High-thermal-conductivity insulating cooling fin for new energy battery and preparation method of high-thermal-conductivity insulating cooling fin

A thermal insulation layer, high thermal conductivity technology, applied in the coating and other directions, can solve the problems of leakage, slow water heat dissipation, trouble, etc., to achieve the effect of good heat dissipation, improve heat dissipation, and reduce the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

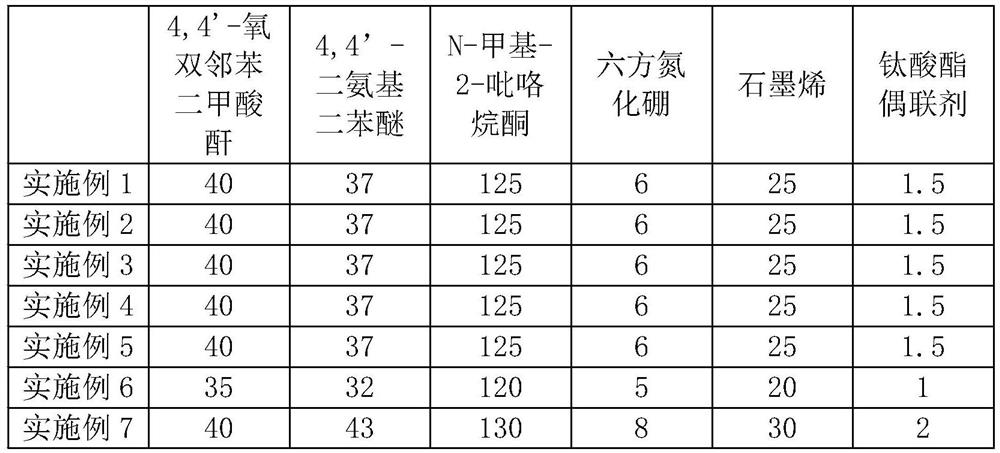

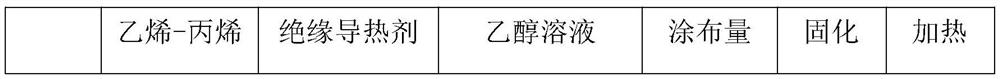

Examples

preparation example 1

[0052] A kind of insulating heat-conducting agent, is made by following steps:

[0053] Step 1: Weigh 1Kg of mica, 0.6Kg of silicon powder, 0.4Kg of kaolin and 65Kg of xylene, put them into an ultrasonic wave and vibrate for 8 minutes to obtain a mixture A;

[0054] Step 2: Weigh 37Kg of methylphenyldimethoxysilane and 1.3Kg of tetramethyldivinyldisiloxane, mix well, add the mixture A obtained in step 1 into the reaction kettle, and stir well , heated to 55°C to obtain mixture B;

[0055] Step 3: Weigh 4Kg mass fraction of 2% sodium hydroxide solution, add it dropwise to the mixture B obtained in step 2, stir evenly, heat to 75°C, hydrolyze for 2.5h, heat up to 85°C, and distill at atmospheric pressure , reacted for 5 hours, raised the temperature to 100°C, and then distilled under reduced pressure for 0.8 hours to remove the solvent and small molecule products, and then added absolute ethanol for washing to obtain an insulating and heat-conducting agent.

preparation example 2

[0057] A kind of insulating heat-conducting agent, is made by following steps:

[0058] Step 1: Weigh 0.5Kg of mica, 0.3Kg of silicon powder, 0.2Kg of kaolin and 50Kg of xylene, put them into an ultrasonic wave and vibrate for 8 minutes to obtain a mixture A;

[0059] Step 2: Weigh 35Kg of methylphenyldimethoxysilane and 1.1Kg of tetramethyldivinyldisiloxane, mix well, add the mixture A obtained in step 1 into the reaction kettle, and stir well , heating up to 50°C to obtain mixture B;

[0060] Step 3: Weigh 3Kg of 1.5% sodium hydroxide solution, add it dropwise to the mixture B obtained in step 2, stir evenly, heat to 70°C, perform hydrolysis reaction for 2h, heat up to 80°C, and distill at normal pressure, After reacting for 4 hours, the temperature was raised to 90° C., and then vacuum distillation was carried out for 0.5 hours to remove the solvent and small molecule products, and then anhydrous ethanol was added for washing to obtain an insulating heat-conducting agent. ...

preparation example 3

[0062] A kind of insulating heat-conducting agent, is made by following steps:

[0063] Step 1: Weigh 1.5Kg of mica, 0.9Kg of silicon powder, 0.6Kg of kaolin and 50Kg of xylene, put them into an ultrasonic wave and vibrate for 10 minutes to obtain a mixture A;

[0064] Step 2: Weigh 39Kg of methylphenyldimethoxysilane and 1.4Kg of tetramethyldivinyldisiloxane, mix well, add the mixture A obtained in step 1 into the reaction kettle, and stir well , heated to 60°C to obtain mixture B;

[0065] Step 3: Weigh 5Kg of 2.0% sodium hydroxide solution, add it dropwise to the mixture B obtained in step 2, stir evenly, heat to 78°C, perform hydrolysis reaction for 3h, heat up to 95°C, and distill at normal pressure, After reacting for 6 hours, the temperature was raised to 110° C., and then vacuum distillation was carried out for 0.5 hours to remove the solvent and small molecule products, and then anhydrous ethanol was added for washing to obtain an insulating heat-conducting agent.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com