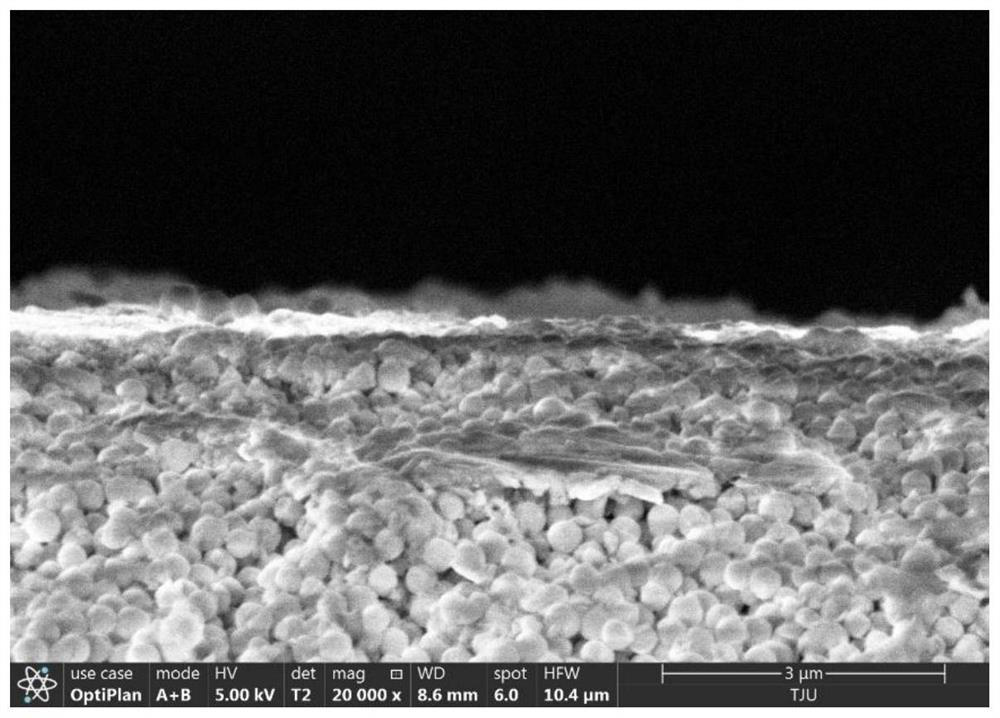

[0034] (2) After smoothing the surface of the self-made silica carrier with sandpaper, coat 50nm silica particles and calcinate at 550°C for 5 hours to obtain a silica carrier with a smooth and flat surface;

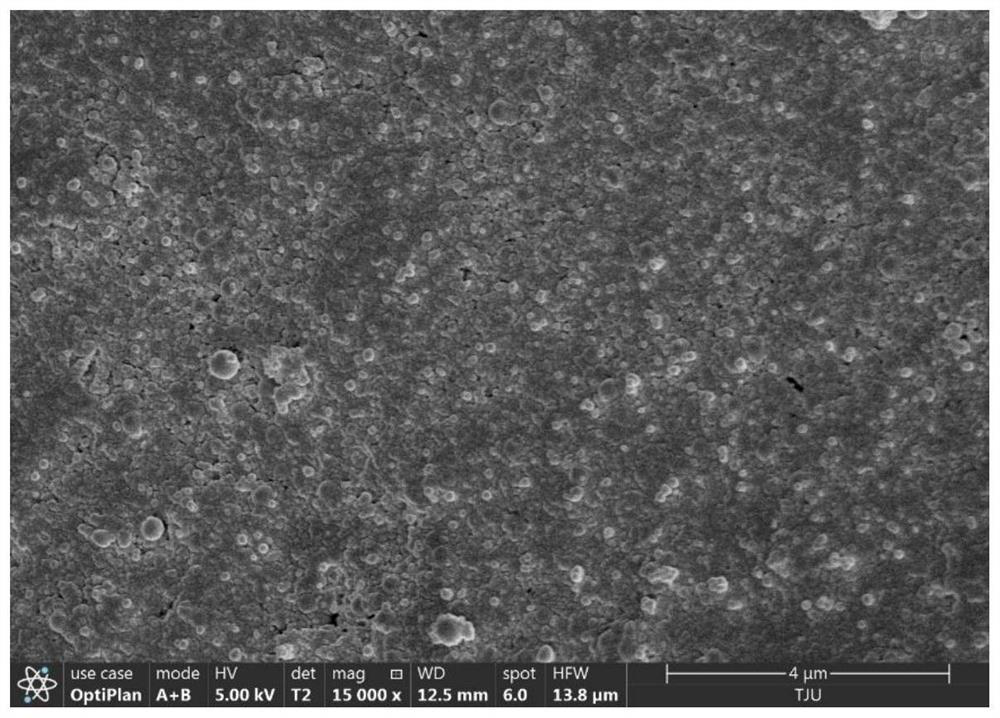

[0035] (3) Disperse 2.5mg NU-906 seed crystals in 2.6mL N,N-dimethylformamide so that the loading capacity of a single chip is 5mg / cm 2 , assembled on a silica carrier by wet coating to form a dense NU-906 layer, ready for use;

[0036] (4) Place the pre-coated NU-906 carrier in a polytetrafluoroethylene lining with a bracke...

Embodiment 2

[0046] (1) Liquid A: Dissolve 58.5 mg of zirconium chloride and 24 mg of benzoic acid in 1.8 mL of N,N-dimethylformamide, heat at 80°C for 1 hour, and cool to room temperature; Liquid B: 36 mg of 1,4-dibromo -2,3,5,6-Tetracarboxyphenyl-substituted benzene was dissolved in 1.8mL N,N-dimethylformamide; Mix the prepared A solution, B solution and 288mg benzoic acid, and heat at 100°C for 2- 72h to obtain white powdery NU-906 particles, ready to use;

[0047] (2) After smoothing the surface of the self-made silica carrier with sandpaper, coat 50nm silica particles and calcinate at 550°C for 5 hours to obtain a silica carrier with a smooth and flat surface;

[0048] (3) Disperse 10mg NU-906 seed crystals in 2.6mL N,N-dimethylformamide so that the loading capacity of a single chip is 20mg / cm 2 , assembled on a modified silica carrier by wet coating to form a dense NU-906 layer, ready for use;

[0049] (4) Place the pre-coated NU-906 carrier in a polytetrafluoroethylene lining with...

Embodiment 3

[0059] (1) Liquid A: Dissolve 58.5 mg of zirconium chloride and 24 mg of benzoic acid in 1.8 mL of N,N-dimethylformamide, heat at 80°C for 1 hour, and cool to room temperature; Liquid B: 36 mg of 1,4-dibromo -2,3,5,6-Tetracarboxyphenyl-substituted benzene was dissolved in 1.8mL N,N-dimethylformamide; Mix the prepared A solution, B solution and 288mg benzoic acid, and heat at 100°C for 2- 72h to obtain white powdery NU-906 particles, ready to use;

[0060] (2) After smoothing the surface of the self-made silica carrier with sandpaper, coat 50nm silica particles and calcinate at 550°C for 5 hours to obtain a silica carrier with a smooth and flat surface;

[0061] (3) Disperse 20mg of NU-906 seed crystals in 2.6mL N,N-dimethylformamide to make the loading capacity of a single chip 40mg / cm 2 , assembled on a modified silica carrier by wet coating to form a dense NU-906 layer, ready for use;

[0062] (4) Place the pre-coated NU-906 carrier in a polytetrafluoroethylene lining with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com